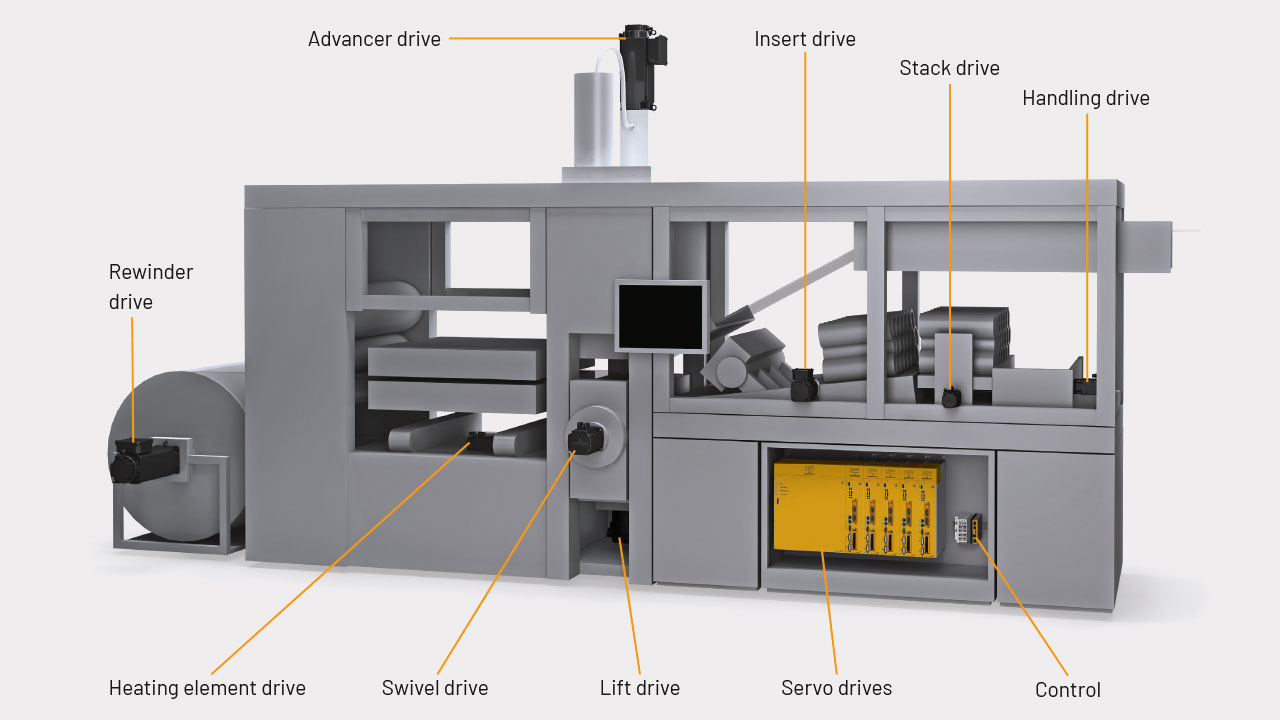

Baumüller offers a complete automation solution for fast and high-precision thermoforming machines. From dynamic, water-cooled servo motors to reduced heat input to the machine to control using pre-assembled motion modules, e.g. for temperature regulation, Baumüller offers the full system of hardware and software. Here, also, the compact and flexible modular system b maXX 5300 offers many advantages.

Topology

Benefits of the electric drives and automation

Automation & technology functions

- Exact and dynamic temperature control of the heating elements helps to save energy

- Cam disk technology, e.g. in the lift drive, avoids erratic movements, and ensures optimized movement sequences

- Optional: touch probe for fast reading of synchronization markings, and therefore for exact cutting to size of material

Motors

- Extremely robust motors for high shock and vibration loads in swivel, lift or advancer drives, among other things due to special bearing and casting technology

- Motors with excellent acceleration properties for high cycle rates

Servo drives

Clever drive topology by using the DC link system:

- Storage of energy in the DC link or in additional capacities to provide energy again when it is needed t higher energy efficiency with lower energy costs

- The electrical drive output can therefore be dimensioned to be smaller and more economical if necessary

- Due to the energy stored in the DC link, controlled shutdown of the system in the event of faults is possible, e.g. in case of power outages

- Compact modular system saves space in the control cabinet

Are you interested in buying our products?

Write us a message, our sales experts will be happy to advise you.

Baumüller products