Environmentally friendly and field-proven drives for agricultural machines

Individual drive concepts and industry-specific components for mobile work machinery

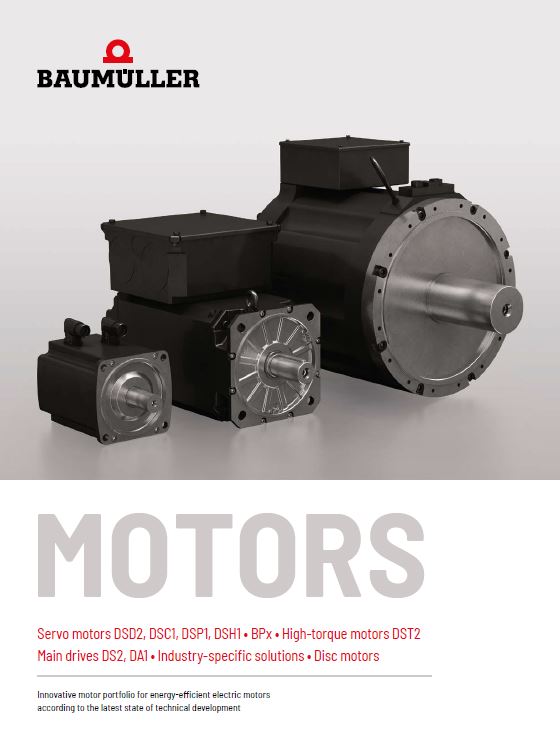

Baumüller is making use of its many decades of experience in the development and production of electric motors and supplying energy-efficient components and comprehensive solutions for hybrid and fully electric drive systems. The low-noise, low-emission drive solutions are used in tractors, semi-trailers, plowing machines, and more.

Baumüller is a reliable partner for the conception, engineering, and development of individual drive concepts for agricultural technology.

Powerful diesel alternative: Efficient electric and hybrid drive solutions

Electric and hybrid agricultural machines are a real alternative to diesel-powered vehicles. With their dynamic and powerful driving performance, electric vehicles master the usual tasks with flying colors and they do this with long operating durations, flexible charging options and minimum noise pollution.

Baumüller’s engineering company, Baumüller Anlagen-Systemtechnik, designs and implements innovative drive concepts for mobile machines and implements them comprehensively, i.e. from battery management and the control system to the user-friendly user interface.

Baumüller equips both main drives and auxiliary drives, e.g. the hydraulic system in the bucket of a wheel loader, with its components and offers the option of integrating the BAUDIS IoT diagnostic and remote maintenance tool in addition to the electric drive system. In this way, necessary service measures can be planned in advance in a targeted way and operating times and loads can be optimally monitored and evaluated. This saves costs and enhances efficiency.

Baumüller customers profit from:

- Experience: Extensive record of successful projects

- Focus on the future: Efficient and powerful hybrid and fully electric drives

- Expertise: System integrator with its own products for E-mobility

- Customized scope of services: From engineering to service, tailored to your requirements

- Specialists in electromobility: From drive design to commissioning

- Full flexibility: Supplier network, adaptations to standard products possible

- Manufacturer independence: System solutions with Baumüller drive technology or in combination with products from other manufacturers

- Worldwide service

Baumüller is your reliable partner for hybrid and fully electric electromobility solutions.

The TADUS tractor as a drive solution: Engineered to be electric from the ground up

In close coordination with TADUS Technologies, Baumüller has developed components that are optimally tailored to the demands of a tractor. The two axle drives, the rear PTO drive, and the drive for the working and steering hydraulics, for example, are from Baumüller’s powerMELA® series. The diesel generator too, which serves as a range extender in the first development step and is composed of the permanent magnet powerMELA® synchronous motor and a diesel engine, was also planned and developed by Baumüller.

Tadus test vehicle | Image: TADUS GmbHThe TADUS tractor is perfectly designed to meet the needs of agriculture. The design of the entire machine, from the axles to the auxiliary drives (PTO and hydraulics) to the chassis, was fine-tuned for electric power transmission. The result makes full use of the potential of the electric motors, achieves the best possible efficiency levels, and guarantees optimum usage properties for the user. With a continuous rated power of 90 kW and a peak power of up to 150 kW, the TADUS tractor performs all the tasks of a conventional tractor with no compromises – while saving energy, cutting down on costs and pollutant emissions, and impressing with its superior driving characteristics.

Tadus test vehicle | Image: TADUS GmbHThe TADUS tractor is perfectly designed to meet the needs of agriculture. The design of the entire machine, from the axles to the auxiliary drives (PTO and hydraulics) to the chassis, was fine-tuned for electric power transmission. The result makes full use of the potential of the electric motors, achieves the best possible efficiency levels, and guarantees optimum usage properties for the user. With a continuous rated power of 90 kW and a peak power of up to 150 kW, the TADUS tractor performs all the tasks of a conventional tractor with no compromises – while saving energy, cutting down on costs and pollutant emissions, and impressing with its superior driving characteristics.

The heart of the TADUS tractor is the drive train , consisting of

- Management system (hardware and software) with power distribution (DC link), cabling (wiring harness for drive train), control unit, and regulation of the entire drive train (diesel generator and traction control, etc.)

- Generator for diesel engine with power electronics

- Axle drives (one drive each for front and rear axle) with power electronics

- Rear PTO (auxiliary drives, PTO) with power electronics

- Peripherals

- Drive for working and steering hydraulics,

- Connection to 12 V vehicle electrical system

- Traction battery (70 kWh).

With the TADUS tractor, I would like to give farmers an effective means of consolidating their energy cycles and making use of the electricity they produce on site, for example with a photovoltaic or a biogas plant installed on the farm. This gives them independence from system conditions that are otherwise difficult or impossible to influence. By choosing Baumüller, we have gained a partner that not only supplies us with a drive train that is perfectly tailored to our development. They also support us with a competent team of developers during the integration of the drive train into the vehicle as a whole. And what’s more: Baumüller recognized the potential of the TADUS tractor right from the start. I am highly impressed by the entrepreneurial vision that Baumüller demonstrates by extending its support to a start-up like TADUS Technologies and meeting it at eye level.

Dr. Thaddäus Baier, co-founder of TADUS Technologies

Advantages over conventional tractors

Up to 70% reduction in energy costs

The efficiency of the battery-run electric drive allows the best possible use of the invested energy. In addition, the cost savings can be attributed to the energy costs: For farmers who have their own power generation (photovoltaic system, biogas, etc.), the price for a kWh of self-produced energy is much lower than with diesel fuel. This means that the cost savings per kWh may be as high as 70% – possibly even higher in the future. Moreover, this figure does not allow for braking energy (recuperation), e.g. during transport work.

Up to 50% longer service life, lower maintenance

The drive train of the TADUS tractor is essentially composed of electric motors along with the necessary power electronics, which are used in motor- or generator-based operation. With electric motors, the number of moving parts is minimal. Fewer moving parts means less wear and tear and thus longer service life with less maintenance. The service life of an electric motor is well over 25,000 h. Taking a very conservative view of all components, one can assume an average total service life of at least 15,000 h. This is up to 50% more than a conventional tractor, whose average service life is 10,000 h.

Up to 100% lower emissions of pollutants and noise

Due to its purely electric operation, the TADUS tractor does not emit any pollutants. In addition, the TADUS tractor is much quieter than conventional tractors, which benefits not only the driver, but also the residents and animals.

Superior usage properties

The TADUS tractor has a power split that is variably controllable in terms of traction drive, hydraulics, and PTO. This means that attachments and hydraulics can be operated independently of the traction drive and optimally adjusted to the specific application. Unlike conventional tractors, this enables the operator to avoid unfavorable operating points of a combustion engine that occur with low to medium power applications (partial load range). As a result, the TADUS tractor saves energy and reduces noise emissions. And this is topped off by the incomparable driving experience of an electric drive with unbeatable controllability.

Use of self-produced energy

As an on-site energy store and consumer, the TADUS tractor can be more than just the missing puzzle piece for an effective overall energy management solution. For farmers who produce their own electricity (photovoltaic system, biogas, etc.), the TADUS tractor is also a means to utilize this energy in the best possible way. This makes agriculture independent of the price of power and diesel fuel.