Basics: Torque in motors

Read min.

Torque is the rotational effect of a force on a body. For the torque in motors, however, it is irrelevant at first whether a movement actually takes place. It can also exist at standstill if it is counteracted by an equivalent counteracting force or combination of forces. It can therefore not only accelerate a rotation, but also brake it.

The following glossary entry gives a detailed account of torque with particular emphasis on its importance for the functioning of motors – especially servo motors. The following contents will be examined in detail:

Origin of the term

Another word commonly used for torque is "moment" – a word we initially associate with time. This is not the case for motors. Although the Latin term "momentum" also has temporal meanings, it also covers many other terms. These include:

- motive force, pressure, impact

- circulation and course

- motive, meaning, weight, importance

From this collection of different, but also clearly related meanings, it also becomes evident why the term torque is used for motors. The "motive" force brings something into "circulation" and is the “reason for movement”, "weight" or "pressure", which acts on a vertical lever attached to the axis of rotation.

The more neutral term "moment" is also used, as well as the term "torque", which is commonly used in English in addition to "moment".

Exact definition

The term refers to a physical quantity in Newtonʼs mechanics that describes the rotational effect of a directed force on a body. Together with the rotational speed, the torque defines the transmitted power and can be represented by a vector.

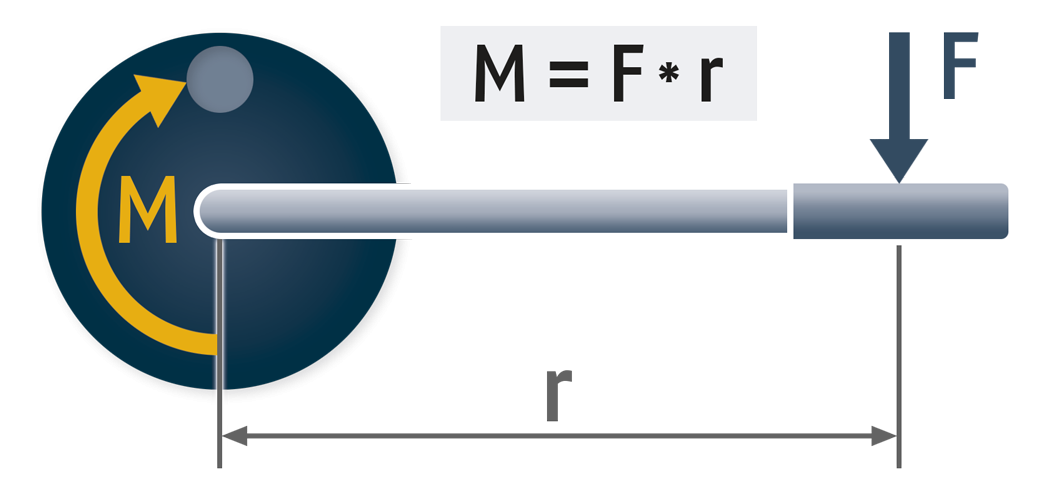

Visual illustration

This can be illustrated as follows: A straight lever is attached to the center of a wheel. If you now turn the wheel using this lever, the torque is the force that must act at a right angle to the lever in order to set the wheel in motion.

Torque is the force that must act at a right angle to the lever in order to set the wheel in motion

Symbols and units

The torque has the formula symbol "M" and is specified in the unit newton-meter (Nm). This is calculated by multiplying the lever length "r" in meters by the vertically acting force "F" in the unit "Newton". A clockwise torque is expressed as a negative quantity, counterclockwise torque as a positive quantity.

Calculations for motors

The simplest formula for calculating torque is the vector product of the length of the lever and the force F applied perpendicularly to it, i.e.: M = r x F.

The problem in practice is that the motion is generally dynamic. Rotational speed and torque are indirectly proportional to each other. This means that a higher rotational speed is associated with a lower torque.

On top of that, forces that counteract the torque must also be taken into account. This includes, for example, the friction of the components. It must also be taken into account that the direction of the acting force is not always perpendicular to the axis of rotation. This is an ideal model that is not so easy to implement in practice.

Practical application in motors

In the actual application in motors, the torque is used as the "drive torque". This term refers to the more specific variant of torque that acts on the input shaft of a transmission and sets motors in motion.

On the one hand, high torque provides more power for the necessary movement – for example, a lot of pressure can be built up in a press. On the other hand, it provides faster responsiveness – meaning that motors can be accelerated rapidly to high speeds at rest if high torque can be maintained.

Torque in electric motors –

importance for servo motors

Torque plays a special role in servo motors. This is especially true when very precise movements have to be realized, such as in the textile industry. If a high torque remains effective even at standstill, motors can be accelerated and decelerated again very rapidly. This allows the precise implementation of highly dynamic movements.

Torque motors –

high electric motor torque

Torque motors are drives that can apply extremely high torque as an electric motor. This applies in particular to all areas of application that only require only low rotational speeds. In the industrial sector, for example, they are used in extruders, shredders, and servo presses. In all these areas, low speeds mean very high force requirements.

Baumüller's torque motors are direct drives that score particularly well in the area of maintenance requirements – for example, compared to drive technology with transmissions or hydraulic systems. Dispensing with a transmission reduces the need for any maintenance, saving both money and time. In addition, it reduces the efforts required for initial assembly. Models can be selected in a force range that extends up to 60,000 Nm.

Practical advantages of direct drives

Direct drives offer numerous further advantages that ultimately increase the efficiency of the production process. These include:

- Significant reduction in energy costs and CO2 emissions

- No additional noise insulation measures required

- Reduction in machine size or operating space

In addition, they improve the overall efficiency of the machine, as no transmissions are necessary when using direct drives. This means that there are neither transmission losses nor pressure losses that would otherwise occur in hydraulic systems, e.g. in a hydraulic press.

Summary – everything at a glance

Torque is the rotational effect of a force on a body. In practice, it plays a major role in the performance of motors. While rotational speed is indirectly proportional to torque, high torque allows the application of high forces, such as those required in extruders, shredders, and servo presses. Fast responsiveness and rapid acceleration to high rotational speeds are also possible when high torque is maintained in motors.

Baumüller's electric motors are also available in the high-torque range, with torques up to 60,000 Nm. If you require detailed information on our products, our customer service will be happy to assist you at any time.

Matthias Beetz

Training Engineer Academy I Baumüller Nürnberg GmbH