Basics: Electric motor

Read min.

The term electric motor includes all motors that are driven by electromagnetic forces. In these motors, electrical power is transformed into mechanical power to produce a movement. In most cases, this is a rotation, which is forwarded mechanically by a shaft and thus drives a machine. The electric motor is used in vehicles, from trucks to ships, as well as in numerous industrial machines through to the conventional fan for household use.

In many highly specialized areas of use the electric motor displaced the combustion engine long before the energy transition began. This is due to the high changeability and flexibility, as well as the significantly more precise controllability, which the drive technology provides. Especially in industry, in many areas there is therefore no alternative to the electric motor when it comes to efficiency and adaptability.

The following post discusses how it works, areas of use and variants – and in detail:

Index

- Definition of electric motor and relationship to the generator

- How e-motors basically work using the example of the direct current motor

- Three-phase AC motors: Variants and advantages

- Influencing of the specifications by certain constructions using the example of servo motors

- Application areas for the electric motor in industry, agriculture, and mobility

- The electric motor: Summary

- Finally: Interesting to know

- Outlook: The role of e-motors in future automation

Definition of electric motor and relationship to the generator

An electric motor is an electromagnetic A-D converter. This designation is extremely precise, as it exactly describes the basic function. Electrical power is converted into mechanical power. The counterpart of this is the generator. This is also an electromagnetic converter but works in precisely the opposite way and converts mechanical power into electrical power. The two counterparts can also be used together to recover energy for the drive via the generator.

How e-motors basically work using the example of the direct current motor

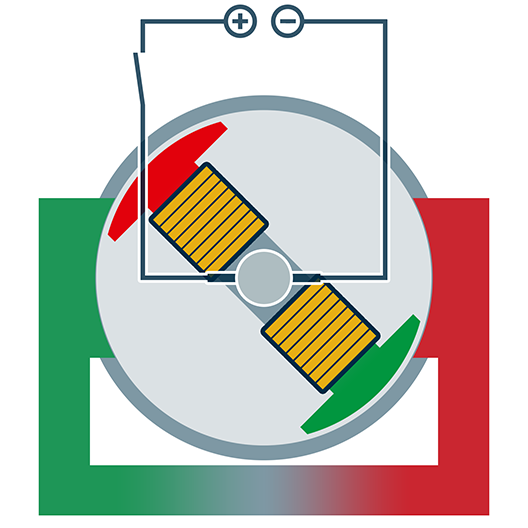

Many variants of the electric motor can be set up, but in all variants it is based on magnetism. The direct current motor has the simplest design: An electromagnetic or permanent magnet stator in interaction with a rotor with a coil wound around it generates an electromagnetic field. The rotor (or armature) is made to move by attraction and repulsion of the opposite poles.

These have opposite polarity. The rotor is positioned between them and is flowed through by electrical current. The rotor polarity is attracted by the stators or is repelled on the other side.

Need for polarity reversal in the direct current motor

In this structure the rotor would now come to rest as soon as the opposite poles of the stator and rotor are next to each other. To stabilize the movement, the polarity must be reversed regularly. This task is undertaken by a so-called commutator. As soon as the negative and positive pole are adjacent to each other at the so-called dead center, the polarity is reversed. The negative and positive pole are now adjacent and repulse each other. The stabilization of this process can generate uniform rotation.

Schematic diagram of the polarity reversal

Enhancement of the basic function

The movements of the rotor can be controlled further by precise control of the polarity and the current flow. On the one hand, an acceleration or deceleration can be controlled, and on the other hand the activation and maintaining of a position. In the simplest form, however, ultimately only the two positions at the dead centers can be maintained and would then also need help to start.

A more complex design is needed for more precise control. To this end, the armature can be given more “arms”. There are, for example, triple armatures or even more in the so-called drum armature. However, an electric motor can be controlled even better and more precisely in the form of a three-phase motor.

Three-phase AC motors: Variants and advantages

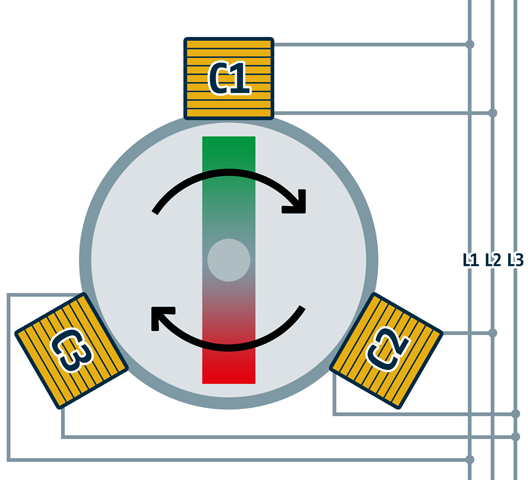

The three-phase motor essentially differs from the direct current motor due to the structure of the stator. This consists of three coils or a multiple thereof. The phases are therefore not displaced by 180 degrees, but by 120 degrees. If current is connected, a rotating field or so-called phase sequence is produced. This electromagnetic field rotates about the center depending on the applied frequency, and acts on the coils of the rotor, which are made to move.

Structure of a three-phase motor

Three-phase asynchronous motors

In the asynchronous motor the rotor can be designed as either a slip ring rotor or as a short-circuited rotor (squirrel cage rotor). In both cases, the rotor follows the interval of the system frequency and therefore that of the circulating rotating field. Due to the action of the applied electromagnetic voltage, this electric motor is also called an induction motor.

The disadvantage of this design is that the rotor follows the rotating field and therefore runs asynchronously – which is therefore also why they are called three-phase asynchronous motors. This generates so-called slip. This describes the time discrepancy between the rotating field and rotor movement. In practice, the slip cannot be completely reduced to zero percent due to the friction contact, however, this can be highly optimized by a different design. Approximately synchronously running asynchronous motors therefore also exist.

For three-phase asynchronous motor applications, very good true running characteristics and a large field weakening range are decisive. Good application examples are work drives for plastic injection machines, special drilling machines in civil engineering, machines with rewinders and unwinders of paper and metal webs, pumps, fans, electric vehicles, or machine tools.

Three-phase synchronous motors

The three-phase synchronous motor also functions via a rotating field. However, the rotor is set up differently. Instead of functioning via electromagnetic induction, it operates with permanent magnets. Since here, unlike the asynchronous motor, the use of permanent magnets removes the need for slip or brush contacts, the electric motor runs synchronously.

The design of synchronous electric motors has several advantages. These include:

- Particularly high efficiency – peak values of 95-96 percent at Baumüller

- High power density

- Higher speeds are possible

- Load-independent stability of the stability

- Very compact design is possible

If permanent magnets are used, there is also no wear of the friction contacts, for example, the brushes.

A three-phase synchronous motor is used, among other things, in applications with maximum energy efficiency requirements. Typical applications are, for example, printing machines, packaging machines, textile machines, handling systems and robots.

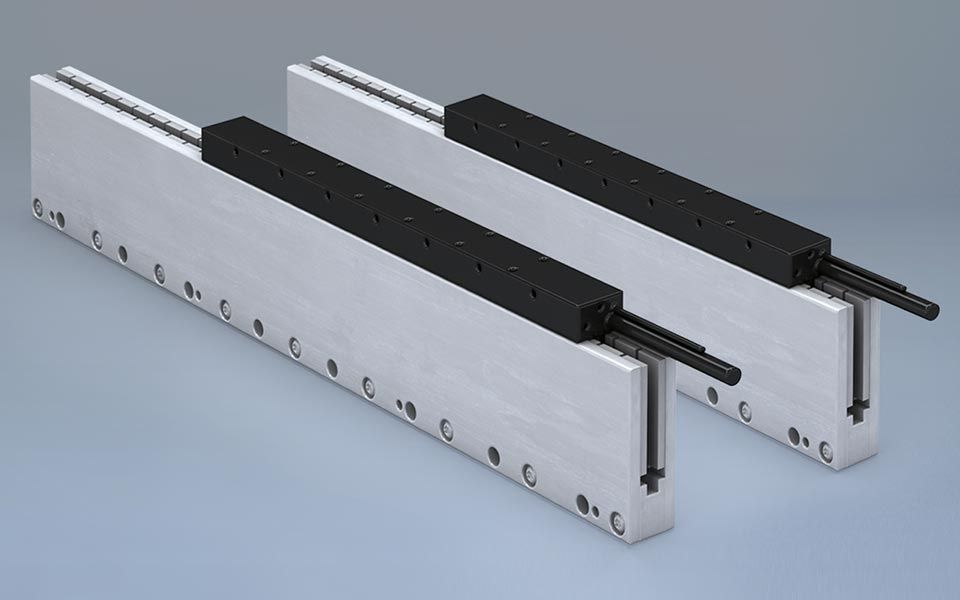

Special case of the linear motor

Linear motors basically function according to the same principles as the three-phase electric motors. However, the stator is not round but is linear. The magnetic field is therefore also not a rotating field. In practice, here a rotor can be pulled back and forth over a straight rail. Curved rails are also theoretically feasible.

Figure of a linear motor

The design is very specialized and is suitable for only a few applications, since theoretically, linear movements can also be realized with a rotating electric motor through indirect transfer. The advantage of a linear motor, however, is the direct drive. High acceleration values can be achieved with these.

Influencing of the specifications by certain constructions using the example of servo motors

The designs described above are mainly used by Baumüller in our servo motors. The variants essentially differ in their controllability. The basic principle of function through electromagnetism remains the same. The variants allow the electric motor to be customized to the specific application in practice and, beyond the basic design, can also be further influenced by other criteria.

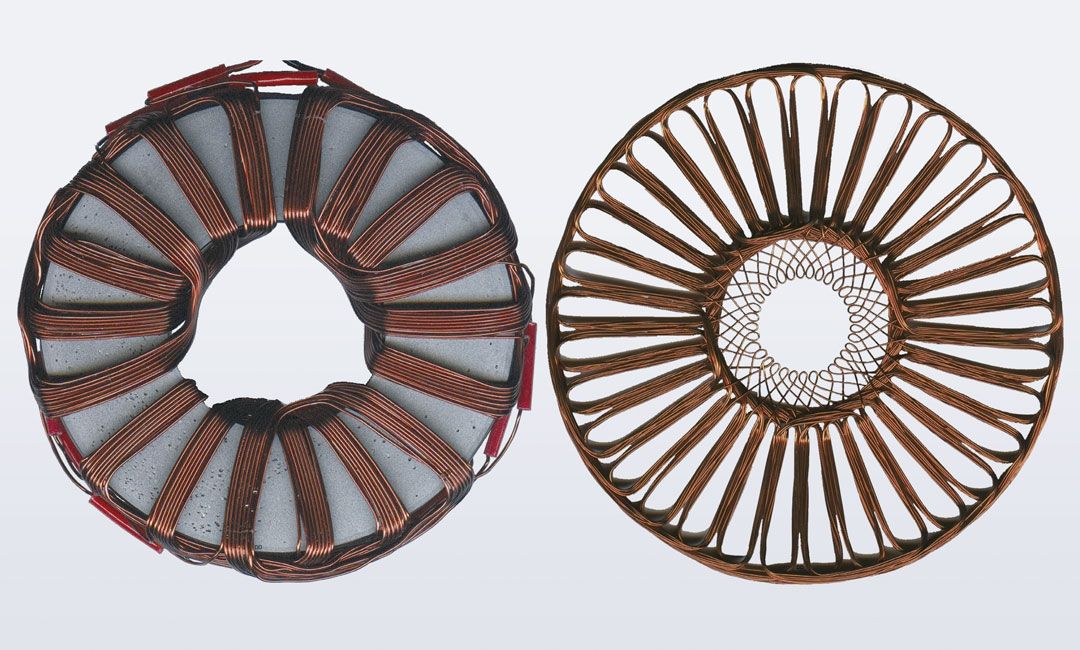

The motor winding

Due to the winding of the conductive wire in the stator, particularly the torque can be influenced. The thinner the wire the more windings that can be achieved. This has significant effects on the electromagnetic rotating field. Because the more windings there are the stronger the magnetic field. This results, for example in our Baumüller DST2 torque motors, in a significant increase in the maximum torque.

Winding in the electric motor

Enormous torques up to 60,000 Nm can be achieved with direct drives, and these operate with significantly less need for maintenance compared to motor-gearing combinations. However, other designs are necessary if high speeds are required, since here the torque decreases. In common high-torque applications, however, high speeds play a secondary role. Examples are winders for metal sheets that, as the reel diameter increases, depend on high torque and reduced speed. Shredders and extruders are also good application examples.

The cooling

The stronger the magnetic field, the more waste heat that is also produced. To make sure that the electric motor and adjacent components do not overheat, suitable cooling is offered in many (but not all) applications. This can take place via surface, air, water, or oil cooling. Liquid cooling has particular significance in servo motors built very close to each other. As these heat each other, cooling is indispensable in most cases. However, space is also gained due to the lack of a need for fans, which would be necessary for air cooling.

The servo controller

The high dynamics of electric motors must also be controlled so that the potential is not wasted. This requires a servo controller, such as the Baumüller b maXX family as an interface between the electric motor or servo motor and the control unit.

b maXX servo-controller for electric motors

Thanks to the control engineering, specific motor positions can be approached exactly and also speeds can be maintained very accurately.

In addition, high acceleration can be achieved. Specific speeds can be activated from rest in a very short time, and it is also possible to switch between specific speeds. The high dynamics and precision maxes out the full potential in the modern electric motor and allows a large number of highly specialized applications. The high precision in particular is indispensable, for example, in robotics. Baumüller servo drives are therefore used, for example, in automated production plants.

Application areas for the electric motor in industry, agriculture, and mobility

While other specifications are necessary for electrified individual mobility, Baumüller electric motors are essentially used in industrial applications. They include, for example:

- Metalworking

- Textile processing

- Packaging machines

- Recycling technology

- Medical technology

- Plastics processing

- Paper and printing machines

- Robotics

Construction machines with electric motor

In addition, Baumüller offers drive systems for e-mobility in the commercial vehicles and work machine sectors. These include, for example, many machines for agriculture and construction, from tractors, excavators, and wheel loaders through to rollers, milling machines or crawler-mounted machines.

The electric motor: Summary

In all designs, the electric motor is based on the principle of electromagnetism. From the simple structure of the direct current motor to the synchronous motor, electric motors can be adapted in particularly versatile ways. In addition, there are specifications further tailored to the individual application. With these, servo motors can be adapted to aspects such as maximum torque, extreme precision, and many other requirements. Baumüller offers tailormade drive solutions for all kinds of different industries and applications, from the electric motor to the servo controller through to the control unit and software.

Finally: Interesting to know

The electric motor has a far longer history than would be assumed today. Evidence exists of initial experiments in the 18th century. At the beginning of the 19th century, the development gathered pace as part of the fundamental study of electricity.

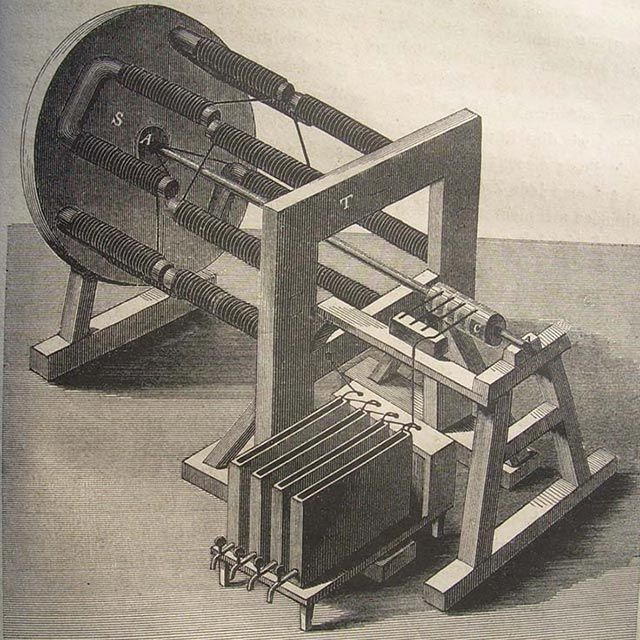

Figure of the first electric motor made by Jacobi (Julius Dub, public domain, via Wikimedia Commons)

The specific use of electromagnetism in drives was, however, still pushed back by combustion engines during the course of the early 20th century.

Yet the physicist Moritz Hermann von Jacobi developed the first practical electric motor in 1834. Sponsored by the Russian Tsar, Nicholas I. in 1838 he operated a boat with a direct current motor for the first time, which was able to travel through St. Petersburg on the River Neva.

Today, Baumüller works on electric motors that are also designed for shipping. With high-torque synchronous motors, the specifications of then and now lie worlds apart. However, the physical operating principle has stayed the same, but continues to be developed further nowadays.

This means that diesel engines for driving the ship’s propeller in shipping can be successively replaced. Inland shipping and ferry operations between fixed charging stations are most suitable candidates. Here you will find more on the topic of the electrical ship propulsion from Baumüller.

Outlook: The role of e-motors in future automation

Compared to other types of drive, such as the combustion engine, the electric motor offers numerous advantages. Several are particularly prominent within the scope of the energy transition, and the topics of environmental and climate protection. The range of advantages extends far beyond this, however. The increasing automation of agricultural and industrial processes is particularly reliant on the electric motor, which has become without alternative in this area.

The high changeability and adaptability of the electric motor makes it a type of drive with a long history and a probably even longer future.

Matthias Beetz

Training Engineer Academy I Baumüller Nürnberg GmbH