Drive systems for hybrid and fully electric construction machinery

Environmentally friendly and powerful alternatives to diesel

Hybrid or electric work machines are a practical alternative to diesel-powered vehicles. With their dynamic and powerful driving behavior, hybrid and electric vehicles master the usual tasks with flying colors and they do this with long operating durations, flexible charging options, and minimum noise pollution.

With its wide service range from motors, converters, and control units to diagnostic and remote maintenance software, Baumüller offers future-looking hybrid and fully electric drive solutions for mobile machinery and commercial vehicles. Baumüller Anlagen-Systemtechnik is responsible for the design and engineering of the innovative drive concepts for the mobile machines and implements them from a single source.

Traction systems – flexibly adapted to the specific requirements

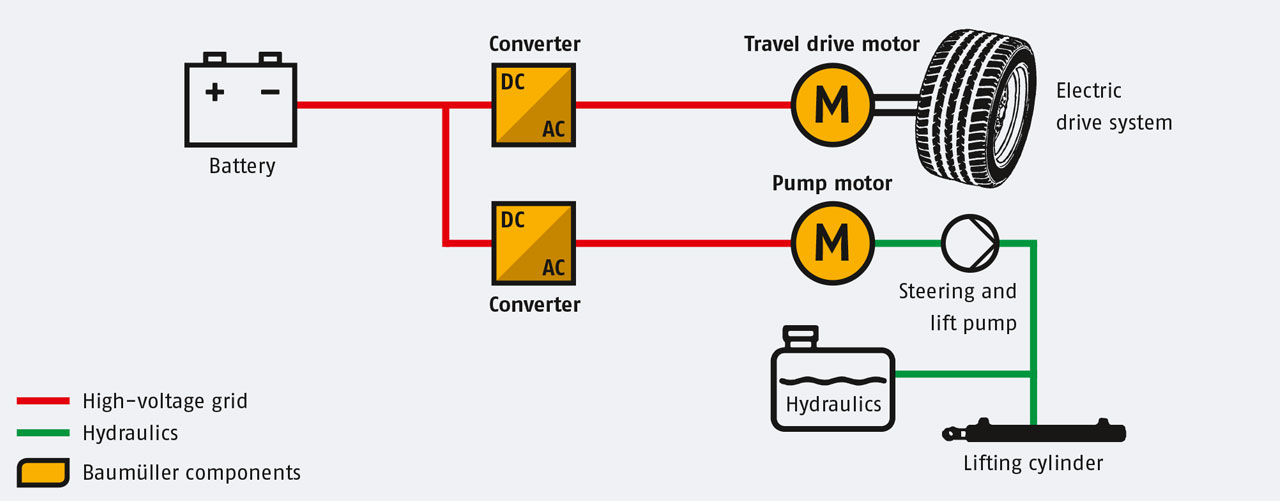

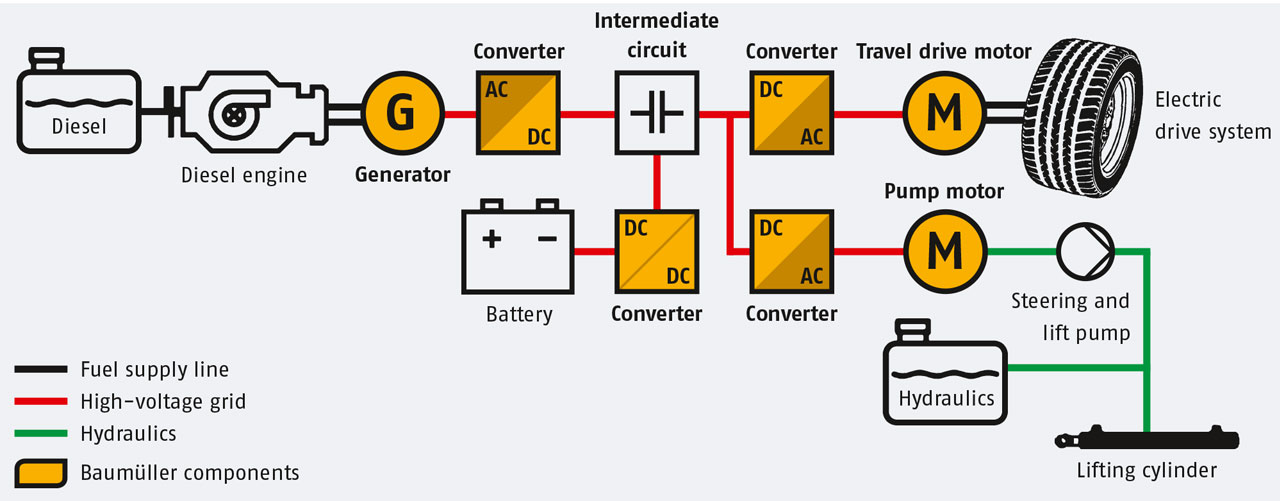

Baumüller offers two variants for traction systems: Depending on the demands placed on the machine’s autonomy on the building site and the required power input during operation, construction machinery can be equipped with a battery-powered drive or a diesel-electric hybrid system. The high starting torque increases driving comfort for the user. Recuperating braking energy allows for particularly economical operation.

There are also practical drive concepts for stationary applications with lower mobility requirements. Horizontal or vertical drilling machines, for example, can be operated from the building site power supply, with the integrated high-voltage battery covering any peak loads. Autonomy on the building site is ensured by a small power unit.

Auxiliary units – servo-hydraulics increase efficiency

In addition to traction systems, Baumüller also offers the electrification of auxiliary units. These include electrically driven hydraulic pumps for working hydraulics or electric power take-offs (ePTOs). Low-noise and low-emission driving and working are just two of the numerous advantages.

Efficient and robust drive systems

The installation space of the drives is optimized and they can be flexibly integrated into the design of the construction machine. Efficient servo-hydraulics enable electrical decentralized auxiliary drives to selectively switch the pressure and volume flow rate and control the demand-based pump output. The high starting torque increases driving comfort for the user. The recuperation of braking energy makes operation particularly economical. What you get, therefore, is an efficient and robust drive system, especially for mobile machines.

Baumüller customers profit from:

- Experience: Extensive record of successful projects

- Focus on the future: Efficient and powerful hybrid and fully electric drives

- Expertise: System integrator with its own products for E-mobility

- Customized scope of services: From engineering to service, tailored to your requirements

- Specialists in electromobility: From drive design to commissioning

- Full flexibility: Supplier network, adaptations to standard products possible

- Manufacturer independence: System solutions with Baumüller drive technology or in combination with products from other manufacturers

- Worldwide service

Baumüller is your reliable partner for hybrid and fully electric electromobility solutions.

Non-binding Request - Contact our expert!

Proven technology for modern e-drive systems

Hybrid and fully electric construction machines have decisive advantages over machines with conventional hydraulic drive technology: higher energy efficiency, lower operating costs, and lower maintenance costs. In addition, hardly any fluids are used. No oil, no cooling water and, in the case of fully electric machines, no diesel. Less damage to the environment with a smoother and more accurate operational profile at the same time. A clear advantage for modern e-drive systems.

Fully electric and emission-free: Construction machinery with battery-powered drive

Quiet and completely free of fine particulates: These are the main advantages of a fully electric or battery-run e-motor for construction machinery. The motors are run completely with rechargeable lithium-ion batteries, without any diesel engines.

Your advantages with a pure e-drive (fully electric systems)

- Highly energy-efficient – lower consumption than with conventional solutions

- Fully practical – due to quick charging concepts and state-of-the-art rechargeable battery technologies

- Low noise – The motor is barely audible and therefore much quieter than a diesel engine

- Emissions-free – no CO2 emissions

- For the fun of driving – from zero to 100 in a few seconds

Economical and powerful: Diesel-electric drives

Besides fully electric solutions, diesel-electric hybrid drives are the technology of choice when it comes to finding an economical, environmentally friendly alternative to equipping construction machinery with state-of-the-art technology.

Your advantages with a hybrid drive (combination of diesel/hydraulic & e-drive)

- Optimized drive solution – up to 30 percent fuel savings and noise reduction

- Powerful – enormous increase in efficiency

- Automatic energy recovery – battery charges itself automatically thanks to recuperation

- Quickly charged – not dependent on charging stations

- For large distances – thanks to the combustor, large ranges are possible

Charging systems for hybrid and fully electric construction machinery

The electrification of construction machinery creates a demand for high-performance charging infrastructure. Baumüller closes the gap from the drive system to the charging station and offers the full range of charging technology for rapid charging systems.

We give you exactly the support you need and will take on projects for charging technology only, or projects for both charging and drive technology, and will work with you to close the gap that you need for an order.

Baumüller customers profit from:

- Our own wide range of products and services ranging from converters to energy and battery management systems

- Expertise: High-quality and reliable products for charging stations

- Integrated engineering

- Quick and customer-oriented decision-making paths: Experience and advantages of a globally active, successful, and innovative family company with tradition

- Worldwide service

The TRADUS tractor as a drive solution: Engineered to be electric from the ground up for use in mobile machinery

Engineered to be electric from the ground up, TADUS Technologies developed the TADUS tractor together with Baumüller, a tractor that is perfect for use as a mobile work machine in the construction, forestry, and municipal sectors, among other things. Thanks to a frame structure fit for universal use, it allows the easy mounting of commercial vehicles for off-road and on-road use, such as wheel loaders or backhoe loaders, but also other vehicles such as street sweepers. The advantages of the tractor also come into their own in this vehicle category.

Smart drive solutions for drilling systems and rigs

Baumüller’s fully electric and hybrid drive solutions are also perfect for drilling systems, drilling rigs, and drilling machines. In such applications, the drilling drive can travel in a horizontal and vertical direction as well as a combination of both directions as a drilling line.

The drive concepts are developed precisely for all drilling positions as well as for a wide variety of materials to be drilled. The techniques of the drilling rigs range from earth drilling to application areas with rocks, such as tunnel drilling. In addition to horizontal drilling technology, drive concepts can be designed for all standard drilling methods.

Turnkey drive solutions for electrically operated drilling rigs

The drive technology developed by Baumüller has made a significant contribution to the success of Max Wild’s electrically operated drilling rig. By dispensing with environmentally hazardous hydraulic oil, the machines can also be used in ecologically sensitive areas, such as nature and water reserves. Coordinated drive components consisting of electric motors and b maXX converters from Baumüller take care of the feed of the carriage and drive the drill pipe. Baumüller’s turnkey drive solutions made it possible to perfectly combine environmental friendliness and high performance. The drilling rig has a nominal traction force of 250 tons and manages peak traction forces of up to 450 tons for short periods – and this for drilling over a distance of up to two kilometers.

With Baumüller drive technology: TU Munich team wins international competition for the best tunnel boring machine

With Baumüller drive technology: TU Munich team wins international competition for the best tunnel boring machine

The tunnel boring machine works according to the pipe-jacking method, which is also used in the standard tunnel boring machines currently in use. The team opted to use water-cooled synchronous motors of the Baumüller DSC series in size 45 as the drill head drive.

Read more.