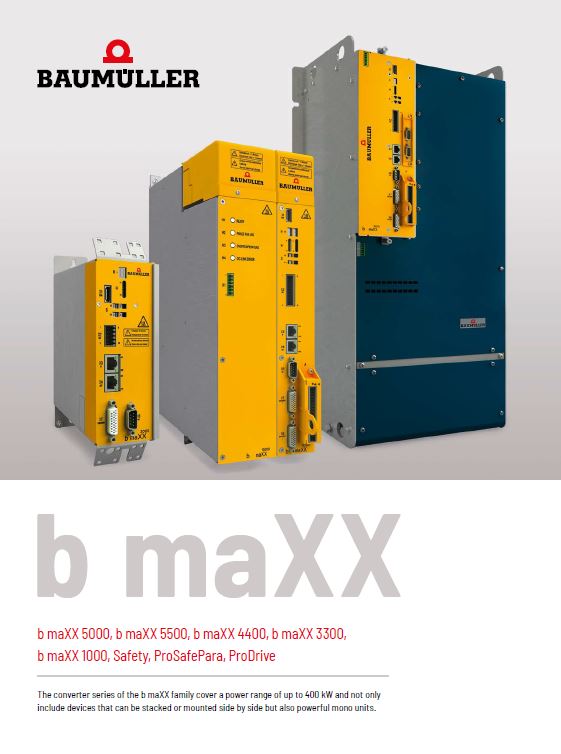

b maXX 5300 - Single and double axis modules for high outputs

The safe, stackable servo controller

The b maXX 5300 sets standards in modularity. The module system impresses with high-performance power units with flexible expandability and connection to an integrated communication concept and a range of cooling methods such as air, water and cold plate. Converters and controllers in the power range from 1.6 to 100 kW allow the implementation of both standardized and complex automation solutions. The requirements for machines and systems for ensuring future reliability, flexible expandability and simple conversion to modified production processes were already taken into account in the development process for the b maXX 5300.

b maXX 5300 features an integrated drive connect system: Individual modules can be easily removed and integrated without having to detach the entire drive system. Benchmark-setting control quality is guaranteed at all times.

The b maXX 5300 axis units are suitable for peak currents of up to a maximum of 420 A and therefore also for significantly higher nominal currents of up to approx. 180 A.

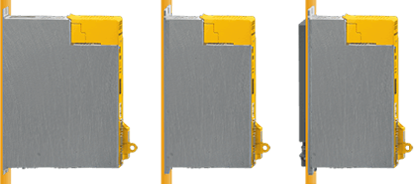

Cooling methods

The axis units of the b maXX 5300 are available with different cooling methods. This allows the user to select the right cooling option depending on the ambient conditions and the requirements of the application.

From left to right: Standard cooling methods air, cold plate and push-through water technology

Fieldbus systems

Flexibility in communication: The axis units of the b maXX 5300 are compatible with common fieldbus systems. This allows the drives to be used flexibly with control units from different manufacturers.

Safety in the drive

The b maXX 5300 offers pluggable safety modules, which are an important component of a comprehensive, drive-integrated safety concept that complies with the requirements of the Machinery Directive. Depending on the application, machine builders can quickly and flexibly adapt the drive to meet the requirements.

Safety:

- Plug-in module, optionally with or without safety functions

- Three different safety modules with scalable functionalities

- All modules with integrated parameter memory for safe and non-safe data

- Safety functions to IEC 61800-5-2

- Power output for motor brake

- Selection of safety functions via local safe I/Os and/or EtherCAT-FSoE

Available safety modules

Safety modules SAF-001, -002, and -003 ensure that the necessary machine safety and future reliability is ensured in line with the latest standards. The b maXX 5300, with the modules’ scalable functionality, optimally fulfills the guidelines laid out by the standards EN ISO 13849 to SIL 3 and EN 62061 to PLe.

The safe functions are selected via safe I/Os available on the safety module or EtherCAT-FSoE.

Baumüller SmartValue: Smart functions create added value

Baumüller SmartValue stands for smart drive-based functions that promise genuine additional benefits for your machines and processes. The b maXX servo controller family includes a wide range of smart functions. The following features are included, for example:

![]() Integrated machine protection: The “synchronous error response” function protects the mechanics of gantry applications if an error occurs at the motor axis.

Integrated machine protection: The “synchronous error response” function protects the mechanics of gantry applications if an error occurs at the motor axis.

![]() Integrated cost efficiency: Save system costs for applications with high performance requirements – the function “encoder angle via fieldbus” allows for the use of low-cost and robust encoder system and reduces the amount of wiring work.

Integrated cost efficiency: Save system costs for applications with high performance requirements – the function “encoder angle via fieldbus” allows for the use of low-cost and robust encoder system and reduces the amount of wiring work.

![]() Integrated productivity: Parameterize a position for your tool in advance – after a power supply failure, the drive executes a corresponding positioning and protects the tool and mechanics.

Integrated productivity: Parameterize a position for your tool in advance – after a power supply failure, the drive executes a corresponding positioning and protects the tool and mechanics.

You will find all the functions at » Baumüller SmartValue

b maXX-softdrivePLC – Intelligence in the drive

With the b maXX-softdrivePLC, Baumüller has rendered separate control hardware unnecessary for certain applications. By combining motion control and PLC functions in the controller, Baumüller has created a decentralized control architecture for programming in accordance with IEC 61131, making it extremely easy to set up distributed intelligence in the machine. Without complicated tools for control programming, control tasks ranging from the simple calculation of digital inputs to highly complex control algorithms can be implemented in a decentralized way in the controller – tasks made easy by the ProDrive parameterization tool.

The b maXX-softdrivePLC runs as part of the firmware in b maXX drives and is suitable for single and double-axis applications.

With the aid of the softdrivePLC, programs are executed in the controller with high synchronicity with the controller clock at cycle times of up to 125 μs, and simple special filters can be programmed, for example. You can also benefit from many other advantages:

- Cost savings due to elimination of control hardware

- Fieldbus communication unnecessary for double axes

- Simple realization of master-slave functionalities

- Cross-axis access to parameters possible

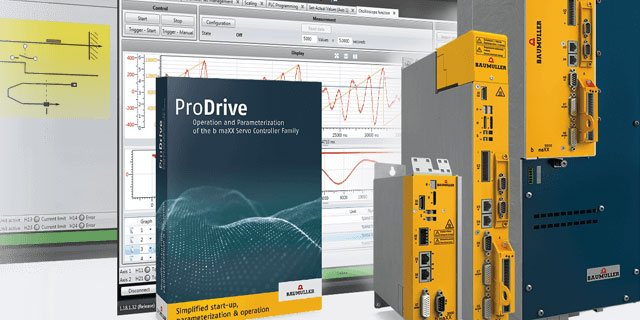

The ProDrive parameterization tool: One tool – many function

The ProDrive parameterization tool gives users of Baumüller servo drives a comprehensive software solution that does much more than a mere commissioning tool. In particular, the extensive options for vibration analysis and the comprehensive self-optimization functions accelerate the time-to-market and allow optimal and efficient device parameterization.

Single-cable solution for power and feedback systems

The Single-cable technology that can be fitted in Baumüller motors saves the user from having to use a feedback cable, which is usually required in addition to the obligatory motor cable. The result is a significant cost savings, as this eliminates the need for additional cables for encoder evaluation.

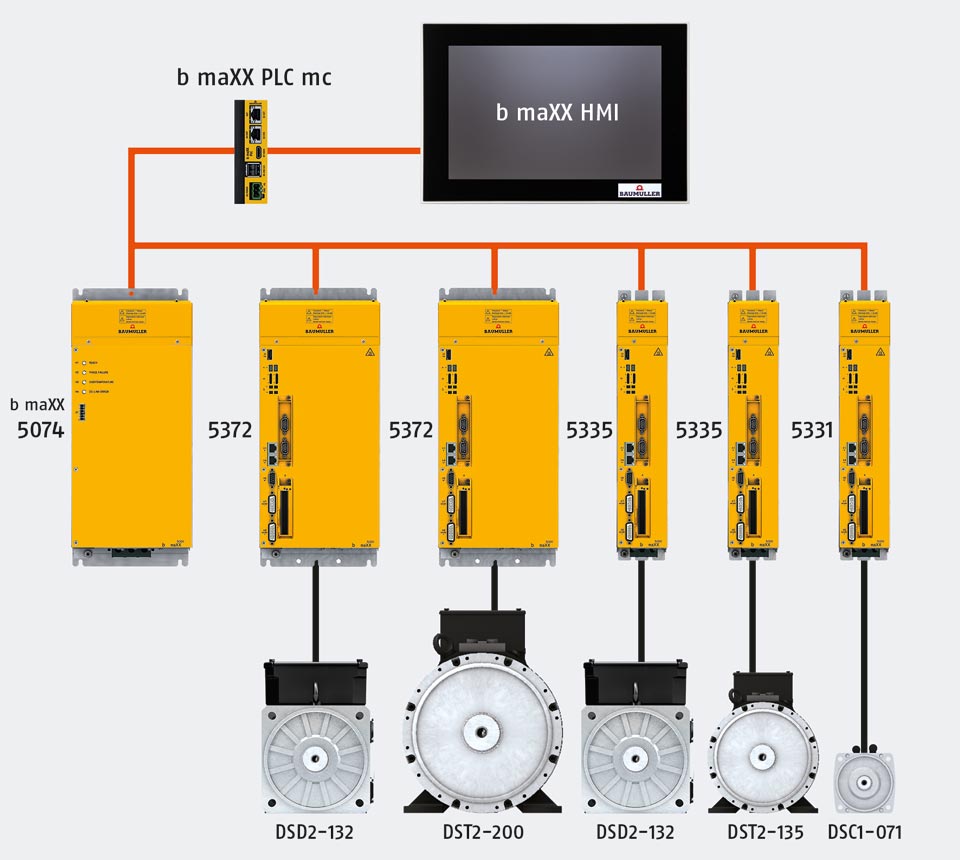

Drive packages for your application

In combination with Baumüller servo motors, you get a drive package that is optimally matched to your application. For hybrid and fully electric machines, we set the important industry trends through concepts developed together with the manufacturer. For example, Baumüller drives in injection molding and blow-molding machines enable consistent quality and ensure optimum process data.

Your benefits — Energy efficiency

System solutions and comprehensive solution expertise are crucial. With smart solutions such as integrated stainless-steel water cooling for motors and converters, we offer complete solutions from a single source.

- Scalable in functional scope and drive power

- System supplier with an extensive product range

- Mechanical friction losses reduced

- Cost savings due to elimination of auxiliary power systems

- Reduction of life cycle costs

Write us a message, our sales experts will be happy to advise you.

Technical data for b maXX 5300 axis units

Supply voltage; 207–528 V ± 0% AC, Supply frequency: 50/60 Hz

Electronic power supply: external 24 V DC

Clock frequency: 4 / 8 kHz

Certification: CE, cUL

Height and depth without mounting brackets.

1) Load cycles acc. to EN 61800

2) Depth of air cooling / depth of coldplate

3) Depth of water cooling

Subject to change without prior notice

You might also be interested in

-

b maXX 5000 - Power supply units

-

b maXX 5100 - Rectifier and regenerative feedback units

-

b maXX accessories for targeted adaptation

-

DC link capacitance module for the b maXX servo controller family

-

Single-cable solution for power and feedback systems

Downloads