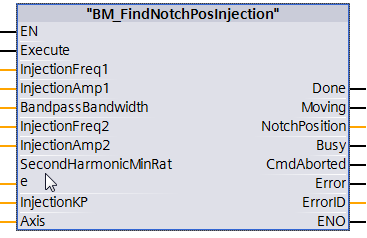

Description

The function "BM_FindNotchPosInjection" carries out a notch position search (parameter 127.008.00) by the injection processing; it is not required that the axis is freely movable in order to carry out this measurement; after measuring successfully the redetermined notch position is displayed.

The redetermined value already is valid in the RAM controller. A takeover into the controller flash can be made with the BM_DataSetHandling.

Further information referring to the notch position search is to be found in the "Parameter manual of the basic unit bmaXX 5000" chapter 3.9.8.

|

Parameter input |

Data type |

Description |

|

Execute |

BOOL |

Edge-sensitive execution |

|

InjectionFreq1 |

REAL |

Injection frequency 1 [1/s] |

|

InjectionAmp1 |

REAL |

Injection amplitude 1 [V] |

|

BandpassBandwidth |

REAL |

Bandpass bandwidth [1/s] |

|

InjectionFreq2 |

REAL |

Injection frequency 2 [1/s] |

|

InjectionApmp2 |

REAL |

Injection amplitude 1 [V] |

|

SecondHarmonicMinRate |

REAL |

Minimum rate second harmonic [%] |

|

InjectionKP |

REAL |

Injection Kp [1/s] |

|

Parameter output |

Data type |

Description |

|

Done |

BOOL |

Notch position search successful |

|

Moving |

BOOL |

Notch position search is running. |

|

Busy |

BOOL |

Parameter Read/write active. |

|

CommandAborted |

BOOL |

Abort by another motion control command, BM_Stop or error stop |

|

Error |

BOOL |

Parameter Read/write error; Error ID is valid |

|

ErrorID |

DWORD |

Communication error ID Siemens error list |

|

Parameter Input and output |

Data type |

Description |

|

Axis |

UDT |

BM Motion Control Axis Variable |

Description

Before activating the command "BM_FindNotchPosRAFS" BM_Power must be switched off and the axis must not be freely movable.

The command "Execute = 1" switches on the Axis notch position search. By an edge-sensitive execution all of the input values are taken over and the command is started at the axis. A new command switching requires a change from FALSE to TRUE at the input "Execute" whereby this change can be carried out at the executing time of the command.

Movement command:

The edge-sensitive execution in switched-off BM_Power state. The execution of abort is aborted with BM_Stop, missing operational readiness or Errorstop. In the result message, only one of the output bits Done, Busy, CommandAborted is active

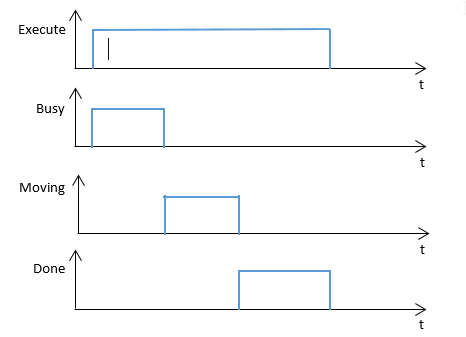

Edge-sensitive execution:

Diagram of an edge-sensitive execution:

Diagram 1:

State

control by BM_ReadStatus:

Off state: Standstill.

After state: -

Recommended task: OB1.

Note:

"BM_Power" and other function block must be switched off and the axis must be freely movable.

A command from "BM_FindNotchPosInjection” must not be activated before a command from another function block has been not successfully executed.

If an error occurs during the command execution, the error must be reset with “BM_Reset”. Function block command will be executed successfully at "BM" .AXIS [x] .DRIVE.BM_AXIS_STATUS.ParmRW_Active = 0.

Input Execute:

TRUE: Edge-sensitive execution, the input parameters are taken over and the notch position search is activated.

FALSE: No execution or resetting of the FC outputs of Error & Error ID.

Input InjectionFreq1:

The parameter InjectionFreq1 can set the frequency of the HF voltage injected in the motor in step 1, unit 1/s.

Minimum: 0.0 [1/s], if 0.0<InjectionFreq1<=0.1

Maximum: 4000.0 [1/s]

Default: 1000.0 [1/s], if InjectionFreq1=0.0

Input InjectionAmp1:

The parameter InjectionAmp1 can set the amplitude of the FH voltage injected in the motor in step 1, unit V.

Minimum: 1.0 [V], maximum: 400.0 [V]

Default: 100.0 [V], if InjectionAmp1 =0.0

Input BandpassBandwidth:

The parameter BandpassBandwidth can set the bandwidth of the filter, which are used to deactivate the HF shares of motor currents Id, Iq.

Minimum: 1.0 [1/s], maximum: 500.0 [1/s]

Default: 50.0 [1/s], if BandpassBandwidth =0.0

Input InjectionFreq2:

With the parameter InjectionFreq2 the frequency of the voltage is set, which is injected during the pole position determination in step 2 in the motor, to cause 180° of ambivalence ; this frequency exclusively takes over the following values to: 62.5 Hz; 125Hz; 250Hz; 500Hz.

Minimum: 0.0 [1/s], if 0.0<Parameter InjectionFreq2<=0.1

Maximum: 1000.0 [1/s]

Default: 250.0 [1/s], if parameter InjectionFreq2=0.0

Input InjectionAmp2:

The parameter InjectionAmp2 can set the amplitude of the HF voltage injected in the motor in step 2.

Minimum: 1.0 [V], maximum: 400.0 [V]

Default: 280.0 [V], if parameter InjectionAmp2=0.0

Input SecondHarmonicMinRate:

The minimum permitted percentage share of the second harmonic I2 of the injected HF current with regard to the fundamental current I1 in the second step

Minimum: 0.0 [%], if parameter 0.0 <SecondHarmonicMinRate =0.1

maximum: 100.0 [%]

Default: 5.0 [%], if Parameter SecondHarmonicMinRate =0.0

Input InjectionKP:

The parameter InjectionKP sets the proportional gain Kp and the integral time Tn of the associated PI compensating controller to the injection process.

Minimum: -1.00000e+10, maximum: +1.00000e+10

Default: 80.0, if parameter InjectionKP =0.0

Output Done:

TRUE: Notch position search is executed. Drive state changes from Enable operation to

Ready-to-switch-on.

FALSE: Not activated.

Output Moving:

TRUE: Notch position search is running.

FALSE: not activated.

Output Busy:

TRUE: The service communication of the parameter Read/write active.

FALSE: Not activated.

Output CommandAborted:

TRUE: Abort due to another motion control command, BM_Stop command, error stop or a missing operating availability to BM_Power.

FALSE: Not activated.

Output Error:

TRUE: An error at the service communication of the parameter Read/write is available. Information to error ID is valid and error information, refer to S7 in the manual.

FALSE: No error activated.

Output ErrorID:

The information of service communication error (detailed information refer to S7 in the manual)

Input and output Axis:

Symbolic BM Motion Control axis variable of an UDT type.

While programming the data module template DDB5 (symbolic "BM") it is to be written with the following symbol text: "BM".AXIS[x] (x is drive axis number).