Basics: The servo motor – how it works, cooling and areas of application

Read min.

The servo motor is an electric motor, which enables continuous determination of precise positions, speeds and torque via control electronics (servo controller). A software interface with the control electronics also allows precise parameterization and programming for actuation of the motor, which provides a high degree of dynamism and individuality.

In particular, additive processes in plastics production as well as automation and robotics solutions can be implemented efficiently and enable maximum precision for production processes.

Origin of the term

The term servo motor must be viewed historically. “Servus” is Latin for servant or slave. The name comes from earlier areas of use in which the motors were used as support drives (auxiliary drives). Due to the rapid continued development of components, e.g. semiconductor technology, they are now also increasingly being used as main drives, when a high degree of dynamism and precision is required.

Definition now: What is a servo motor?

By virtue of the way in which they work, servo motors have a special feature in that torque, speed and position can be controlled precisely, and therefore very fine and dynamic movements are made possible. It is always connected to a servo controller, which converts the signals of a control unit, which nowadays is mostly digital, and therefore allows precise programming. In the manufacturing industry, servo motors are used in all types of automation solutions, e.g. for printing machine roll control, additive production methods in plastics technology or in any form of robotics.

How a servo motor works

Modern servo motors are actuated by a servo controller – both together form the servo drive. With this combination, the motor can be operated with very dynamic movements, high effective torque and high power density. Due to the way it works, it is also particularly energy efficient and can achieve high nominal power with relatively small deviation. Costs are therefore saved on multiple levels, which are reflected in better economic efficiency of servo-assisted drive systems.

The greatest strength of the servo motor and the way it works, however, does not emerge until it interacts with the servo controller. Together, software-supported programming is possible, which ensures outstanding precision. Predefined torque, position and speed can be controlled with maximum precision and dynamically adapted to the required movement. Very complex machine processes can therefore be implemented.

Proper cooling

Since servo motors are generally subjected to high loads, effective cooling is indispensable in many cases. This can be implemented in different ways:

- Air

- Oil

- Water

Air cooling can be an option, but has the disadvantage of taking up a relatively large amount of space and is maintenance-intensive, due to the regular cleaning required. Failure to clean leads to reduced cooling capacity and the machine can fail.

A water-cooled servo motor solution can be implemented with significantly less space and also requires less maintenance. In addition, a compact, side-by-side arrangement of multiple servos is possible, without heating each other with the waste heat produced. The same applies to cooling with oil, although here the cooling capacity is somewhat lower.

Summarizing, water cooling is the ideal solution, especially for sophisticated areas of use. Compared to uncooled versions, Baumüller’s water-cooled servo motors can be operated with significantly more performance and the same dimensions.

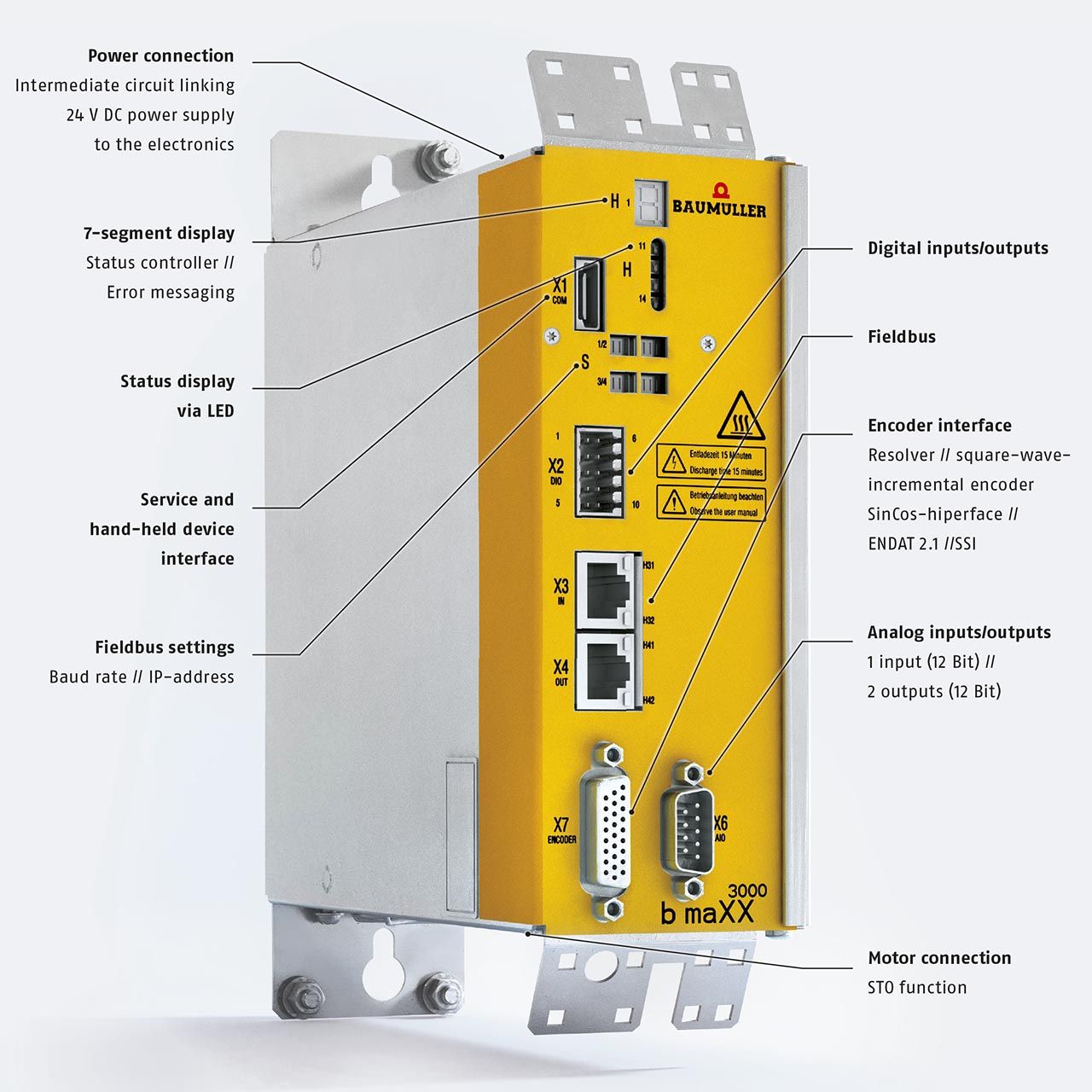

How is a servo motor actuated?

A so-called servo controller is used as the intermediary between the control unit and the motor. Due to the way in which it functions, the component is also known as a servo converter or servo amplifier and controls the torque, speed and position of the motor with high precision. It forms the link between the software user interface and the motor and converts the signals accordingly.

The servo motor and the advantages of how it works

Above all, the servo drive offers a high level of precision and can actuate and hold defined positions , without losing torque. This enables very fast accelerations and decelerations at certain speeds. The machines or robots driven by the servo motor can therefore implement movements very dynamically and are ideally suitable for complex work.

Servo motors provide good value for many due to comparatively low initial costs, low maintenance costs and a long life. They can therefore also be easily integrated in existing systems.

Function in many areas of use

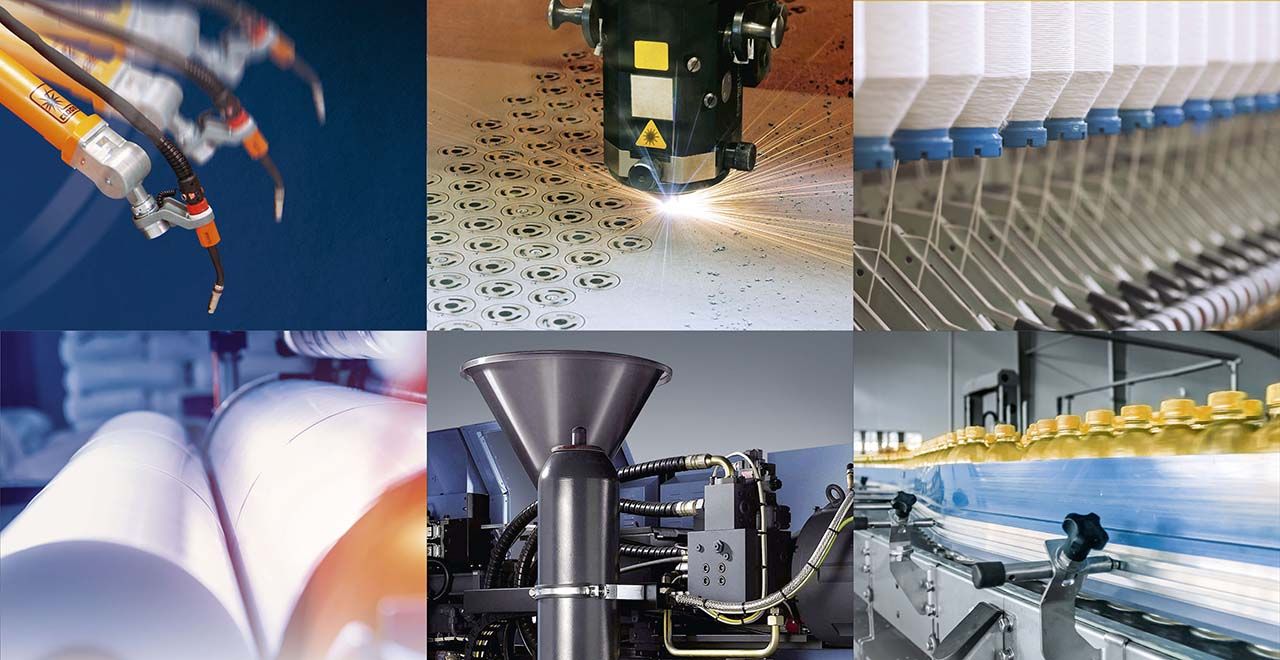

The areas of use cover almost all areas of the manufacturing industry. In particular:

- plastics industry

- packaging machines

- textile processing

- printing technology

- e-mobility

- shipbuilding

- energy technology

- metalworking

- pharmaceutical industry

Plastics industry

Plastics processing can profit particularly well from the way in which servo motors work. They are used not only for injection casting but are now also extensively established in additive processes. Especially in the production of plastic parts in all areas of mobility, maximum precision is required, which can be implemented optimally with the right servo system.

Textile processing

Weaving and knitting, and many other types of textile processing require precise and dynamic machines to achieve a good end result. The way in which a servo drive works is also ideal for this, since not only the necessary precision is achieved, but also the characteristic low maintenance enables more economic processes.

Printing technology

The drive systems for paper and printing machines also benefit highly from the servo motor. Individually tailored solutions can be implemented here for the diverse requirements of the printing industry.

Summary – everything at a glance

The way in which the servo motor works offers a great deal of flexibility, precision and reliability with high cost efficiency. It can actuate and hold positions, torque and speeds precisely and in fractions of a second. This enables complex machine actions, which can also implement difficult production processes and are therefore particularly suitable for robotics and automation solutions.

Baumüller servo motors optimize the already efficient function of this type of drive. In combination with the appropriate servo controller, complex, dynamic system solutions, individually adapted to the circumstances can be realized.

You are welcome to contact us in person at any time for further information on the servo motor structure and individual implementation in existing systems.

Matthias Beetz

Training Engineer Academy I Baumüller Nürnberg GmbH