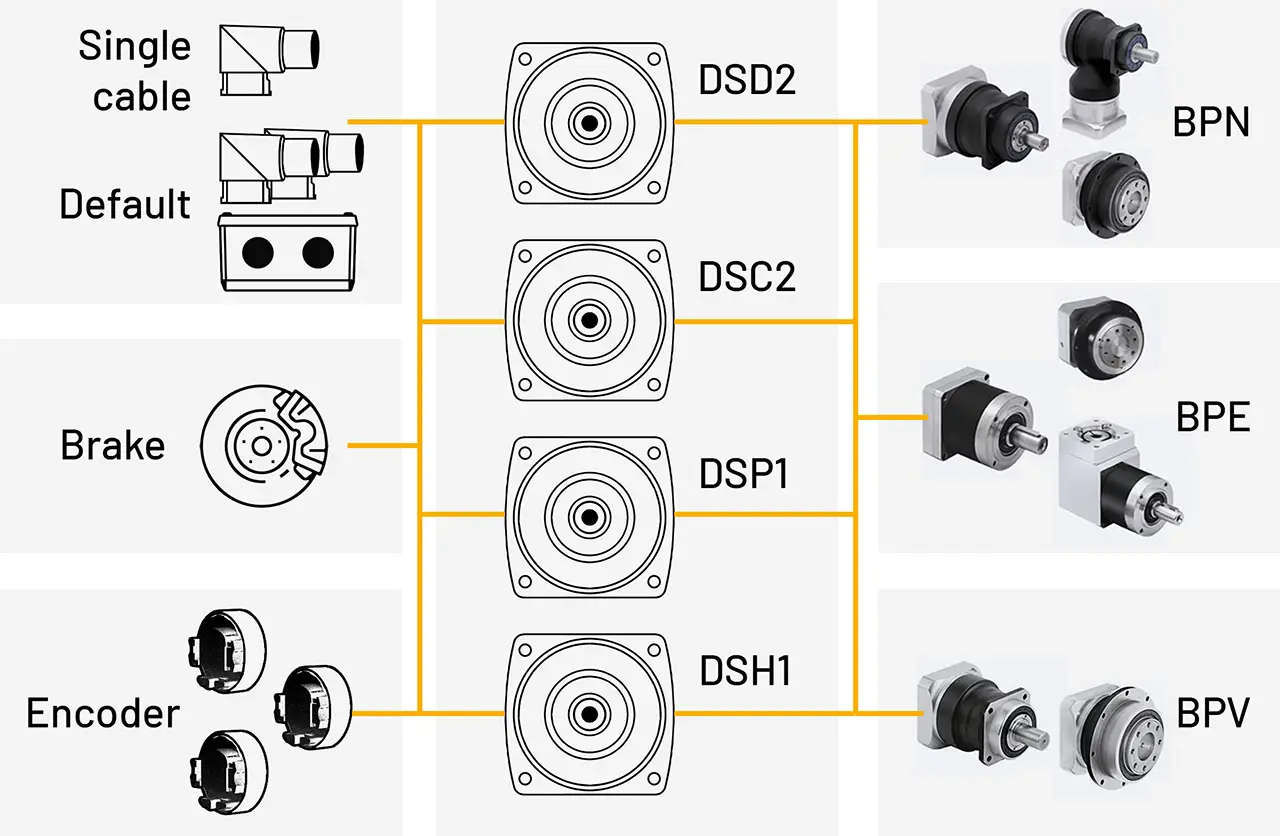

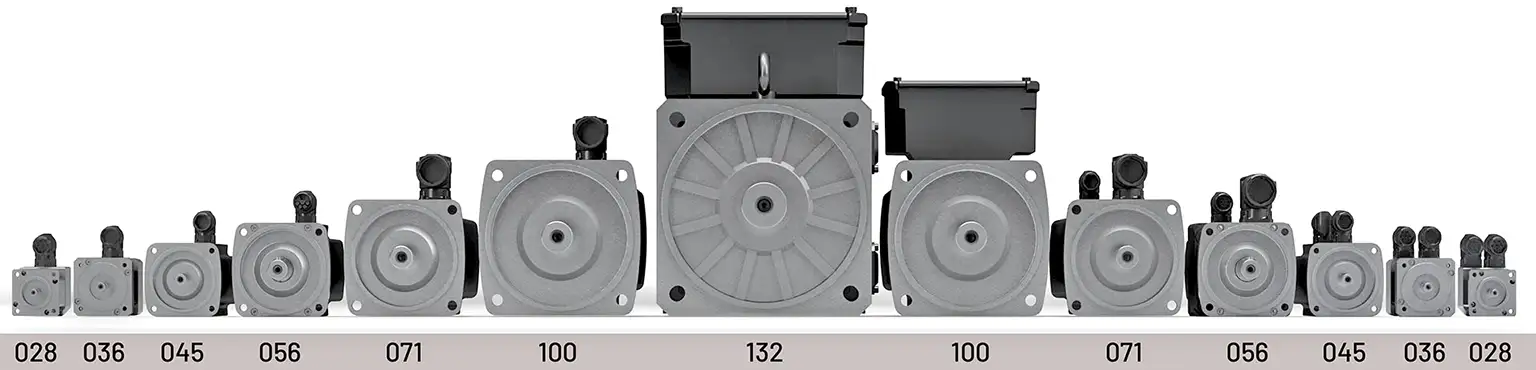

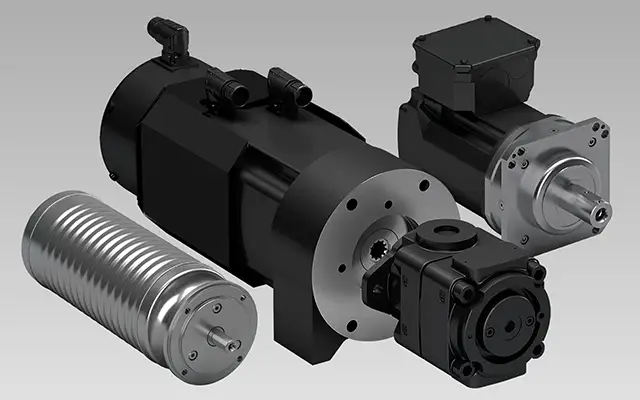

One servo motor – numerous options

With one of the broadest motor offers on the market, Baumüller offers efficient and scalable servo motors in numerous versions and sizes. The servo motors are currently available in seven sizes between 28 and 132 and, depending on their size, achieve power outputs from 0.3 to 150 kW. The nominal speed range begins at 0,6 Nm and extends up to 715 Nm.

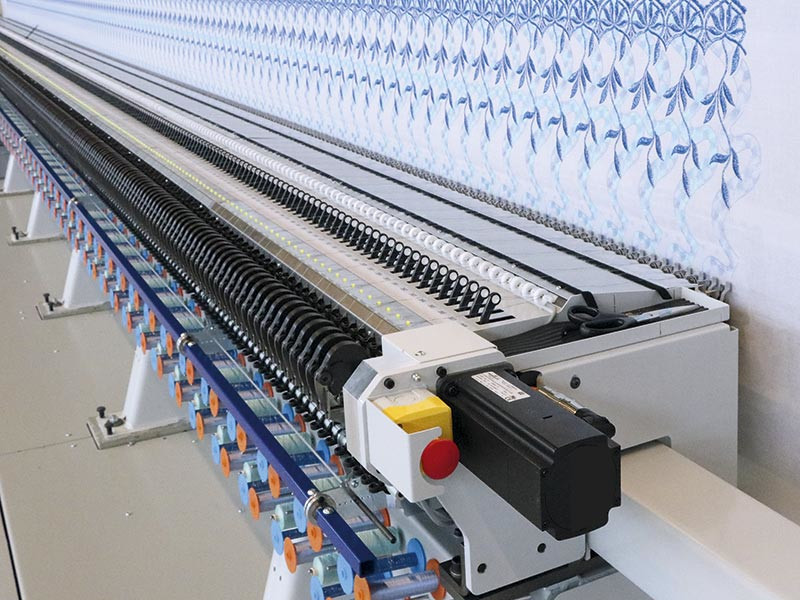

Precisely matched to your machine

The Baumüller modular servo motor range is so flexible

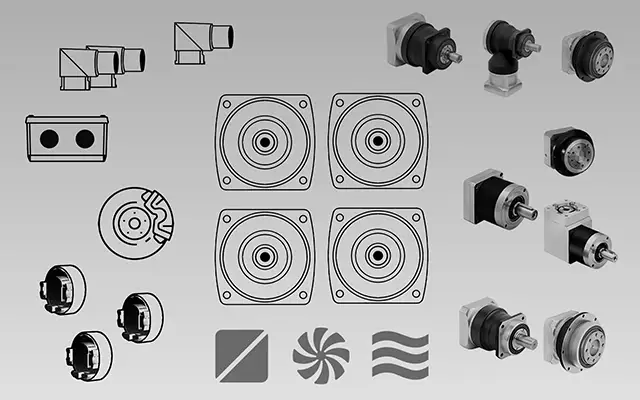

The structure of a servo motor is individual. Application-specific products are created due to all kinds of different cooling options, connections, gear boxes, brakes, and encoder solutions. Baumüller also implements customers’ specific wishes.

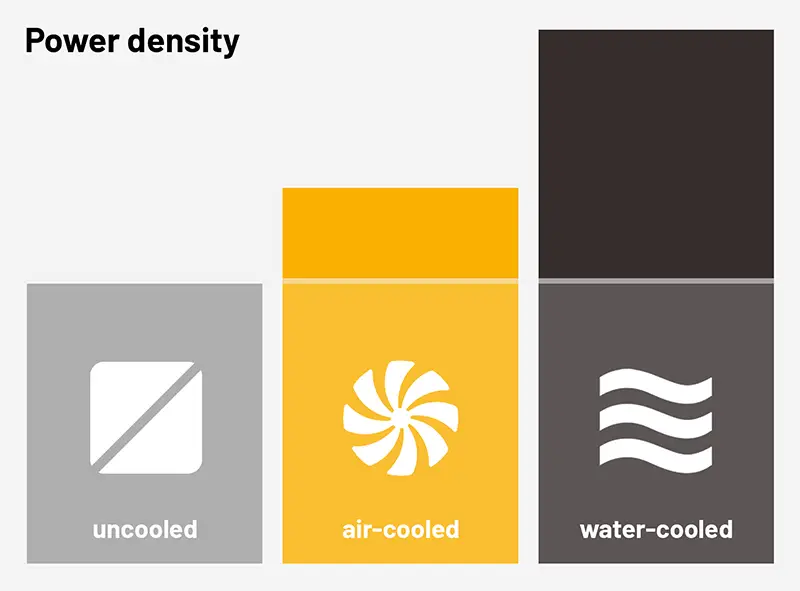

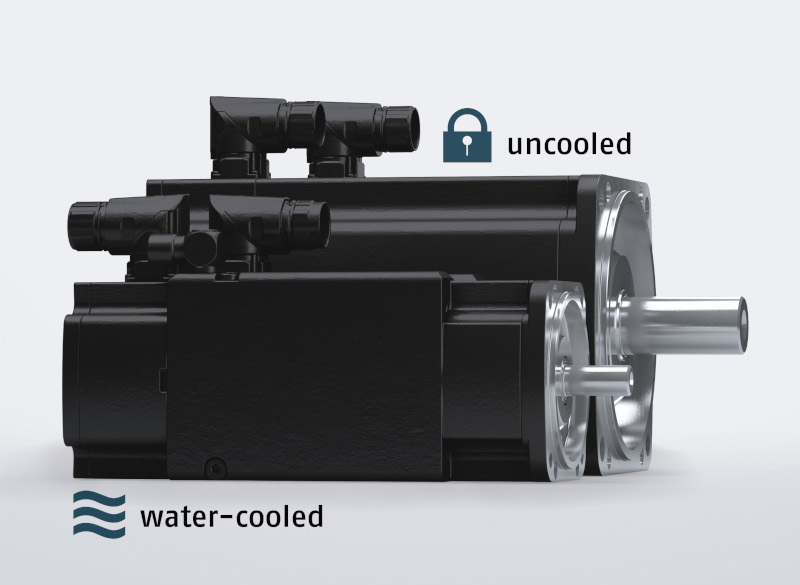

Which cooling options are available?

Our servo motor portfolio includes uncooled, air-cooled, and liquid-cooled servo motors. When it comes to water or oil cooling, Baumüller offers one of the most universal portfolios on the market. For example, water cooling is available as a standard option from size 45 to size 132.

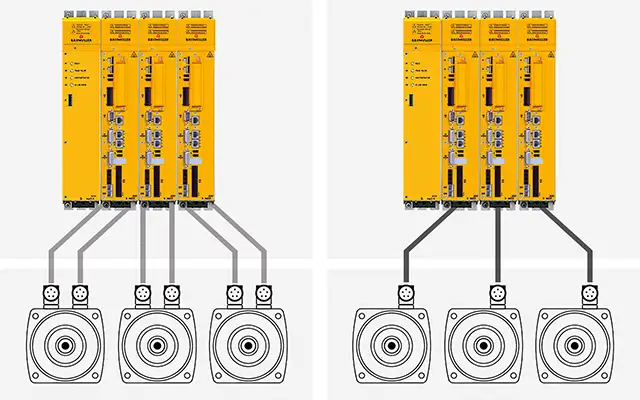

Water-cooled motors have many advantages: The active cooling increases the power density. In addition, close installation of multiple servo motors is easily possible due to the good heat dissipation. This saves space in the machine and is an advantage, particularly in applications with many axes.

Which connection options are available?

Single cable technology, terminal box or two outlets – At Baumüller, these connection options are available as standard features. Single cable technology with Hyperface DSL® is being used in an increasing number of applications. This is convincingly easy to install. The rotatable junction box with SpedTec® closure is fitted within a few sections. Power, encoder information and motor temperature are integrated in the hybrid line. Classic solutions such as the terminal box or two outlets are also still legitimate solutions on the market.

Which encoder solutions are possible?

We work with numerous manufacturers and offer analog, digital and reliable rotary encoder systems. These differ, among other things, regarding their accuracy. Our drive experts advise you on the different variants depending on your requirements. The range extends from resolver to Sick to Heidenhain encoders with their different protocols.

The interaction of our b maXX servo drives with our motors is very precise and can be matched to the respective application. In many cases, we offer our customers cost-optimized system solutions.

Which features characterize our servo motors?

1. Extreme flexibility

Numerous connection options, encoder solutions, brakes, transmissions, and cooling methods make use a unique servo motor manufacturer. Different variants can be configured in the standard version. Our drive experts work with you to search for the best solution – tailored to your application.

2. Customized solutions for the series

You didn’t find what you are looking for in our standard portfolio? Contact us! On request, Baumüller develops application-specific servo motors for serial machines. An adapted design, offset connection technology, shortened overall length – let us know what you need. We check the options and then work with you to search for the solution. Numerous patent applications and satisfied customers speak for themselves.

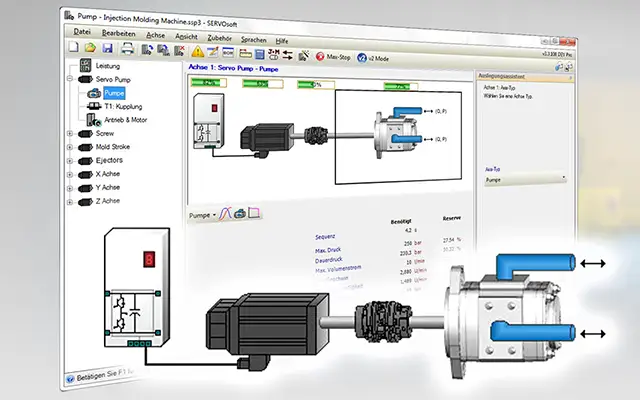

3. Optimal dimensioning

With the sizemaXX drive configurator, you can dimension drives for your respective application conveniently and quickly. The software guides you, step-by-step, through the design process and thus prevents overdimensioning. sizemaXX also identifies potential drive savings. The optimal power density avoids unnecessary energy consumption for the machine operating company. The tool saves you a lot of time, since it calculates all necessary data and outputs the suitable components.

4. Minimize development costs and effort:

You want to use digital tools to save development work and costs? Then you should make use of our simulation service! Our application engineers commission your drive system virtually with a software named ProSimulation especially developed for this purpose. You optimize your machine directly on the digital twin. The experts identify correct design and systematic errors at an early stage. All servo motors and numerous other Baumüller components are included as models in ProSimulation, and therefore enable the drive system and its behavior to be comprehensively mapped in the simulation. Your advantages: Shortened development time and thus fast commissioning.

5. High economy

Servo motors have a high efficiency of over 90 percent. The motors convert most of the electrical energy added into mechanical power. The remaining 10 percent or so of the electrical output is lost in the form of heat. To prevent the motor from overheating, this heat must be dissipated. For this purpose, we offer you servo motors with a sophisticated cooling system. Innovative cooling concepts enable us to build small, compact, and lightweight motors. This conserves valuable raw materials, such as copper for the coils, magnetic material for the rotors, and iron for the motor housing.

6. More than 90 years’ experience

Founded as a repair shop for electric motors, we have been working on flexible motor solutions with passion and commitment for more than 90 years. Tradition and active pioneering spirit can be found in each of our products, particularly in our servo motors. We offer German engineering as standard.

7. Individual advice and application support

We research, develop, and invest in new innovative solutions. Working with customers and other partners, we use our wealth of experience to realize your wishes. Our creative minds in the development, product management and application departments work together closely to track down and implement technological milestones for you.

Our sales experts give you comprehensive advice on our products. They are very familiar with servo motors and know precisely which series suits your machine.

8. Full service provider for drive systems

Our servo motors are optimally matched to all Baumüller components. We offer you everything you need from a single source, from the motor to the servo drive, the control platform and the relevant control cabinet. As a result, we enable you to achieve an open and scalable system architecture with simultaneously high efficiency. Our systems and components can be flexibly combined with different machine controls.

9. Service in more than 40 locations worldwide

Companies from a wide range of different mechanical engineering segments have opted for the Baumüller expertise for many years. In addition to the system and product solutions, with our individually tailored project planning, maintenance, repair, installation, assembly, and relocation services, we cover all the requirements throughout the whole life cycle of machines and systems. You can contact us around the clock – 24/7. We get your drives up and running again in more than 40 locations worldwide.

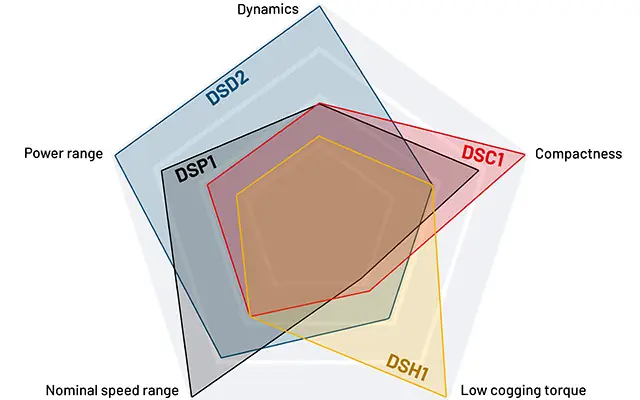

10. Wide servo motor range

We offer you the right solution for every application requirement. We have developed four different series so that this is achieved successfully. These have been in use by numerous customers for many years and differ enormously with respect to their performance data. The DSD2 servo motors are powerful, dynamic and have a very wide range of nominal speeds. On the other hand, the DSC1 servo motors are convincingly compact. A low cogging torque characterizes the DSH1 servo motors, whereas the DSP1 servo motors are particularly high speed.

Write us a message, our sales experts will be happy to advise you.

What is a servo motor?

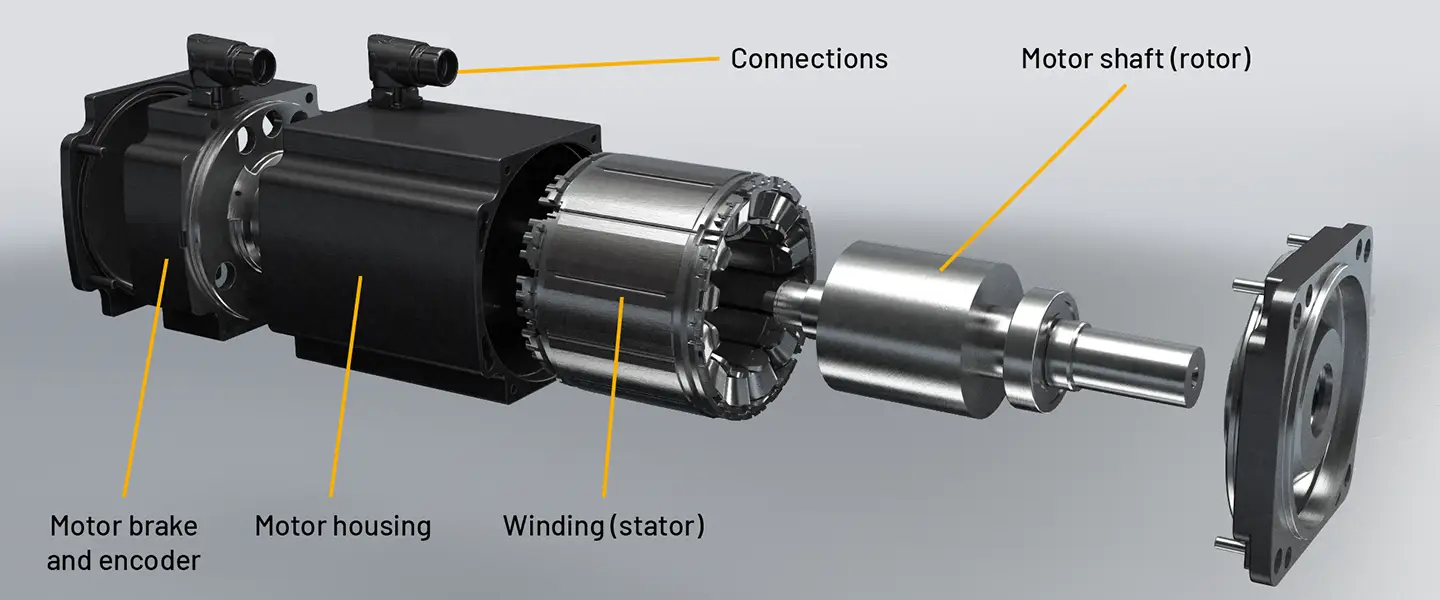

Servo motors are a special type of electric motors. They control the position of the motor shaft and register the speed of the motor. An integrated feedback system determines the angular position and transmits it to the external servo-controller. This then instructs the servo motor how it should move. The result is a closed loop control. The operation can be torque, speed or position-controlled.

Each permanent magnet servo motor basically consists of a motor housing. This contains a stator, a rotor with permanent magnets, and an encoder. Servo motors are individually usable. A major advantage is the motor’s high energy efficiency, which leads to reduced life-cycle costs, and also saves energy and CO2 emissions.

Downloads