Sustainable drive solutions for plastics machines

Numerous companies from a wide range of fields in the plastics sector have been relying on the innovative capacity and expertise of Baumüller for years. Baumüller also plays an important pioneering role in the development of high-torque motors and the servo pump solution.

Baumüller offers dynamic and precision application solutions from a single source. We develop innovative and tailored solutions according to your requirements, which are implemented either as an individual module or a complete system and provide you with decisive competitive advantages.

► Learn more about servo hydraulics in the Baumüller Motion Arena!

Plastic is one of the most diverse and adaptable materials in the world. Numerous industries use it. However, virgin material is becoming increasingly less abundant. A rethink is the order of the day. An increasing number of plastic processors now use recycled material. The recyclate fraction is expected to rise to around 50 percent by 2050.

Sustainability and Circular Economy

Global warming and the measures introduced by politicians to meet global climate targets are giving the issues of sustainability and the circular economy a considerable boost. The processing of recyclate, the design and use of thin-walled products in order to reduce the use of material or, for example, the substitution of heavy metallic materials with plastics in the area of e-mobility are being implemented with ever greater consistency.

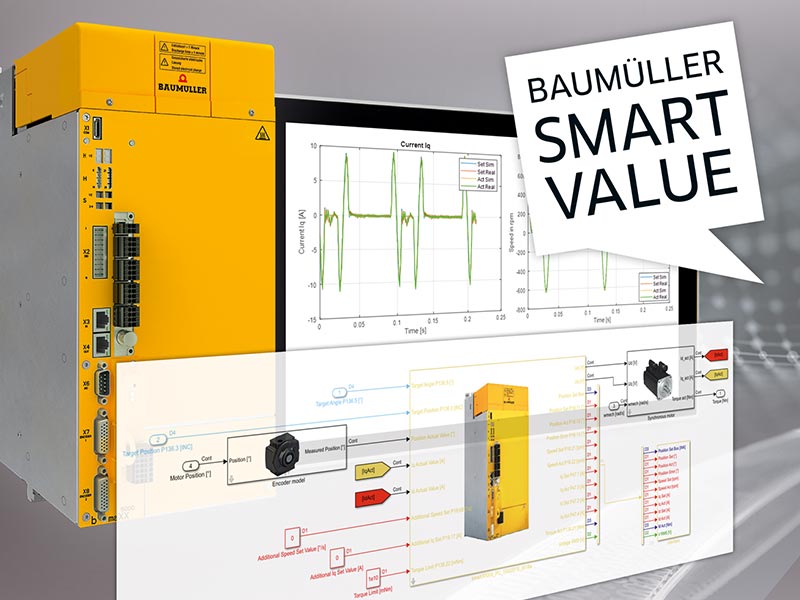

Digital tools

for the optimum

Digitalization also plays an important role in the ambitious climate targets. It is a powerful tool for using the potential of the drive technology with optimal manpower and resources efficiently, for example, by using simulation software: With the help of the digital twin, drive components can be designed efficiently and put into service virtually. Another example are the modern communication interfaces for intelligent machine communication in the production cluster, with peripheral devices or, for example, with downstream and upstream value-adding steps.

Efficient drive technology versus rising energy costs

The use of electric drive technology with its high precision and dynamics makes an important contribution to high productivity with very good process reliability. This reduces rejects to a minimum and therefore enables further savings. In addition, energy-efficient drive concepts help to reduce the overall energy requirements. Baumüller offers a very suitable portfolio of solutions for the electrification of the drive axes in plastics machines. This enables the realization of hybrid and fully electric machines.

► How to integrate a direct drive into your machine:

► How to integrate a direct drive into your machine:Installation options for torque motors

Handling systems

Handling systems

Baumüller also offers economical and efficient solutions for your material handling application as well as for the finishing and further processing of plastic parts in such areas as insertion, removal, deburring, assembly or sorting. From motors, converters and control technology to control systems and software solutions for motion functions, Baumüller offers a wide range of handling and automation concepts.

► The Best of Both Worlds:

► The Best of Both Worlds:Combine Hydraulic and Servo Technology and Save Up To 80% of Energy Costs

References:

Write us a message, our sales experts will be happy to advise you.

Our drive technology for your plastics machines:

Our motors for your plastics machines:

Our controllers for your plastics machines:

Downloads

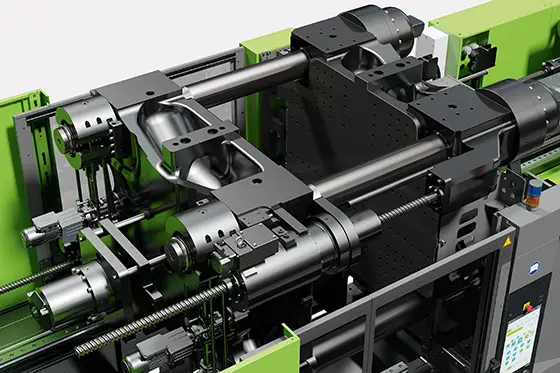

Baumüller offers a comprehensive portfolio for hydraulic, hybrid and fully electric injection molding machines. These servo pump solutions have been reducing the energy requirement in hydraulic and hybrid machines for many years. For fully electric

Baumüller offers a comprehensive portfolio for hydraulic, hybrid and fully electric injection molding machines. These servo pump solutions have been reducing the energy requirement in hydraulic and hybrid machines for many years. For fully electric  Baumüller offers energy-efficient direct drive technology for

Baumüller offers energy-efficient direct drive technology for  Baumüller's servo pump solution is the optimum solution for reducing the energy requirement in

Baumüller's servo pump solution is the optimum solution for reducing the energy requirement in  Baumüller offers a complete automation solution for fast, high-precision

Baumüller offers a complete automation solution for fast, high-precision  Recycling and reusing plastics to reduce the use of resources is a sustainable solution. The use of recyclate helps to decrease CO2 release. We offer highly efficient drive systems that help to reduce emissions. Green and high-precision synchronous motors also offer a very high efficiency within the partial load range and are therefore ideally suited for

Recycling and reusing plastics to reduce the use of resources is a sustainable solution. The use of recyclate helps to decrease CO2 release. We offer highly efficient drive systems that help to reduce emissions. Green and high-precision synchronous motors also offer a very high efficiency within the partial load range and are therefore ideally suited for  The use of direct drive technology makes it possible to produce very high-quality films, since torque fluctuations can be reduced even at low speeds by eliminating the need for gears. The cogging torque is almost completely compensated by specific functionalities in the converter in conjunction with the servo motors. Perfect for

The use of direct drive technology makes it possible to produce very high-quality films, since torque fluctuations can be reduced even at low speeds by eliminating the need for gears. The cogging torque is almost completely compensated by specific functionalities in the converter in conjunction with the servo motors. Perfect for