Energy-efficient drive solutions for servo-hydraulic presses

Hydraulic presses have substantial advantages compared to conventional mechanical presses, such as higher tonnages, longer stroke lengths and a compacter design. Furthermore, they offer the user enormous additional flexibility. However, conventional hydraulic presses fed by standard motors have poorer energy efficiency.

With the Baumüller drive solution consisting of highly dynamic servo motors and compact converters, you not only benefit from the advantages of the hydraulics, but also from the efficiency of the servo drive technology. Thanks to the servo pump drive software, at the same time you have an immediately usable and flexible solution for the pressure and flow rate control of your hydraulic press. We assist you with the engineering by designing the motor and drive and, if you wish, with the installation and commissioning worldwide.

- Dimensioning

- Simulation

- Commissioning

- DSD2 servomotors

- Direct pump attachment solutions

- Servo drives mountable side-by-side or standalone

- Intelligent pressure/quantity control

- Pump protection functions

- Condition monitoring of pump leakage and sensor drift

With its components and services, Baumüller offers a broad scope of drive system for servo-hydraulic presses. As a drive and automation manufacturer, we have many years of experience in equipping servo-hydraulic applications, and as a full-range supplier, we are at your side from the planning through to commissioning and service.

Benefits of hydraulic presses compared to conventional mechanical presses

Compared to conventional presses, hydraulic presses are the winners, particularly in terms of high pressing forces and flexibility. With Baumüller high-performance servo pumps and matching drive technology, the processes of hydraulic presses can be optimized with regard to cycle time, repeatability, energy consumption, and environmental compatibility.

Precisely tailored to our customers: From the electric motor through to the complete drive system

Baumüller offers the exact service you require - from individual motors and components to the overarching drive system. We always support your precise needs. Baumüller is not only a supplier of drive systems, but also a partner for the machine building.

New machines / retrofit

from the motor to the overall system

Press sizes

customized

Press type

Hydraulic presses

Lifecycle management

for system optimization

Whether refurbishment or modernization – Baumüller offers you the perfect drive solution for your servo-hydraulic press.

Servo-hydraulic drive system – Baumüller scalable technology

Our servo-hydraulic solution includes the complete main drive system with servo motors and direct pump attachment or classic attachment via coupling and pump support, servo converter and power supply unit, including control cabinet construction, and an extensive software package specially for servo pumps. The drive unit is configured individually depending on the required power.

The drive system is linked to a higher-level control system via standard fieldbus interfaces or analog signals, whereby the machine integration is time-saving and simple.

The DSD2 servomotor series has very low torque of inertia, in order to provide the necessary dynamics for precise pressure control during the forming process. The hydraulic pumps can be attached directly to the servo motors, thanks to the different shaft and flange options. By removing the need for a coupling and pump carriers, the overall length, noise emission and time needed for the assembly are reduced. We also enable the press power to be divided between multiple motors connected via a master-slave coupling.

With the b maXX 5000 and 6000 series servo converters, Baumüller offers suitable servo drives for high performance classes. The servo drives impress with their compact installation dimensions and offer a broad and scalable selection of optional safety functions. The devices also have the option of energy recovery.

The drive system, made up of servo converters with servo-hydraulic software, enables efficient and flexible servo-hydraulic presses for different areas of application

The drive system, made up of servo converters with servo-hydraulic software, enables efficient and flexible servo-hydraulic presses for different areas of application

A drive system tailored to your needs

Motors with very high power outputs are needed in order to provide the high flow rates needed for servo-hydraulic presses. Master-slave load sharing systems are therefore frequently predestined for this application. To this end, Baumüller drives offer very flexible master-slave linking methods, in order to find the most suitable solution for your application.

How high is the power limit for a single motor? Thanks to the modular b maXX drive electronics and the DS2 main drive motors, up to 200 kW power can be covered by a single motor. If the required power exceeds this limit, load sharing by master-slave systems should be chosen.

The system can be completed by use of the b maxx 5000 and b maXX 5100 rectifier and regenerative feedback units and an energy store designed to precisely meet the customer’s requirements.

Due to the modular use of components, this drive system kit enables us to realize a very wide range of presses with minimum variance in the drive system. This very much simplifies the order process as well as warehousing/replacement part stocks for the customer.

Standard control cabinets through to completely wired special control cabinet

For many years, we have been implementing custom solutions for renowned machine and plant manufacturers - from the standard control cabinet through to the completely wired special control cabinet. You receive everything from us, a single source that can therefore deal optimally with your needs and wishes:

Planning – design – sheet metal production – serial production -

assembly - installation

Drive design with ProSimulation

The digital twin offers many advantages, especially during the engineering phase: The development time is shortened, and the machine can therefore be placed on the market as quickly as possible and functionally reliable. With ProSimulation, Baumüller offers simulation models of its drive components. In addition, Baumüller undertakes the complete design of the design technology for its drive technology.

The simulation model of the servo-hydraulic press in ProSimulation enables efficient drive design and virtual commissioning of the drive system

The simulation model of the servo-hydraulic press in ProSimulation enables efficient drive design and virtual commissioning of the drive system

This offers numerous advantages, particularly for complex applications such as servo-hydraulic presses: For example, the complete drive topology can be mapped in the software, therefore enabling the choice of an efficient and resource-saving drive package. This is made up of the pump, the servo motors, the servo drive technology and the pressure-control strategy of the hydraulic system in conjunction with dynamic movement and force profiles. The simulation creates transparency in the power and energy profiles and maps the drive’s pressure control strategy in detail. This saves time during commissioning and enables more in-depth fault analyses during subsequent operation.

Software solutions for servo hydraulics

The servo-hydraulic technology module is integrated directly in the servo drive and is fundamentally responsible for making sure that the advantages of the servo-hydraulics are used to maximum effect. The heart of the software is the flexible pressure and flow rate control in a controller cycle time of only 125 µs for maximum dynamics and precision. Thanks to intelligent feed forward pressure controls, the control adapts itself to different hydraulic ranges and thus achieves outstanding pressure adjustment performance. Parameterization of the servo drive including servo-hydraulic functions is fully embedded in the ProDrive user interface. The guided commissioning makes fast commissioning possible, even without in-depth programming knowledge or detailed servo drive technology know-how. The graphic user interface screens enable logical and clear operation.

The commissioning and optimization can also be undertaken as a service by the Baumüller experts, who have many years of experience in the application of servo-hydraulics systems and thus integrate the system into the machine optimally. In addition to the excellent control strategy and easy handling, the latest Baumüller Software V2 + for servo-hydraulic systems also includes numerous protection and monitoring functions that further enhance the performance and reliability of the system.

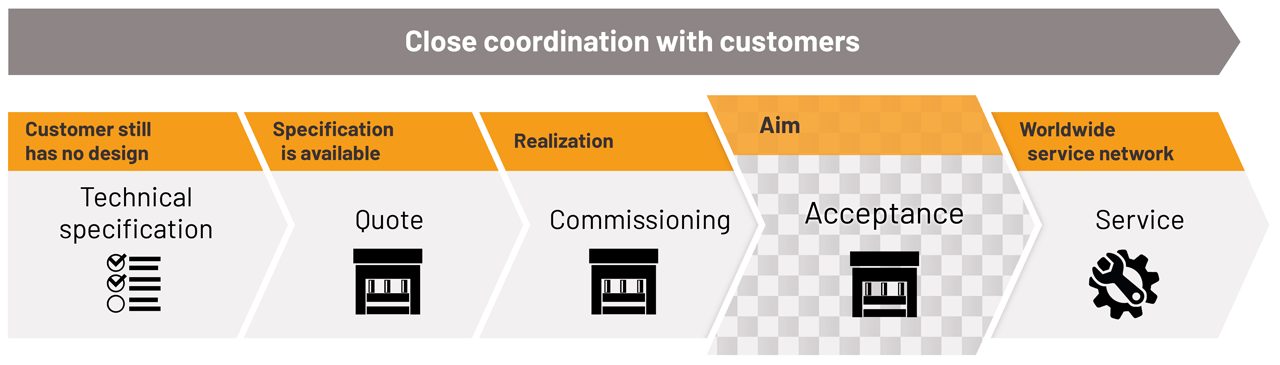

Your path to a qualified quote

You would like a no-obligation consultation or quote? Then contact our experts.

We discuss the relevant technical details with you and together we define the requirements. Only then do we undertake the qualified design of the complete drive system. After checking the specifications, you receive a qualified quote from us.

Baumüller is your partner for the production-ready design and optimization of your drive system. As a non-group-affiliated, mid-sized company, we are able to respond to the wishes of your customers quickly and efficiently with innovative drive solutions. This makes us the perfect partner for challenging projects and future technologies.

Write us a message, our sales experts will be happy to advise you.

Our components for servo-hydraulic presses:

Downloads

Automation

ProMaster, Motion Control, IoT Industry 4.0, b maXX HMI, I/O systems