Innovative drive solutions for shredders

The most important criteria for recycling machines (shredders) are high machine availability and high throughput with the lowest possible energy consumption. Baumüller has already implemented various drive solutions of single shaft and twin shaft shredders with or without feeding. As a specialist for electric drives with high performance, Baumüller offers high-torque electric drives that enable a reduction in the energy consumption of the shredders by up to 30 percent.

Consisting of both control and drive technology, the Baumüller system solution gives you our know-how in the area of recycling applications while at the same time providing an instantly usable and flexible solution for your machine. We support you with the engineering and will implement the drive, machine control and software for you, completely and entirely according to your wishes. Baumüller also offers optional long-term life cycle management for the shredder’s drive that is individually tailored to your needs and those of your customers. On request, we will also support you with the installation and commissioning of your system anywhere in the world.

- Dimensioning

- Commissioning

- High-torque motors

- Servo drives

- PLC control unit

- Control cabinets

- Load distribution / synchronization

- Block monitoring

- Commissioning mode

- Control interface

- Improved diagnostic possibilities (HMI)

With its components and services, Baumüller offers the largest scope of systems for shredder drives. As a drive and automation manufacturer, we have many years of experience in equipping shredders and, as a full-range supplier, we are at your side from the planning through to commissioning and service.

Advantages of high-torque motors and servo drive technology over conventional hydraulic and electric solutions

By eliminating the hydraulic drive, shredders with high-torque motors offer many advantages: The number of wearing parts is reduced, since susceptible components such as hydraulic hoses and the hydraulic motor are no longer necessary. The biggest advantage is the energy efficiency of the motor, which is very easy to regulate and control. In addition, the high-torque motor’s motor-based characteristics make it a very good match for the shredding process. In addition to the enormous amount of energy saved, the noise level is also reduced, which benefits all employees.

Precisely tailored to our customers: From the high-torque motor to the complete drive system

As a partner, Baumüller supports the implementation of customer-specific solutions with its know-how in drive concepts and automation. Baumüller offers the exact service you require - from individual motors and components to comprehensive drive systems with control technology. We always support your precise needs. Baumüller is a partner for machine manufacturers and a supplier of complete systems.

from the motor to the overall system

customized

Single and multi-shaft shredders

for system optimization

Baumüller offers you the perfect drive solution for your shredder.

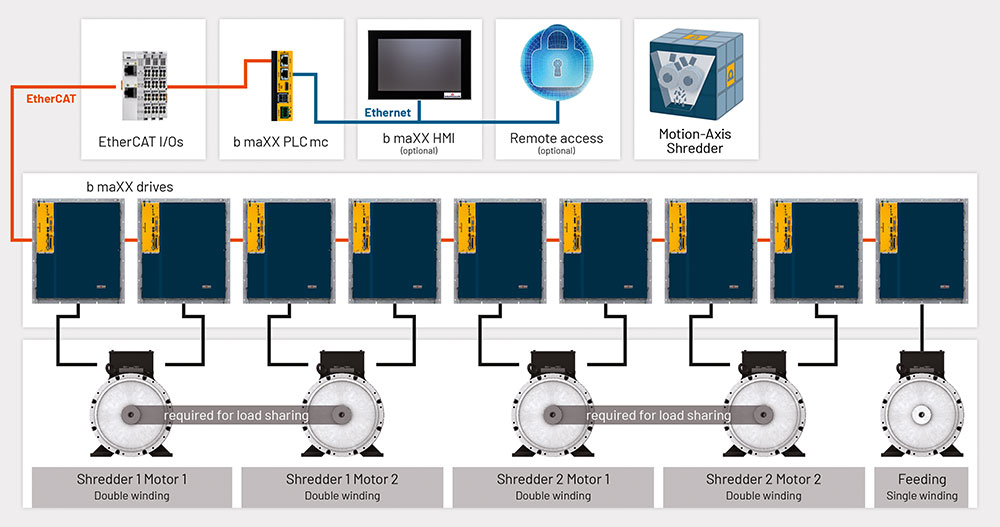

Complete drive system solution – scalable technology from Baumüller

Our system solution includes the complete main drive system with high-torque motors, servo converters, including control cabinet construction, as well as the control technology with hardware and an extensive complete software package specially for shredding plants. The drive unit is configured individually depending on the required power.

Shred & recycle waste with Baumüller & WEIMA

Interview with Stefan Reuß, Project Manager at WEIMA Maschinenbau GmbH

I agree that external content may be displayed to me,

which means that personal data may be transmitted to third-party platforms.

Read more about this in our privacy policy.

In order to provide the high power required for shredding processes, depending on the gear ratio, motors with very high maximum torques are needed. The Baumüller DST2 series high-torque motors are therefore predestined for this application. The motors can be perfectly adapted to the shredder’s requirements thanks to different shaft and flange options. Depending on the power requirements, the shredder shafts are each driven by one or two motors.

With the b maXX 5000 converter family, Baumüller offers suitable servo drives for high power classes. The servo drives impress with their compact installation dimensions and offer a broad and scalable selection of optional safety functions.

On the control level, Baumüller offers the b maXX PLC mc, a combination of industrial PC and classic PLC control unit.

Overall systems consisting of high-torque motors, servo drives, control unit and special visualization enable efficient and productive shredders for different areas of application

Overall systems consisting of high-torque motors, servo drives, control unit and special visualization enable efficient and productive shredders for different areas of application

Everything from a single source: A complete package, tailored to your needs

Baumüller can also supply the right drive system for large shredding systems, such as car shredders. Thanks to the modular b maXX 5500 drive electronics, with the help of multiple-winding systems, even the large motors of the DST2 series can be used and combined to form multi-motor solutions.

Due to the modular use of components, this drive system kit enables us to realize a very wide range of shredders with minimum variance in the drive system. This very much simplifies the order process as well as warehousing/replacement part stocks for the customer.

The circular economy meets energy efficiency: 30 percent lower energy costs thanks to direct drive technology

Standard control cabinets through to completely wired special control cabinet

For many years, we have been implementing custom solutions for renowned machine and plant manufacturers - from the standard control cabinet through to the completely wired special control cabinet. You receive everything from us, a single source that can therefore deal optimally with your needs and wishes:

Planning – design – sheet metal production – serial production – assembly – installation

Software solutions for shredders

Save time and money with our complete software package. The software contains a large number of the required machine functions as well as motion modules for actuating the servo motors, templates for the machine visualization, and functions such as EtherCAT diagnosis, commissioning mode, load balancing, and water cooling control.

Template for Baumüller control unit and drives

Benefits for your machine concept

- Template is fully executable

- Installation package for easy commissioning of the control unit and converter

- Different shredder variants with one template

- Simple integration as a subsystem through prepared interface

- Activation of multiple-winding motors

- Operation of two coupled motors per crushing shaft is possible

- Fast block monitoring to protect the crushing shaft

- Enhanced diagnostic functionality included

- Less wiring work for multiple-winding motors

Your path to a qualified quote

You would like a no-obligation consultation or quote? Then contact our experts.

We discuss the relevant technical data with you and together we define the requirements. Only then do we undertake the qualified design of the complete drive system. After checking the specifications, you receive a qualified quote from us.

Baumüller is your partner for the design and optimization of your drive system. As a non-group-affiliated, mid-sized company, we are able to respond to the wishes of our customers quickly and efficiently with innovative drive solutions. This makes us the perfect partner for challenging projects and future technologies.

Write us a message, our sales experts will be happy to advise you.

Partners and references:

Our components for industrial shredders:

Our services for industrial shredders:

You might also be interested in

-

Software template for industrial shredder control

Downloads

Shredders

Engineering | Hardware | Software