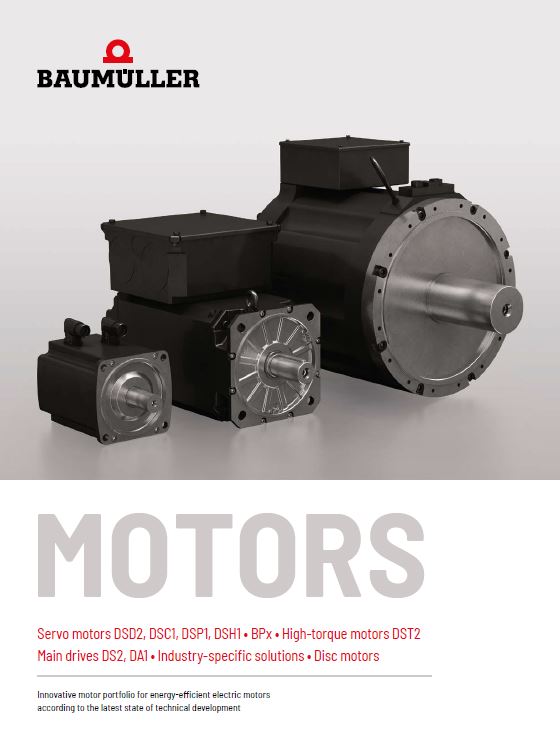

Increased productivity through dynamic DSD2 servo motors

![]()

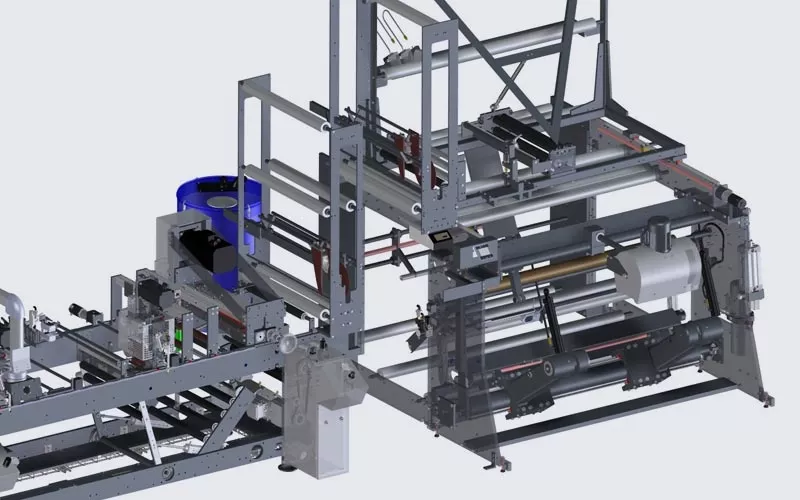

The DSD2 motors are suitable for highly dynamic applications with the highest acceleration capacity requirements, and the best start-stop qualities. This motor series covers a nominal speed range from 1000 to 6000 min-1. The DSD2 motors are highly dynamic, their speed and position are very easily controlled, making them ideally usable for applications, for example, in packaging machines, textile machines, plastics machines, handling machines, special machines, and small robots.

The DSD2 series servo motors have an excellent torque-to-inertia ratio. This ensures maximum dynamics, i.e. fast and precise production. The high dynamics reduce machine cycles. This increases the productivity of your machine.

This also contributes to the conservation of resources and the reduction of energy costs.

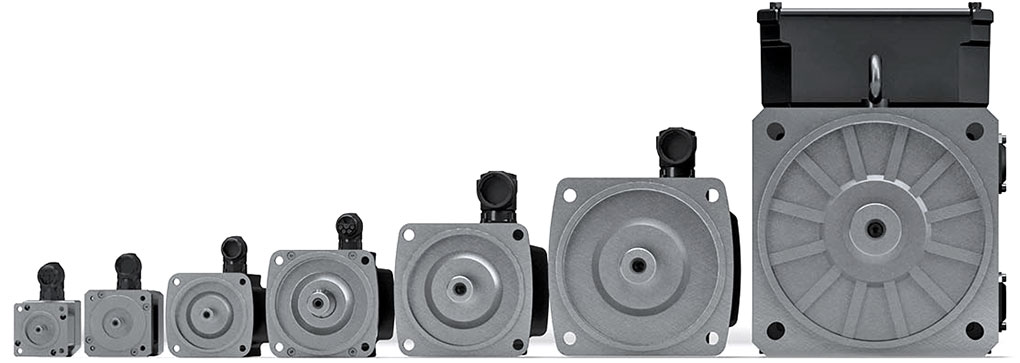

The DSD2 motors are available in sizes 28, 36, 45, 56, 71, 100 and 132. Thanks to the smooth housing surface, the motors are not susceptible to dirt. An additional advantage is the series’ simple assembly.

Another advantage: Compared to asynchronous motors, the DSD2 series has a convincingly high efficiency. The energy-efficient solution reduces the machine footprint long term. The motors are robust, low-maintenance and very durable.

Renowned customers in the packaging, textile, plastics and metalworking industries opt for Baumüller DSD2 motors:

Bagged - Fast and Safe

An ingenious solution: From metal wool to metal fiber yarn

Punching machine

Film bag machine

Properties

- Highest dynamics due to excellent torque-inertia ratio

- Degree of protection up to IP 65 regardless of the cooling method

- Main connection via rotatable plug or terminal box

- Single cable technology available

- Very good concentricity properties

- Almost cogging torque free

- Smooth housing surface - not susceptible to dirt

- Slim, integrated housing design

- Permanent magnet synchronous servo motors

- High overload capability

- Encoders: Resolver, SinCos (optional), digital encoders (optional)

- All types optionally with brake

Cooling methods

uncooled

air-cooled

water-cooled

The DSD2 range is available in uncooled, air-cooled and water-cooled versions.

Spectrum

Power

Torque

Acceleration

► Learn more about cooling options in the Baumüller Motion Arena!

Servo-hydraulic drive

Our DSD2 servo motor is suitable for use as a servo-pump drive. The quantity and pressure of a directly connected fixed displacement pump can be controlled precisely thanks to the dynamic motor speed. All motors are available in an air-cooled and a water-cooled version. The DSD2 is also available with oil cooling. This is an advantage in the hydraulic system since the oil is available in the machine anyway. The advantage: Liquid-cooled motors have a higher power density and can therefore have smaller dimensions.

In the Standard Line, the attachment is made using the conventional solution of coupling and pump support. The second development stage, the Advanced Line, describes the direct attachment of the pump on the motor via internal toothing. Here, there is no need for a pump support and coupling, so the system is more compact and robust. In the third stage, the Performance Line, the hydraulic fluid is additionally used for intelligent circulating oil lubrication. For this purpose, connections were added not only to the motor but also to the fixed displacement pump, allowing the leakage flow of the pump to be used for the permanent lubrication of the toothing. This eliminates an otherwise necessary grease lubrication of the internal toothing, which would be due every 3,000 operating hours on average, and the system is particularly robust. Baumüller thus offers a patent-pending solution, which leads to significantly reduced service costs in operation.

DSD2 motors suitable for Standard Line: sizes 45, 56, 71, 100 and 132

DSD2 motors suitable for Performance Line: sizes 56, 71, 100 and 132

DSD2 motors suitable for Advanced Line: size 100

Technical Data DSD2 servo motors

Subject to change. The values specified are maximum values.

For details, please refer to the technical documentation.

Optionally with planetary gearbox

Our BPx planetary gear series is perfectly matched to our DSD2 servo motors, and is therefore ideally suitable for applications with the highest torque and dynamics requirements. With almost any combination option possible, BPx enables you to achieve a large number of gear transmission ratio increments. You can therefore optimally adapt our motor-transmission combinations to your specific applications. The three series of Baumüller planetary gears ensure that compact and economic drive solutions are achieved at the highest technical level.

Write us a message, our sales experts will be happy to advise you.