Machine Templates

For your head start in the development process

Each application is unique, yet does not necessarily mean that everything has to be reinvented — quite the opposite in fact: For the purpose of modular engineering, the aim is to fall back on the tried-and-tested and to concentrate on the specific task. Baumüller offers templates for different industry solutions whose software contains a large number of the functions required in the respective machines. The machine programmer no longer has to worry about the basics, but can use the time saved wholly for process programming.

► Learn more about Smart Engineering in the Baumüller Motion Arena!

Head start in the development process

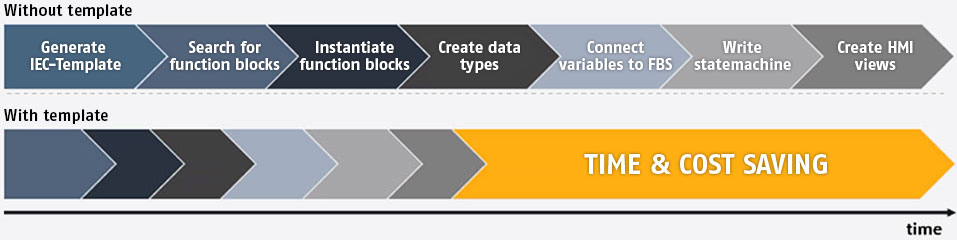

Each developer has only a certain number of productive working hours for a project. If the effort spent on setting up the project and integrating frequently used machine functions is reduced by using templates, significantly more time is available for the project-specific programming. A win-win situation: The developer can concentrate on the sophisticated parts of the project and the machine manufacturer can increase their competitive advantage.

How the templates work

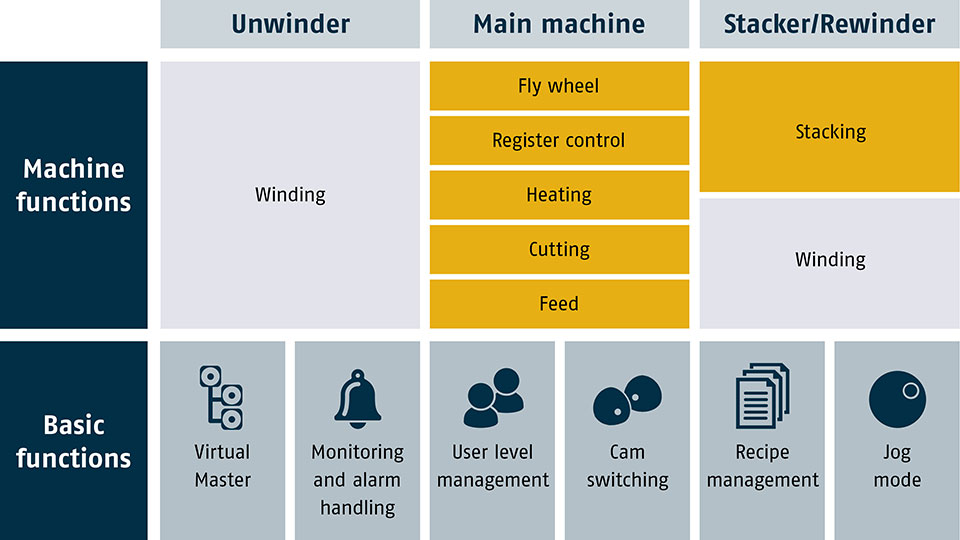

The principle of software templates from Baumüller is easily explained: Basic functions such as recipe management or user-level management do not have to be set up by the developer for a new project, rather they simply have to select and parameterize them at the start. Routine tasks such as instancing blocks or linking variables to the modules cease to be necessary and the developer saves lots of time, particularly at the start of the project.

The templates also contain frequently used machine functions. These only have to be adjusted to the respective application. The time saved can be used later for the individual programming or to improve the machine programming. or to reduce the time-to-market. The templates not only contain the individual libraries, but also general templates, for example, for the implementation of the visualization or the fault management. Furthermore, depending on the template, it also contains industry-specific functions such as print mark detection.

Example: Web & Foil - print mark detection

The example of print mark detection is ideal for explaining the principle of the templates. Print marks are used in machine automation to reliably register film, foils or paper sheets to and to position them correctly. If the print mark is detected correctly, the subsequent machining step – such as printing, folding or cutting – is initiated in the correct position.

This requires register control, which controls the side and longitudinal register, in a printing unit ,for example, with maximum precision. The “Web & Foil” template for web processing machines contains the “TouchProbe” function as the basis for subsequent print mark detection, on which the register control can be based. The programmer only has to integrate the “adjustment”, as this is machine-specific and is therefore not included in the template (see figure).

In addition to the basic functions, the template also contains the functions for the individual process steps of a standard machine

An important part of register control is the TouchProbe function block. This function can be used to measures spacings and/or lengths in order to detect the exact position of a print mark by means of a fast digital input on the converter. The function saves the current encoder position with a digital signal and calculates the spacing and length from the measured positions. This information is transferred to the control unit, in order to determine the position on the material, at which the print has to be applied or the cut has to be set. Any disturbance variables are compensated for at the same time.

The touch probe function contained in the template is completely preconfigured. The parameterization can be carried out with a user-friendly interface (see figure).

The following parameters, among other things, can be entered:

- Does the motor turn forwards or backwards?

- Which digital input on the controller is to be used?

- Which of the controller’s encoder inputs should be used?

Convenient parameter input instead of programming in the source code – the TouchProbe function block for print mark detection in the “Web & Foil” template

Convenient parameter input instead of programming in the source code – the TouchProbe function block for print mark detection in the “Web & Foil” template

The settings can then be tested immediately. The block tests the functionality and calculates automatically the values for the size of the product, the distance between the products, etc. The optimum settings for the machine can therefore be determined and accepted.

The complete activation in the template is already preprogrammed and only has to be configured. Following successful parameterization the template must be connected to the machine and adjusted to the machine.

Expansion is easily achieved

Depending on the application, the program can be expanded at any time: For example, if a second touch probe is to be used in the machine, the template only has to be copied and also parameterized. If the function is not used in the machine, the block can be simply deactivated or deleted.

Faster start

What also facilitates the start – the Baumüller templates are delivered as an executable .exe file and contain all the files required in ProMaster and ProProg, the visualization templates and the instructions for use. The installation package sets up the development PC (e.g. ProMaster), and the PLC fully automatically. The developer can start immediately, without having to transfer files into the system manually.

Project-specific programming

Only the process part is still needed in the software to implement the whole machine. This can either be completely freely programmed or can be done using the available Baumüller software libraries. This step decides the fundamental competitive advantage of the machine manufacturer – this is where the industry and process know-how is incorporated into the software. Other functions can also be integrated in this step, for example, optical systems such as cameras or linking to a conveyor belt or a robot. The machine manufacturer can implement this themselves or can also be undertaken by the Baumüller specialists if necessary. In the past, many projects have also been implemented by system integrators.

Baumüller therefore offers machine manufacturers the opportunity to concentrate on their core processes and enables a platform-independent software strategy for its customers – without having to be dependent on a supplier by releasing the process know-how. A major advantage, especially for companies that operate in global competition.

The developer saves lots of time, particularly at the start of the project

The developer saves lots of time, particularly at the start of the project