Hybrid ferry with Baumüller drive system

Environmentally Friendly Across the Weser River

Diesel generators and electric motors are a successful combination and the perfect way to achieve more environmental protection and fuel savings. On the new ferry Farge, which transports vehicles and people across the Weser near Bremen, there is such a hybrid drive system that ensures significant fuel savings, minimal emissions and an improved maneuverability.

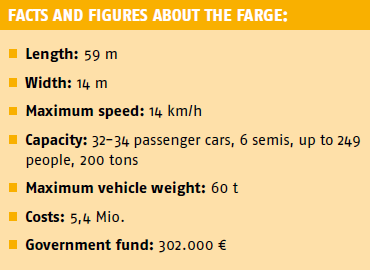

The engine room of the Farge: the diesel motors working as generators to generate electrical energy | Image: Irene NeumannTunnel or ferry? That is the question that car and truck drivers near Bremen have to ask themselves every day. Traffic jams and construction work meant that more and more vehicles, including heavy semi trucks, were crossing the Weser by ferry than through the tunnel. It is a reason for the operator of the ferry company Fährgesellschaft Bremen-Stedingen (FBS) to be happy and ultimately a reason for the new construction of a ferry for transport between Berne in Lower Saxony and the Bremen district of Farge. The result is an efficient and environmentally-friendly ship with a previously unique drive system, with which the FBS not only meets current environmental requirements, but even significantly exceeds them. The ferry is the first hybrid passenger and vehicle ferry in this size class in Germany. The FBS is thus assuming a pioneering role in terms of innovative environmentally-friendly ferries.

The engine room of the Farge: the diesel motors working as generators to generate electrical energy | Image: Irene NeumannTunnel or ferry? That is the question that car and truck drivers near Bremen have to ask themselves every day. Traffic jams and construction work meant that more and more vehicles, including heavy semi trucks, were crossing the Weser by ferry than through the tunnel. It is a reason for the operator of the ferry company Fährgesellschaft Bremen-Stedingen (FBS) to be happy and ultimately a reason for the new construction of a ferry for transport between Berne in Lower Saxony and the Bremen district of Farge. The result is an efficient and environmentally-friendly ship with a previously unique drive system, with which the FBS not only meets current environmental requirements, but even significantly exceeds them. The ferry is the first hybrid passenger and vehicle ferry in this size class in Germany. The FBS is thus assuming a pioneering role in terms of innovative environmentally-friendly ferries.

The FBS commissioned SET Schiffbau- und Entwicklungsgesellschaft [shipbuilding and development company] in Tangermünde with the construction of the innovative ferry. The specialist for electric drive technology Baumüller, based in Nuremberg, was responsible for the propulsion system. In close cooperation with the shipyard, the Baumüller subsidiary Anlagen-Systemtechnik took over the complete engineering of the propulsion system, which is a combination of Baumüller products and third party components, such as batteries. In addition to the drives and control cabinets, Baumüller also supplied special software for energy management on board.

The FBS commissioned SET Schiffbau- und Entwicklungsgesellschaft [shipbuilding and development company] in Tangermünde with the construction of the innovative ferry. The specialist for electric drive technology Baumüller, based in Nuremberg, was responsible for the propulsion system. In close cooperation with the shipyard, the Baumüller subsidiary Anlagen-Systemtechnik took over the complete engineering of the propulsion system, which is a combination of Baumüller products and third party components, such as batteries. In addition to the drives and control cabinets, Baumüller also supplied special software for energy management on board.

►Efficiency in sight! Hybrid or electric ship propulsion isn't rocket science – this is what you need to consider

The technology

The principle of the ferry is that diesel engines and electric motors are skillfully combined to produce maximum efficiency. Three diesel engines are on board, of which only two are regularly in operation and one is considered as an emergency generator. In total, the so-called generator power units provide a total capacity of over 1300 kVA. The diesel engines only act as generators and as such are no longer exposed to power peaks, as would be the case with direct use as propulsion. As a result, the diesel engines are always operated with optimal efficiency and can be smaller right from the start. Excess energy produced by the generators or returned to the system through feedback is stored in batteries instead of being lost as heat as was previously the case. All batteries are housed in a separate battery room and have a total capacity of 80 kWh. Power peaks that are required by the drive are therefore not transmitted to the generators, but rather are absorbed with energy from the batteries. The ferry can thus even drive completely electrically for a corresponding amount of time in “green mode.” If necessary, the entire system can even be converted to alternative energy storage system, explains Swen Jacob, regional manager for the North and Scandinavia at Baumüller, if, for example, the technology is one day ready for the use of hydrogen drives.

The batteries are housed in a separate battery room and have a total capacity of 80 kWh | Image: Irene NeumannThe ferry is driven by four drive propellers: two in the front and two in the rear. These are powered by four electric motors, type DS2-200 from Baumüller. These are synchronous motors, which offer a particularly high acceleration capacity and a very high power density. The motors are available in air and water-cooled designs and are used in the water-cooling version in the ferry.

The batteries are housed in a separate battery room and have a total capacity of 80 kWh | Image: Irene NeumannThe ferry is driven by four drive propellers: two in the front and two in the rear. These are powered by four electric motors, type DS2-200 from Baumüller. These are synchronous motors, which offer a particularly high acceleration capacity and a very high power density. The motors are available in air and water-cooled designs and are used in the water-cooling version in the ferry.

The operator saves a significant amount of fuel by combining the diesel and electric motors in the ferry. Since less fuel has to be burned, the system emits fewer pollutants than the drives of the previous models purely powered by diesel. This is supported by using state-of-the-art exhaust filters. The ferry therefore significantly exceeds all legal environmental requirements and is so environmentally friendly that even the Federal Ministry of Transport and Digital Infrastructure supports it financially.

The best maneuverability

In addition to its environmental friendliness and the low fuel costs, the Farge offers another advantage with its hybrid drive system: The ship's maneuverability is significantly improved by the properties of the electric motors. The reason for this is that electric motors respond more immediately to adjustments in speed and torque, which also improves the responsiveness and thus the maneuverability of the ship. This is an important point if you consider that the Farge only covers a short distance of about 400 meters from one bank of the Weser to the other and is virtually constantly docking and casting off.

Another advantage can be clearly noticed by everyone on board at all times. The reduction from six to just three diesel engines leads to a significantly lower noise level. The running smoothness of the electric motors also positively affects the ride.

Technical highlight: Self-regulating energy and battery management

Managing director of FBS, Andreas Bettray, thanks Swen Jacob from Baumüller for the good cooperation I Image: Irene Neumann

Managing director of FBS, Andreas Bettray, thanks Swen Jacob from Baumüller for the good cooperation I Image: Irene Neumann

A technical highlight of the Farge's drive concept is the battery and energy management system. The software programmed by Baumüller ensures that the drives always run as efficiently as possible. The system independently regulates how many diesel engines are in operation or how much energy is taken from the batteries, for example. A monitor in the engine room and a monitor on the control console each clearly show information about the current operating status of all drives and batteries. The captain and machinist are thus always informed and additional energy and thus fuel are saved by the system's self-regulation.

The ferry's successful and innovative equipment was made possible by the fact that Baumüller's system company, Baumüller Anlagen-Systemtechnik, brought many years of expertise in drive technology as well as experience in the equipping of ships and the programming of energy management systems for industrial system and marine applications to the project.

Hybrid ferry Farge: Baumüller equips the drive system with the latest technology

https://youtu.be/Ftz_zIDqeIk