Quilting machines are required, for example, to manufacture a comforter. They have the task to unwind panels of fabric and materials, such as cotton, connect them together – that is to quilt– and optionally to rewind. The editor makes any type of quilting pattern possible. By using many needles in combination, a high quilting speed in reached with wide paths. An built in sliding hook is used to reset the gripper on the needle for sideways movements of the transverse drive.

A new calculations of the path to be traveled is carried out for every stitch. The winding process must be done torque and speed controlled. The speed of the panels of fabric and the panel tension force must be constant during the quilting process, despite increasing diameter. During the winding up as the diameter is increasing, the torque of the motor must decrease in the same amount in order to guarantee a uniform material thickness on the reel.

Advantages for your machine concept

Improved design

- Space and cost savings through the use of module systems (smaller control cabinet)

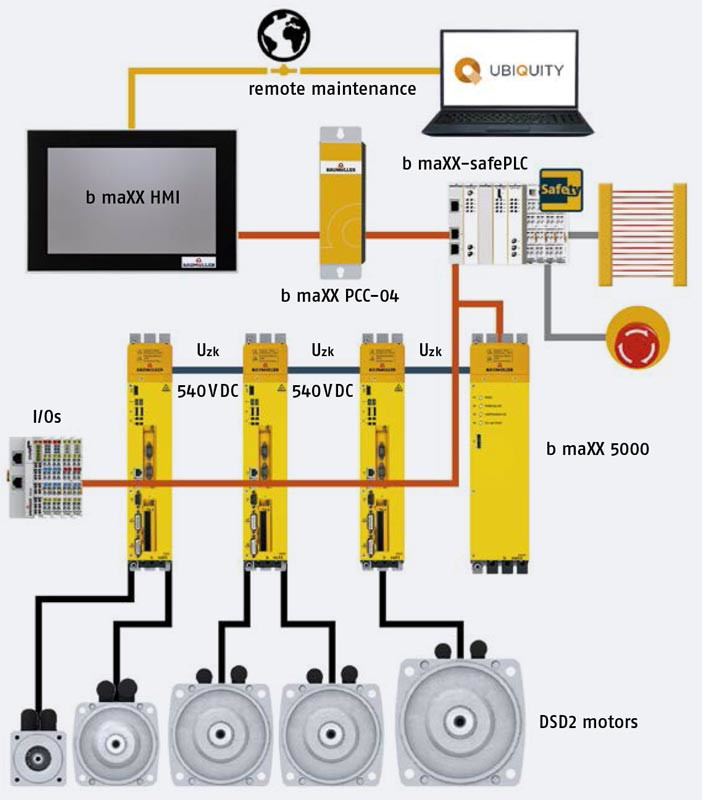

- Complete system comprising drive technology, control technology and software

- Use of coordinated motion for “CNC control” of the machine movements via G-code

Optimized operation

- Continual moving off and dynamic corner movement (splines) reduces the mechanical stress

- Increase of material throughput due to higher speeds

- Increase of machine availability due to web technology

- Avoidance of scrap through safe stop (SS2)

Fast service

- Global access to updates and troubleshooting

- Assessment and graphic representation of shift and production data

- Fast swap of replacement devices

Flexible use

- Faster pattern creation via editor with G-code generation

- G-code generation from graphic files

With Baumüller you get complete solutions from one source!

Your benefits

- Flexibility: incorporate individual specific settings in the process

- Less setup time and thus less extent of work

- Software based: Mechanical can be replaced with electrical

- Fewer trained employees required

- Better product quality

- High product range can be covered

- Field bus can be freely selected

Are you interested in buying our products?

Write us a message, our sales experts will be happy to advise you.