Baumüller offers energy-efficient direct drive technology for extrusion machines. With this technology you can minimize drive losses, reduce background noise during operation and increase the reliability of the machines. At the same time, the lack of gearing means a smaller size for the machines, which can be designed more compactly.

For special ambient conditions, such as powder processing or production in high humidity regions, water-cooled motors can be used.

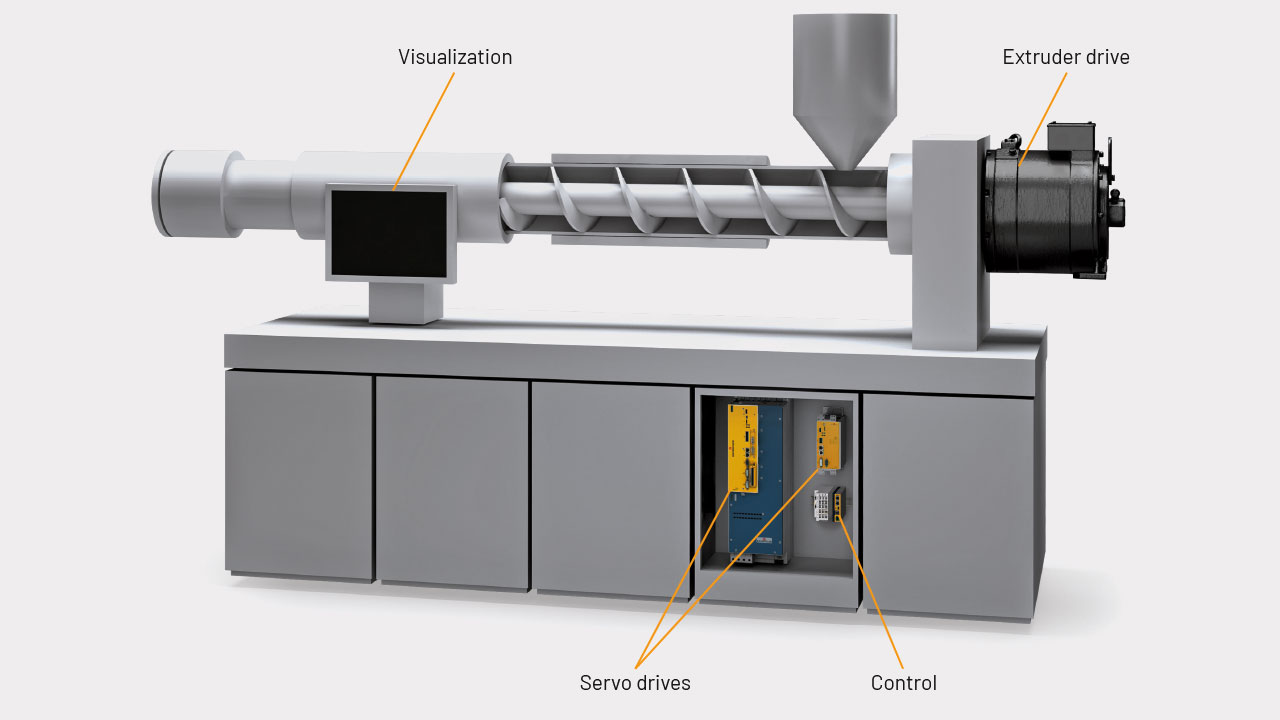

Topology

Benefits of the electric drive and automation

Extruder drive

- High energy efficiency, even within the partial load range

- Coaxial structure for dosing unit enables a compact machine construction even with multi-layer processes

- Intelligent “screw relaxing” controller function: Torque dissipation before switching off the extruder to protect the mechanics

- Sensorless operation of synchronous and asynchronous motor

- Field-oriented control for high torque accuracy

- Optional: precise control for material feed of the extruder screw by servo drive technology

Automation & technology functions

- Extensive libraries included for machine functions, for example, exact and dynamic temperature control of the heating elements for energy saving

- For the networking and control of machines and machine modules

- Enables complex data analyses

- Software for IoT functionalities are implemented

- OPC UA module ensures the interoperability at the machine level

Visualization

- Powerful hardware

- Display sizes from 7” to 15.6”

- Extensive, integrated software package

- Classic or web-based visualization

Are you interested in buying our products?

Write us a message, our sales experts will be happy to advise you.

Baumüller products