Innovative drive solutions for servo presses

Compared with conventional hydraulic or mechanical presses, servo eccentric presses provide considerable advantages, such as increased productivity and higher product quality. Furthermore, they offer the user enormous additional flexibility.

Consisting of both control and drive technology, the Baumüller system solution gives you the advantages of servo presses while at the same time providing an instantly usable and flexible solution for your machine. We support you with the engineering and will implement the drive, machine control and software for you, completely and entirely according to your wishes. Baumüller also offers optional long-term life cycle management for your presse that is individually tailored to your needs and those of your customers. On request, we will also support you with the installation and commissioning of your system anywhere in the world.

- Dimensioning

- Simulation

- Commissioning

- High-torque motors

- System inverters

- Power modules

- PLC control

- Control cabinets

- Movement profiles

- Load distribution / synchronization

- Control interface

- Setup functions

- HMI

With its components and services, Baumüller offers the largest scope of solutions for servo press drive systems. As a drive and automation manufacturer, we have many years of experience in equipping servo presses and, as a full-range supplier, we are at your side from the planning through to commissioning and service.

Benefits of a servo press compared to a conventional hydraulic and mechanical press

Compared to conventional presses, servo presses are a superior solution in terms of productivity, product quality and flexibility. With high-performance direct drives and the compatible control unit, the processes of servo presses can be optimized with regard to cycle time, tool wear and tear, energy use and environmental compatibility.

Precisely tailored to our customers: From the motor through to the complete drive system

Baumüller offers the exact service you require - from individual motors and components to comprehensive drive systems with control technology. We always support your precise needs. Baumüller is a partner for machine manufacturers and a supplier of complete systems.

from the motor to the overall system

< 100 t – 3000 t

Eccentric presses

for system optimization

Whether refurbishment or modernization – Baumüller provides the perfect drive solution for your servo eccentric press.

Retrofit of a traditional mechanical press into a servo press

I agree that external content may be displayed to me,

which means that personal data may be transmitted to third-party platforms.

Read more about this in our privacy policy.

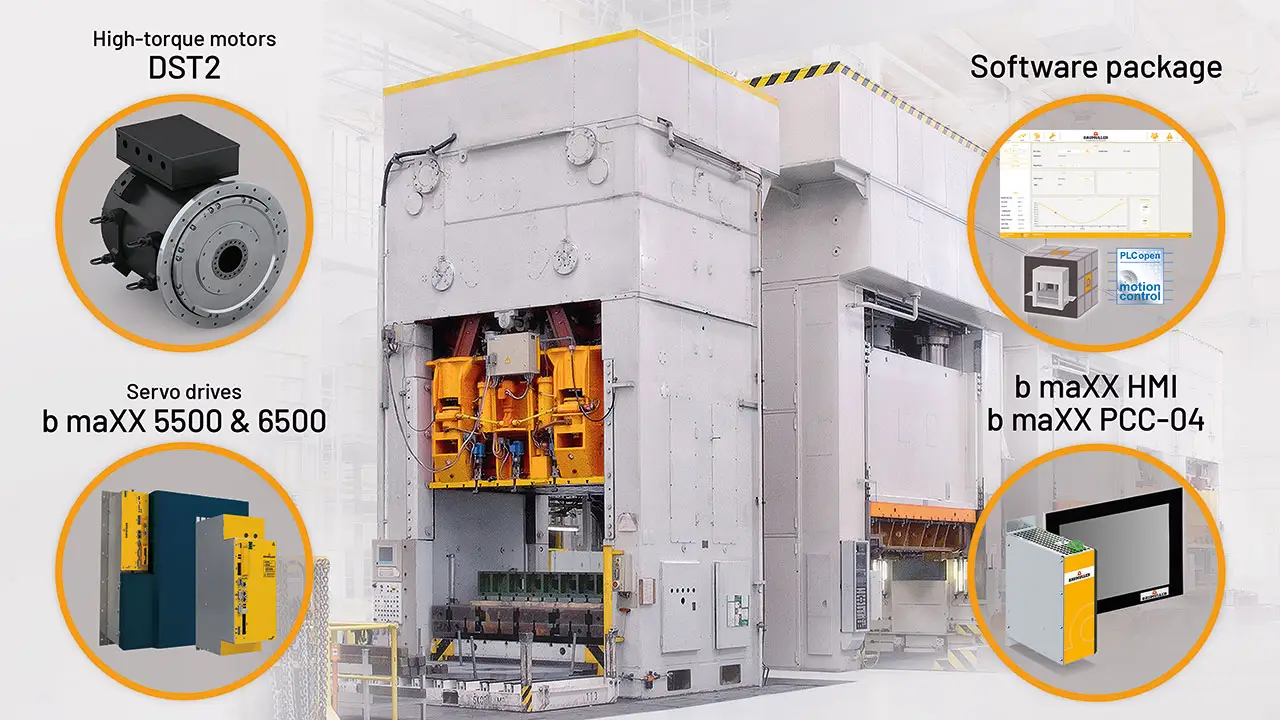

Complete drive system solution – scalable technology from Baumüller

Our system solution includes the complete main drive system with high-torque motors, servo converters and system inverters, including control cabinet construction as well as the control technology with hardware and an extensive complete software package specially for servo presses. The drive unit is configured individually depending on the required power.

The drive system is linked to a higher-level control system via a predefined interface and is vendor-neutral.

Our DST2-series high-torque motors achieve very high maximum torques, in order to provide the necessary power for the forming process. The motors can be perfectly adapted to the press’s requirements thanks to different shaft and flange options. We also enable the press power to be divided between multiple motors connected via a master-slave coupling.

With the b maXX 5000 converter family, Baumüller offers suitable servo drives for high power classes. The servo drives impress with their compact installation dimensions and offer a broad and scalable selection of optional safety functions. The devices also have the option of energy recovery. The connected system load can be reduced by intelligent energy management and the use of capacitors as energy stores, which in turn saves energy and costs.

Overall systems consisting of high-torque motors, peak-load converters, control unit and special press visualization enable efficient and productive servo presses for different areas of application

Overall systems consisting of high-torque motors, peak-load converters, control unit and special press visualization enable efficient and productive servo presses for different areas of application

Everything from one source: A complete package, tailored to your needs

In order to provide the high press forces required for the servo eccentric presses, depending on the gear ratio, motors with very high maximum torques are needed. The Baumüller DST2 series high-torque motors are therefore predestined for this application. Due to their low inertia, they also meet the dynamic requirements of the application.

Baumüller can also supply the right drive system for large servo presses. Thanks to the modular b maXX 5500 drive electronics, with the help of multiple-winding systems, even the large motors of the DST2 series with over 1,000 kW power can be used and combined to form multi-motor solutions.

The system is completed by the use of b maXX 5100 rectifier and regenerative feedback units and an energy store designed to precisely match the customer’s requirements.

Due to the modular use of components, this drive system kit enables us to realize a very wide range of presses with minimum variance in the drive system. This very much simplifies the order process as well as warehousing/replacement part stocks for the customer.

Standard control cabinets through to completely wired special control cabinet

For many years, we have been implementing custom solutions for renowned machine and plant manufacturers - from the standard control cabinet through to the completely wired special control cabinet. You receive everything from us, a single source that can therefore deal optimally with your needs and wishes:

Planning – design – sheet metal production – serial production -

assembly - installation

Drive design with ProSimulation

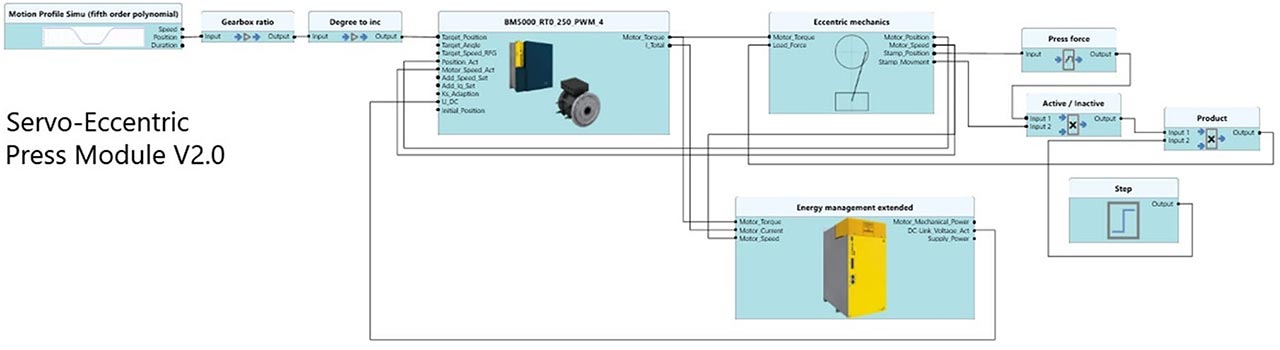

The digital twin offers many advantages, especially during the engineering phase: The development time is shortened, and the machine can therefore be placed on the market as quickly as possible and functionally reliable. With ProSimulation, Baumüller offers simulation models of its drive components. In addition, Baumüller undertakes the complete design of the design technology for its drive technology.

The simulation model of the servo eccentric press in ProSimulation enables efficient drive design and minimum connected system load of the machine

The simulation model of the servo eccentric press in ProSimulation enables efficient drive design and minimum connected system load of the machine

This offers numerous advantages, particularly for complex applications such as servo eccentric presses: It enables the selection of an efficient and resource-saving drive package. For example, the whole drive topology can be mapped in the software. This consists of the nonlinear transfer ratio of the eccentric mechanics, gearing, high-torque motors, servo drive technology and energy store in conjunction with dynamic movement and force profiles. The simulation creates transparency in the power and energy profiles and describes charging and discharging processes in detail. This enables efficient dimensioning of the energy store and therefore the connected system load can be reduced. This saves resources, relieves the power supply system considerably and reduces the machine’s footprint.

Software solutions for servo presses

You save time and money with our complete software package, since all the basic functions of a servo press are available to you. They include, for example, the creation of movement profiles, energy management and a predefined interface with a higher-level process control. A standardized interface can be used to quickly and easily expand to include a customer-specific special function.

On the control level, Baumüller offers the powerful b maXX PCC-04 box PC, a scalable, versatilely usable platform which offers a large number of interfaces, is expandable, and therefore enables flexible machine architecture.

Our solution

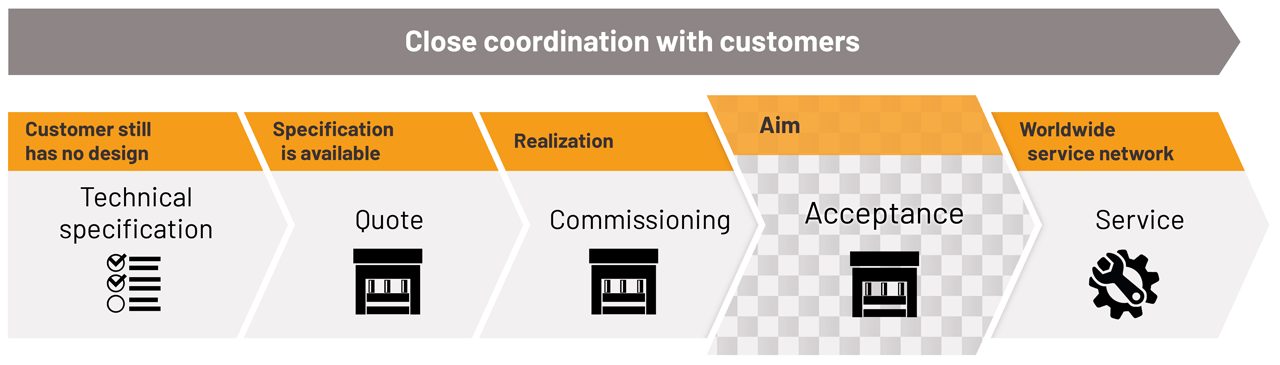

Your path to a qualified quote

You would like a no-obligation consultation or quote? Then contact our experts.

We discuss the relevant technical details with you and together we define the requirements. Only then do we undertake the qualified design of the complete drive system. After checking the specifications, you receive a qualified quote from us.

Baumüller is your partner for the production-ready design and optimization of your drive system. As a non-group-affiliated, mid-sized company, we are able to respond to the wishes of your customers quickly and efficiently with innovative drive solutions. This makes us the perfect partner for challenging projects and future technologies.

Write us a message, our sales experts will be happy to advise you.

Our components for servo presses:

Downloads

Servo presses

Engineering | Hardware | Software