High-torque motors DST2

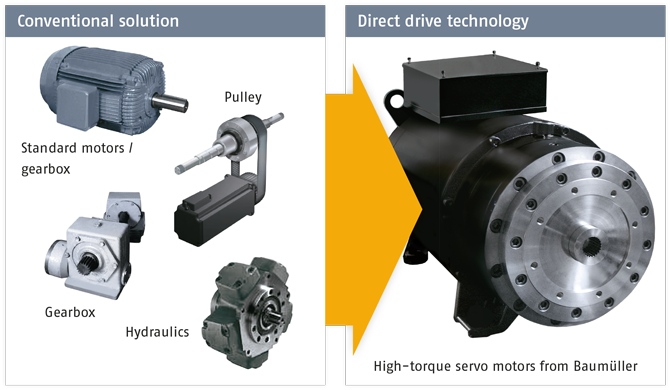

Today’s machine concepts have to meet strict requirements. Along with increased productivity and availability, as well as greater energy efficiency, cost reductions must also be achieved with the drive system. But with high-maintenance -transmissions and inefficient standard motors or hydraulic systems, these goals are not met.

►Learn more about direct drive technology in the Baumüller Motion Arena!

►Successfully integrating direct drive technology in your machines!

A high-torque motor is a multi-pole electric direct drive with very high torque. Compared to a motor-transmission combination, a high-torque motor can increase productivity of the machine while simultaneously reducing operating/energy costs.

► How to integrate a direct drive into your machine: Installation options for torque motors

► How to integrate a direct drive into your machine: Installation options for torque motorsPowerful direct drive technology with up to 60,000 Nm

Gearless drive technology offers great advantages as an alternative both to the motor-transmission combination and to hydraulic systems. The reduced service costs without the transmission or hydraulic systems, the simplified assembly and logistics due to the smaller number of components, and the high efficiency and productivity account for the attractiveness of gearless drive solutions.

The torque spectrum starts at 325 Nm and extends to a peak torque of 60,000 Nm.

Baumüller is a pioneer in direct drive technology and has had high-torque servo motors in its product program since 1991.

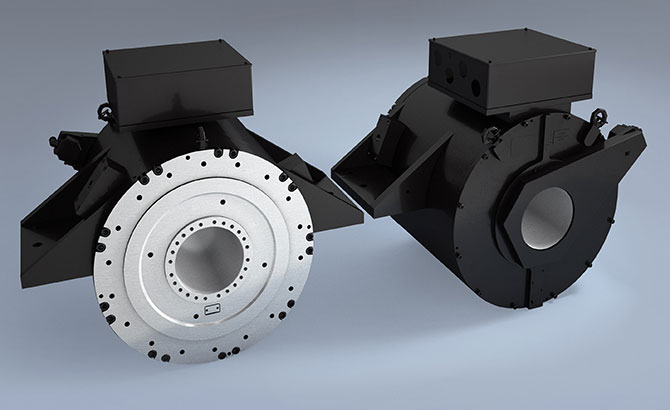

Wide selection of high-torque motors

With high-torque motors in the DST2 series, Baumüller offers a powerful gearless drive technology for low-maintenance and energy-efficient solutions. The high-torque servo motors are currently available in six sizes between 135 and 560, and depending on size can reach speeds up to 2000 min-1 and an output of 1150 kW.

In addition to the solid shaft version, the direct drives are also universally available with hollow shaft or integrated thrust bearing. The different designs of the DST2 motors ensure a a greater degree of freedom in construction and allow for optimal integration of the motor with the machine concept. The high-torque motors DST2 thus provide an optimal solution for many machine types in different applications and are an electrical alternative to hydraulic applications.

► Time to make the change – Understanding and successfully implementing direct drive technology

► Time to make the change – Understanding and successfully implementing direct drive technologyHigh torque for industrial use

With a maximum torque of up to 60,000 Nm, the motors are suitable for use in various machines and systems, such as servo presses, extruders and shredders. The water-cooled high-torque motors offer very high torques even at low speeds and also impress with outstanding true running characteristics, a robust design and a smooth housing surface that is not susceptible to accumulating dirt.

Your benefits at a glance

With direct drive technology you benefit from many advantages, such as

- Excellent smooth-running characteristics

- Energy-efficient thanks to the high level of efficiency in the drive package

- High torques at low speeds

- Low noise

- Water cooling unit of stainless steel

- Compact and robust construction

- Smooth housing surface - not susceptible to accumulating dirt

- Permanent-magnet high-torque motors

- Protection class IP54

- Encoders: Resolver, SinCos (option),

- Digital encoders (option)

- Other encoders on request

In the video you will learn more about the cooperation with WEIMA Maschinenbau GmbH and get to know our drive solution for shredding systems:

I agree that external content may be displayed to me,

which means that personal data may be transmitted to third-party platforms.

Read more about this in our privacy policy.

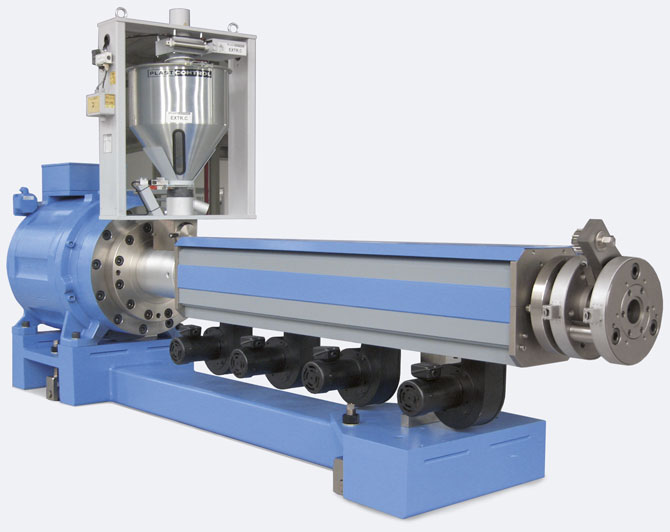

DST2 motors for extruders

The precision control dynamics of the rotor ensure synchronous running and constantly high-quality.

The precision control dynamics of the rotor ensure synchronous running and constantly high-quality.

Energy-efficient direct drives reduce the lifecycle costs of your extrusion systems and also allow for a compact machine construction.

Many market leaders rely on water-cooled DST2 high-torque motors from Baumüller to power an extrusion screw. The low-noise direct drive without gears has a compact structure and offers maximum torque at minimum speeds. Without the gears, transmission and belts, a more compact machine construction is possible with significantly reduced service requirements. What is particularly important for the extrusion technology is that the motor has an integrated thrust bearing that absorbs the rear-acting axial forces arising in the process section.

In an interview with our customer Bemaco Engineering, you can find out more about a Coex system that has been equipped with our drive technology:

I agree that external content may be displayed to me,

which means that personal data may be transmitted to third-party platforms.

Read more about this in our privacy policy.

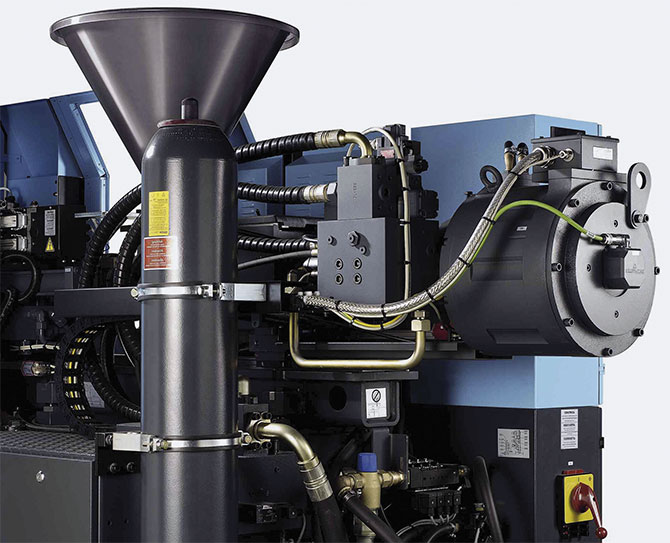

DST2 motors for injection molding machines

Short cycle times, maximum precision and reduced energy costs

Short cycle times, maximum precision and reduced energy costs

At many leading manufacturers of injection mold machines, hydraulics are gradually being replaced with gearless drive technology from Baumüller. We draw on our extensive experience in this market segment and together with you are developing systems with very high energy efficiency and productivity.

DST2 motors for printing machines

In the area of printing machines, Baumüller has done pioneering work as a system manufacturer with direct drive technology. While in the past, synchronized rotating cylinders were commonly powered by forced coupling via hard gearing, today manufacturers are increasingly relying on direct drive technology from Baumüller and are profiting from the many advantages.

In the area of printing machines, Baumüller has done pioneering work as a system manufacturer with direct drive technology. While in the past, synchronized rotating cylinders were commonly powered by forced coupling via hard gearing, today manufacturers are increasingly relying on direct drive technology from Baumüller and are profiting from the many advantages.

Powerful and clean alternative for ships

The high-torque motors DST2 are certified by the Lloyd's Register and meet the specific requirements for shipping. The water-cooled direct drives are constructed with protection class IP 54, are not susceptible to dirt accumulation and run with low noise. With their compact and robust construction, the motors take up minimal space in the engine room and are well suited for rough conditions on the water

The motors can optionally be ordered with wing mounts. Here, the feet are diametrically arranged on the outer diameter of the motor to facilitate integration into the ship's structure. High torques, good smooth-running properties and energy efficiency thanks to a high level of efficiency make the high-torque motors ideally suited for demanding applications Since in hybrid ship drives, unlike diesel-operated ships, the full torque is already available from the beginning in the lower rotational speed range, maneuverability is significantly improved.

The motors can optionally be ordered with wing mounts. Here, the feet are diametrically arranged on the outer diameter of the motor to facilitate integration into the ship's structure. High torques, good smooth-running properties and energy efficiency thanks to a high level of efficiency make the high-torque motors ideally suited for demanding applications Since in hybrid ship drives, unlike diesel-operated ships, the full torque is already available from the beginning in the lower rotational speed range, maneuverability is significantly improved.

![]()

DST2 high-torque motors are available in water-cooled versions.

Technical data — DST2

*) on request

Subject to alterations. The stated data are maximum values.

For details please have a look in the technical documentations.

Write us a message, our sales experts will be happy to advise you.

Downloads

Direct Drives