Hybrid marine power from Baumüller

30% less diesel consumption with significantly higher power

For several months a new work boat has been traveling along the North Sea coast: the Trischen. Economical, environmentally and equipped throughout with the latest technology, the new coastal work boat is evidence that alternative marine propulsion solutions have long since come on board.

“We have met all the requirements”, Olaf Deter, CEO of the shipbuilder company SET, was pleased to state as the Trischen was named in May 2019. The old Trischen was to be replaced after over thirty years of service. Not only was the boat new, but also the requirements set for SET by the principal, the Coastal Protection, National Park and Marine Conservation Agency of the State of Schleswig-Holstein (LKN.SH). Not only the size but also the performance and economic efficiency of the boat were to be optimal in the new boat. SET, working with Baumüller’s drive and automation specialists, integrated a diesel-electric drive system, which made a substantial contribution to this success.

►Efficiency in sight! Hybrid or electric ship propulsion isn't rocket science – this is what you need to consider

The boat: In service for coastal protection

The Trischen is deployed in coastal protection on the Schleswig-Holstein North Sea Coast and the offshore islands and the Halligen (small islands without protective dikes). The main task of the Trischen is to maintain coastal protection facilities and drainage systems so that the water from the inland can flow away freely and the waterways remain clear for shipping. To do so, it draws in water which is then injected through nozzles into deposited sediments by injection pumps, in order to loosen and wash them away. Up to 40,000 liters of water per minute swirl up the silt that is then transported away by the current. The boat can also be used as a tug, for transporting material to the islands and to the dikes or for other special deployments. One unusual use was the transport of seals: The crew of the Trischen had released several animals from a breeding station into the wild.

The new boat had to be economical to run and powerful, with a maximum draft of 1.05 meters for use in the Wattenmeer mudflats. SET was able to meet the draft requirements by widening the hull. The integration of a diesel-electric drive system makes the Trischen powerful with low fuel consumption and low emissions.

Trischen: Hybrid marine power from Baumüller

I agree that external content may be displayed to me,

which means that personal data may be transmitted to third-party platforms.

Read more about this in our privacy policy.

The drive: efficient and low-emissions

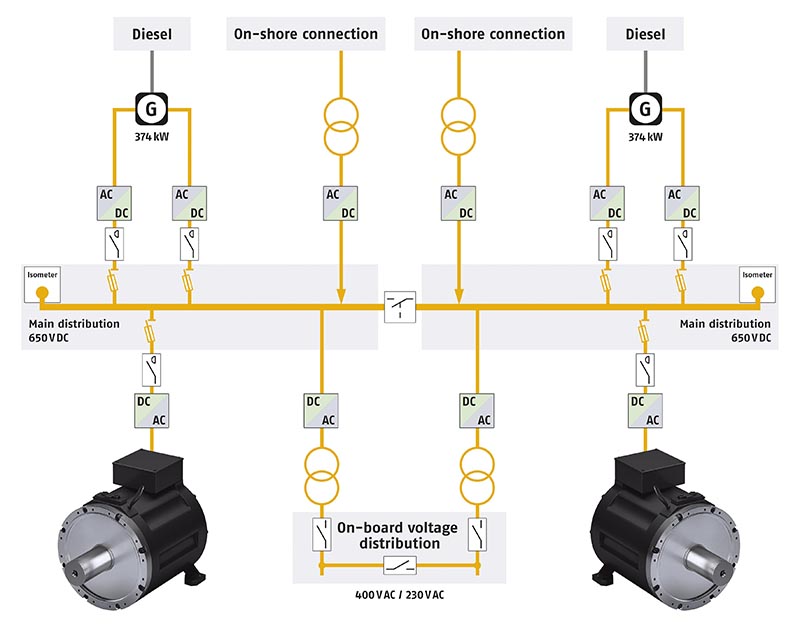

The highly modern diesel-electric drive system of the Trischen consists of two ScanDiesel power units with an output of 368 kW each and two electric propulsion motors. The drive specialist Baumüller was responsible for implementing the electric drive and pump system and, together with SET, has already launched many diesel-electric boats successfully.

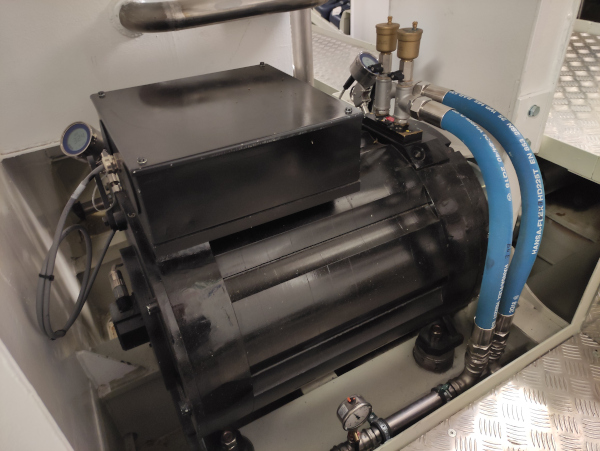

One of the two ScanDiesel power units, which supply the power for the intermediate electric circuit The diesel engines supply a total output of 736 kW, which is supplied to an immediate circuit via am AC/DC converter. The intermediate circuit and the on-board system are set up redundantly for additional safety, this means that in the event of a component failure, the boat can continue to operate with half the output. Attached to this redundant direct current intermediate circuit are two electric propulsion motors and all other loads of the boat, for example, the motors for the injection pumps with an output of 380 kW and the entire on-board system.

One of the two ScanDiesel power units, which supply the power for the intermediate electric circuit The diesel engines supply a total output of 736 kW, which is supplied to an immediate circuit via am AC/DC converter. The intermediate circuit and the on-board system are set up redundantly for additional safety, this means that in the event of a component failure, the boat can continue to operate with half the output. Attached to this redundant direct current intermediate circuit are two electric propulsion motors and all other loads of the boat, for example, the motors for the injection pumps with an output of 380 kW and the entire on-board system.

The Baumüller subsidiary, Baumüller Anlagen-Systemtechnik GmbH & Co. KG., was a valuable implementation partner for SET. The specialist for alternative marine drive systems has many years of experience in equipping boats and was thus able to provide information and support for the entire project, from the design to the programming of the HMI and the energy management through to successful commissioning.  One of the two electric propulsion drives of the type Baumüller-DST2, which are supplied from the intermediate circuit and drive the propellers directly The Trischen is driven by two water-cooled Baumüller torque motors of the type DST2, each with an output of 210 kW. In view of the small installation space available, above all the advantages of the torque motors are their high power density and extremely good compactness. Water-cooled Baumüller DS2 synchronous motors were chosen for the pump motors. Danfoss and Omron components were also used. The control cabinet construction and wiring were also undertaken by Baumüller Anlagen-Systemtechnik, which was able to meet the compactness targets with a special control cabinet layout. This was necessary as little space was available in the machine room. After programming the control unit and the energy management, Baumüller continued to support SET through to successful commissioning, as the central contact for the electric drive technology.

One of the two electric propulsion drives of the type Baumüller-DST2, which are supplied from the intermediate circuit and drive the propellers directly The Trischen is driven by two water-cooled Baumüller torque motors of the type DST2, each with an output of 210 kW. In view of the small installation space available, above all the advantages of the torque motors are their high power density and extremely good compactness. Water-cooled Baumüller DS2 synchronous motors were chosen for the pump motors. Danfoss and Omron components were also used. The control cabinet construction and wiring were also undertaken by Baumüller Anlagen-Systemtechnik, which was able to meet the compactness targets with a special control cabinet layout. This was necessary as little space was available in the machine room. After programming the control unit and the energy management, Baumüller continued to support SET through to successful commissioning, as the central contact for the electric drive technology.

Diesel-electric: the advantages

The drive system of the Trischen is a serial hybrid drive, in which the diesel engines drive the generator and the electric motors are directly responsible for driving the propellers. The most important advantage: The combustion engine is run continuously with optimum efficiency with minimum consumption and exhaust emissions. The fuel consumption therefore reduces in comparison to the conventional diesel drive with an additional 30 percent output. The additional performance increases the working speed significantly, the new Trischen can therefore now do in a week the work that previously took two to three weeks. Moderate cruising speed of the boat is possible with only one diesel engine. Compared to similar boats, the new Trischen is therefore among the top-ranking achievers when it comes to efficiency, emissions as well as running and maintenance costs.

Structure of the serial hybrid drive system, which cuts costs and reduces emissions

Structure of the serial hybrid drive system, which cuts costs and reduces emissions

The maneuverability has also improved significantly. On the one hand because the “old” Trischen was only a single propeller boat and the new boat has two propellers and a bow thruster, on the other hand due to the improved response of the electric motors. Special software functions make it possible to adjust the propulsion and response of the drive system according to the customer’s requirements or for optimum careful handling of the mechanics. Especially in working mode, the greater smooth running and lower noise level are noticeable on board. “The boat runs faultlessly, and we are pleased to go to work each day”, said a happy Christian Thiel, the captain of the Trischen and praised the reliability of the drive system.

Conclusion: Alternatives are worthwhile

The changeover of work boats, tugs, inland boats and yachts to hybrid drive systems is no longer unchartered territory. Drive specialists such as the Baumüller Group based in Nuremberg have acquired plenty of experience in recent years and are able to use many varied solutions to meet all kinds of different requirements in a targeted way. Alternative planning pays: For example, ferries benefit from improved maneuverability, yachts from lower noise emissions and work boats from the higher performance. Operators can look forward to lower fuel costs and the environment benefits from the lower emissions.