Basics: Servo controllers – intelligent intermediaries in automated servo systems

Read min.

The servo controller is an electronic control element for servo motors. It helps to actuate them quickly and precisely by amplifying signals accordingly.

Above all, processes in which motors have to be accelerated to high speeds and decelerated within milliseconds or have to hold predefined speeds can be implemented reliably. In addition, the servo controller ensures that the motor can hold a certain or move to a predefined position or, depending on the preselected mode, can maintain a predefined torque.

On disambiguation:

This is unfortunately frequently imprecise. The term servo converter can be used as a synonym. Some manufacturers also use the term servo amplifier. However, the term servo controller is more precise, since it describes the present-day functional diversity of the component, which is not merely limited to converting and amplifying signals significantly better.

Definition – What is a servo controller?

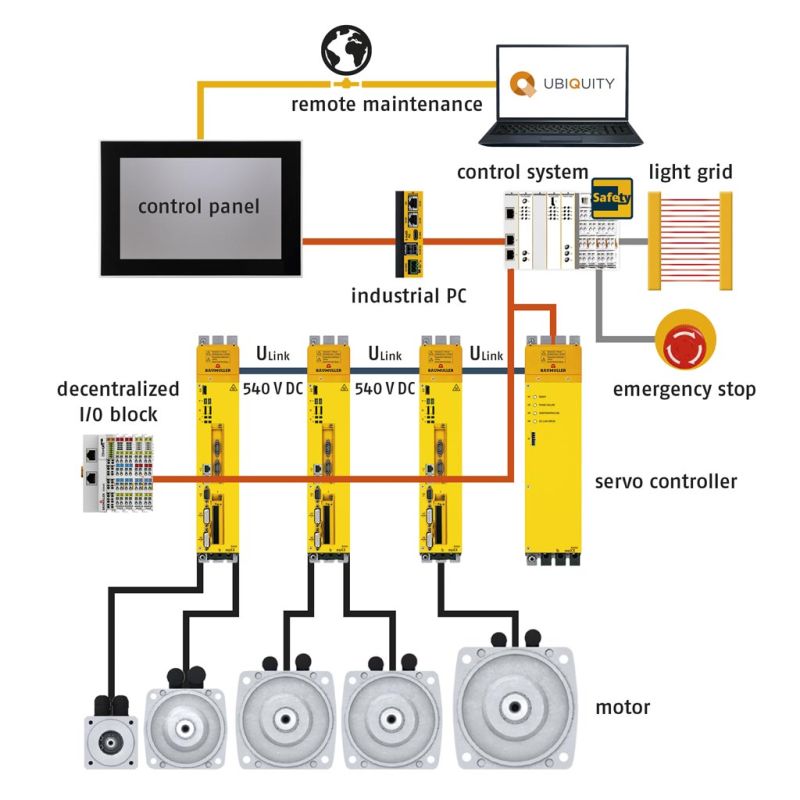

The servo controller is the link between the servo motor and a high-level control (PLC or programmable logic controller). It adapts the original signal and forwards it to the motor. The controller therefore enables extremely precise control of position, speed and torque. As a result, the servo motor can actuate and hold specific positions with maximum precision and speed. The torque is retained, which allows very fast changing from standstill and between different speeds.

Alternative terminology

- Servo converter

- Servo amplifier

They mean the same thing. Strictly speaking, however, the terms servo converter and servo amplifier are obsolete, since the scope of functions has expanded massively thanks to technical progress. Servo controller is therefore the more precise and contemporary name, which is why it is used for our Baumüller b-maXX-servo controller family.

Whole system of a servo drive and the role of the converter within the system.

Areas of use

Precise and dynamic control of servo motors is now playing an increasingly decisive role in many industries and areas of use, which is why only a small selection of examples can be given here:

-

paper and printing technology

- packaging systems

- conveying technology

- plastics production

- medical technology

- robotics

- e-mobility

One particularly large area of use is the textile industry. The precise, uniform and fast production – for example, of seams or stitching – requires decidedly precise control.

The situation is also similar in metalworking: Drilling, bending, different surface treatments and cutting with plasma or laser technology require an equally high level of precision and dynamic control options, which can be implemented with digital parameterization and automation.

The advantages of servo technology in comparison to conventional drives

The unit consisting of digital control, servo motor and interconnected servo controller offers numerous advantages. These particularly come into play in automation and robotics, which is why the technology is increasingly establishing itself.

Horizontal stackability

With horizontally stackable servo controllers from Baumüller, several servo motors can be easily installed side-by-side, which can then also work asynchronously. In this way, very individual systems can be implemented. Subsequent adjustments and integration in existing concepts can therefore be realized in a particularly flexible way.

Precision

Speeds and torque can be determined precisely with the servo controller. This means that predefined targets can be actuated and held. The speed can also be increased and reduced to adjust to the goal in fractions of seconds.

Safety

The servo controller also offers the option of switching off electric motors from a central place, which increases safety. Unlike the individual switching off of individual motors, they can be stopped directly and simultaneously in an emergency. The Baumüller servo controllers of the b-maXX-5000 family offer such an option.

Efficiency and cost savings

High performance is coupled with low energy costs. While the operating costs are optimized, the initial outlay is kept low. With its Connect Drive system, Baumüller offers the option of installing and commissioning the servo drives particularly economically. Maintenance work is also low and the life is long.

Intelligence in the controller

Functions that were previously found in a central control can now be implemented in the drive itself. On the one hand, this means connectivity via bus systems, and on the other automation. The servo controller can also be used to generate and process data in the drive system. These can then in turn be used to carry out process optimization.

Detailed information on intelligent drive technology from Baumüller is available here

Advantages for individual process operations using the example of the textile industry

A prime example of the use of servo systems is the industrial production of textile products. With the appropriate drive, for example, complex multi-needle lockstitch machines can reach extremely high sewing or stitching speeds, which lead to significantly increased productivity.

Since such processes require a very high degree of precision, the servo motors used must carry out the finest possible movements, whose response time is within the microsecond range. The requirements of this type of protection are met by Baumüller servo motors with appropriate controllers.

Summary – everything at a glance

As the intermediary between the control and motor or motors, the servo controller offers a flexible and dynamic setting option. The areas of use include virtually all production industries in which particularly high mechanical precision and flexibility are required. Changes to the overall system and adjustments to safety requirements can also be implemented in retrospect without having to change the existing setup.

You are welcome to contact us in person at any time for further information on our servo controllers.

Matthias Beetz

Training Engineer Academy I Baumüller Nürnberg GmbH