b maXX 6500 – compact mono units for large outputs up to 400 kW

Reduced footprint

Installation space decimated — Power density multiplied The new b maXX 6500 (left) is offered with an extended power range up to 400 kW and requires approx. 71% less space than the market average in size 4.

Installation space decimated — Power density multiplied The new b maXX 6500 (left) is offered with an extended power range up to 400 kW and requires approx. 71% less space than the market average in size 4.

The scalable power modules of the mono units are offered with an extended power range up to 400 kW. Applications with a power requirement above 400 kW can also continue to be realized by connecting multiple converters in series. With fuse ratings optimized still further, the new devices are even more precisely configurable for the respective application.

Highly reduced installation space

For the b maXX 6500 mono units, the dimensions could be reduced significantly and the power density greatly increased.

In the case of the size 4 with a power range up to 75 kW, for example, this means a saving of 71% compared with the market average. The new mono devices therefore require less space in the control cabinet and can be installed in the most confined space even more easily.

Maximum power

The peak power for the new b maXX 6500 mono devices was increased considerably. Compared to the b maXX 5500 series, for e.g. servo, the size 4 devices achieve a peak current that is 20 percent higher. This allows the use of a smaller installation size in many applications, thus further optimizing space requirements in the control cabinet as well as costs. Alongside the physical machine footprint, the material savings in the servo drives and control cabinets also mean a reduction in the ecological footprint and more sustainability.

Application-optimized through scalability

From the basic device to the fully equipped: With a large number of configuration levels, the new generation of the b maXX 6000 family can be adapted even better to the requirements of the respective applicationThe b maXX 6000 devices have maximum scalability due to numerous hardware and software options and can therefore be even better adapted to the application requirements.

From the basic device to the fully equipped: With a large number of configuration levels, the new generation of the b maXX 6000 family can be adapted even better to the requirements of the respective applicationThe b maXX 6000 devices have maximum scalability due to numerous hardware and software options and can therefore be even better adapted to the application requirements.

Different encoders, hardware and safety options are available to choose from. For example, in the case of encoders, you can choose between resolvers, optical and pure digital encoders for all standard interfaces. For the hardware, the signal bus, service option, digital and analog I/Os, as well as brake connection can be selected, among other things. With regard to safety, different variations are available, from the simple hardware controlled STO (Safe Torque-Off) through to higher safety functions actuated via FSoE (FailSafe over EtherCAT), all of which comply with the highest safety level.

Thanks to this scalability, a large number of configuration levels are available, from the basic device through to full specs. The machine manufacturer can thus put together the controller and power module equipment to precisely fit their application.

b maXX 6500 – compact mono units for large outputs

I agree that external content may be displayed to me,

which means that personal data may be transmitted to third-party platforms.

Read more about this in our privacy policy.

New series – new functions

The new b maXX 6000 series impresses with its numerous new functions, which have been specially developed for sophisticated applications. The new controllers are faster and more reliable than ever before. Despite the expanded functional scope, the firmware is fully compatible with the preceding b maXX 5000 family – a changeover is therefore possible without new programming or parameterization.

Here are some of the innovations at a glance:

Safety for high-performance applications

- Even faster response (1ms) to safety-related events

- Transfer of the safe position via FSoE to the safety control as the basis for 3D space monitoring

- Digital encoders can be used as safety encoders

- Safety possible via load-side encoders

Prepared for Drive-PLC

- Real time data processing in the drive

- Drive can be used as a data hub for connection of direct and indirect sensors

- IoT-ready thanks to OPC-UA and MQTT

Fully compatible firmware

- Simple change from b maXX 5000 to 6000: Parameter data sets can be transferred.

- Drive-based functions and softdrivePLC projects can be further used with no changes required

- Only a minimal amount of work necessary for adjusting the parameterization for FSoE

b maXX-softdrivePLC - Intelligence in the drive

With the new b maXX-softdrivePLC, Baumüller has made separate control hardware unnecessary for certain applications. By combining motion control and PLC functions in the controller, Baumüller has created a decentralized control architecture for programming in accordance with IEC 61131, making it extremely easy to set up distributed intelligence in the machine.

Without complicated tools for control programming, control tasks ranging from the simple calculation of digital inputs to highly complex control algorithms can be implemented in a decentralized way in the controller – tasks made easy by the ProDrive parameterization tool. The b maXX-softdrivePLC runs as part of the firmware in the Baumüller drive concepts b maXX 6000, b maXX 5000 and b maXX 3300 and is suitable for single and double-axis applications.

b maXX-drivePLC: One of the fastest in-drive PLCs worldwide

With a cycle time of 100 μs for 1000 lines of STL, the b maxx-drivePLC is suitable for both extensive control and demanding motion control tasks. This means that by using our PLC, the control PLC can be relieved, downsized or even completely replaced. The clean decoupling of motion control applications from the machine program also creates a new level of transparency and clarity in the application.

Programming via ProDrive

By using softdrivePLC, you no longer need complicated tools for control programming. Control tasks can easily be implemented in a decentralized way in the controller via the ProDrive parameterization tool – from simple calculation to highly complex control algorithms.

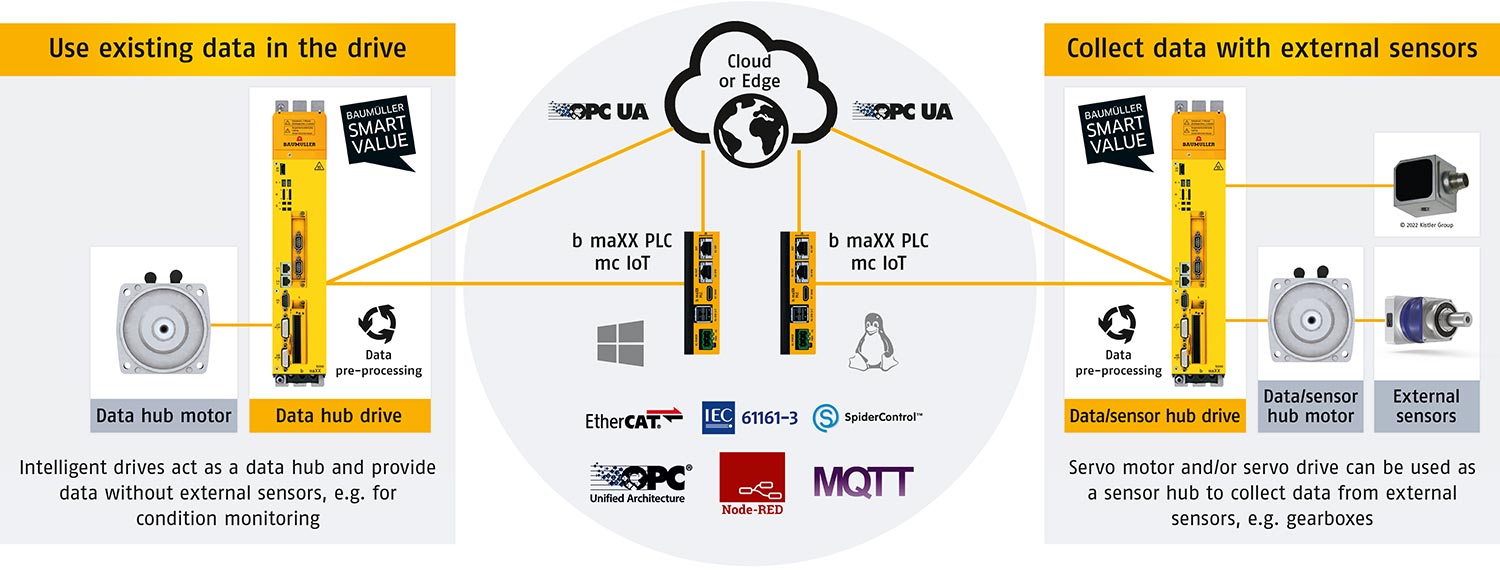

Industry 4.0: Intelligent drives function as a data/sensor hub

With the Baumüller SmartValue function, data is collected directly in the process via the intelligent sensor/actuator level, preprocessed with the help of AI and other tools, and then used to optimize the machine. Data available in the servo drive, such as power, current, torque, speed or position, are thus used intelligently - to record the current utilization of the motor-drive combination, for example. In this case, the servo drive acts as a data hub. If the available data is not sufficient, the drive and also the motor with external sensors can easily be used as a sensor hub.

Baumüller SmartValue: Smart Functions create added value

Baumüller SmartValue stands for smart functions that promise genuine additional benefits for your machines and processes. Baumüller SmartValue is the added value that smart drive technology gives mechanical engineers and machine operators. This further enhances the scope of the new b maXX 6000 devices.

You will find all the functionalities at: » Baumüller SmartValue

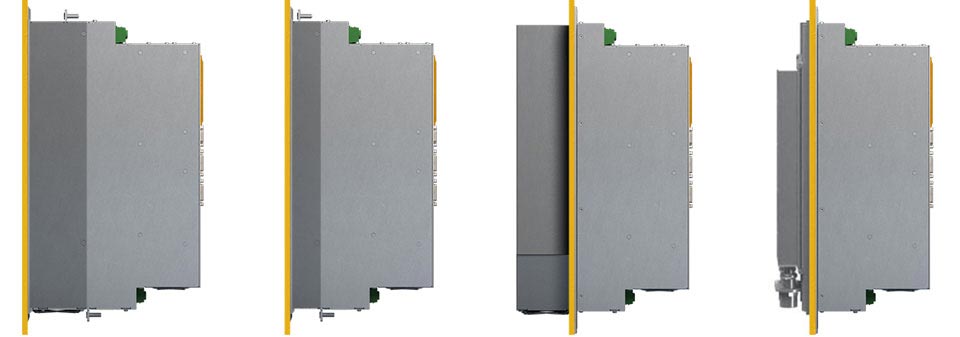

Cooling methods

f.l.t.r.: Standard cooling air, standard cooling water/oil, push-through technology air, push-through technology water/oil

Fieldbus systems

Controller functionalities

Encoder angle via field bus:

For motors with multiple windings, the encoder cable is operated without splitting.

Error response "Return motion in case of power supply failure":

In the event of a power supply failure, the drive performs positioning to a parameterizable position, provided there is sufficient energy in the DC link.

» The advantage: Protection of the machine against uncontrolled coasting down and resulting damage

Master-slave coupling for load balancing:

This feature allows the load of two drives moving a load together to be shared in a defined ratio.

» The advantage: Smaller converter technology possible › Cost savings

Cogging torque compensation:

The cogging torque of synchronous motors influences the concentricity of the motors. Cogging torques are identified by means of automated measurement and an angle-dependent current is pre-controlled. This compensates for the cogging torque.

» The advantage: Improved concentricity of the motors, in particular at low speeds › Cost savings

Single-cable solution for power and feedback systems

The single cable technology that can be fitted in Baumüller motors saves the user from having to use a feedback cable, which is usually required in addition to the obligatory motor cable. The result is a significant cost savings, as this eliminates the need for additional cables for encoder evaluation.

b maXX accessories for targeted adaptation

Match the controller and power unit features precisely to your application. You can find our servo converter accessories here.

Areas of use

- Plastics machines

- Robotics

- Packaging machines

- Filling systems

- Textile machines

- Paper and processing machines

- and many more

Write us a message, our sales experts will be happy to advise you.

Downloads

b maXX 6000

Boost your Performance – Reduce your Footprint