The use of direct drive technology enables the production of very high-quality films, as the lack of gearing means that torque fluctuations can be reduced even at low speeds. With specific functionalities in the converter combined with the servo motors, the cogging torque is almost fully compensated.

Using the flexible modular system, machine modules can also be easily connected for further processing.

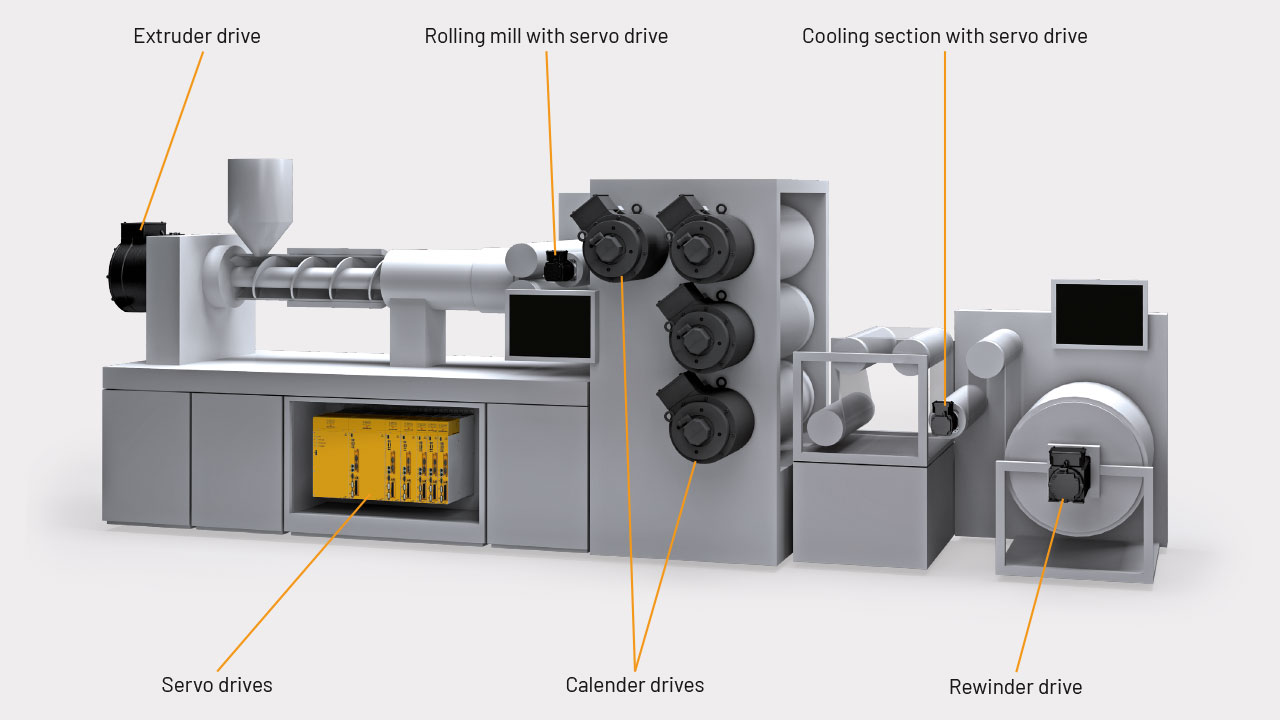

Topology

Benefits of the electric drives and intelligent controller functions

Extruder drive

- high energy efficiency due to synchronous technology

- precise speed control in the drive and therefore high product quality in the calender raw material

- coaxial structure for extruder screw enables compact machine construction

- intelligent “screw relaxing” controller function for gentle torque dissipation before switching off the extruder to protect the mechanics

Calender drive

- virtually cogging-torque-free motors in combination with intelligent drive functions for cogging torque compensation enable high foil quality

- precise speed control of the drive axes leads to optimal foil thickness and foil surface

- high torque density and compactness of the motors help to realize smaller center-to-center spacings of the rollers

Rewinder

- Further weak field area of the motors enables optimal and economic dimensioning of the drive technology -> Space saving in the control cabinet

Are you interested in buying our products?

Write us a message, our sales experts will be happy to advise you.

Baumüller products