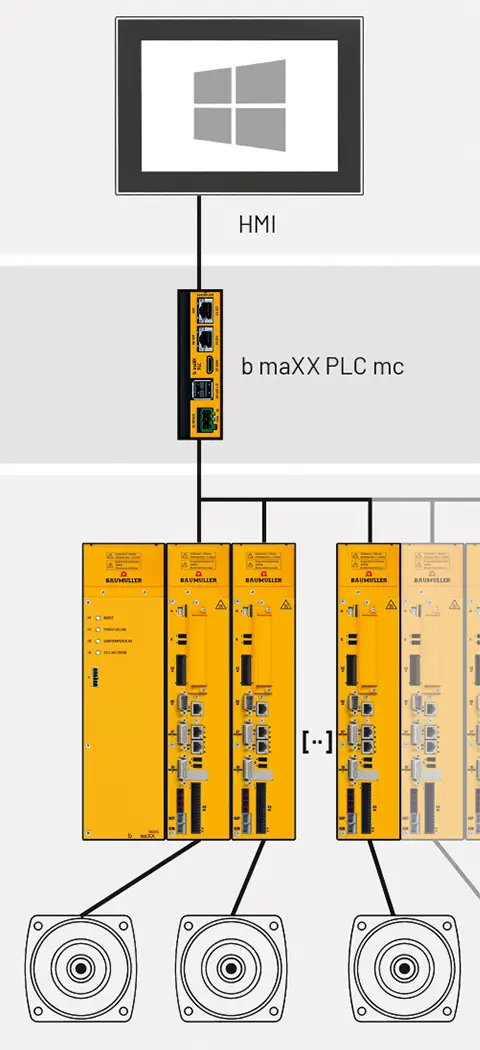

b maXX PLC mc - PLC & PC combined for central automation concepts

centralized concept  Technology function in the control unit, e.g. for web processing machines

Technology function in the control unit, e.g. for web processing machines

With the b maXX PLC mc control platform, Baumüller combines the properties of industrial PCs and PLC controls and thus covers the area between these existing solutions optimally.

The b maXX PLC mc controls motion-control applications and can be rapidly and easily deployed for high-performance automation tasks thanks to the comprehensive Baumüller technology libraries. This makes it the ideal solution for networking machines and machine modules right down to individual automation components. The compact control unit with large power reserves has an IEC 61131-3 environment for the implementation of complex control tasks.

- EtherCAT Master

- Intel Atom Multicore CPU

- 1000 MBit Ethernet

- IEC-61131-3

- Motion Control

- Coordinated Motion

Combines industry PC and classical PLC control unit on shared hardware

In addition to the actual control tasks, the combination of PLC and PC allows the possibilities of the Windows operating system to be used. By using the Intel Atom series of multi-core processors and partitioning into a real-time operating system and a Windows operating system, both of which operate independently of each other, applications can be realized that previously required at least two systems. Machine visualization is a typical example of this. This saves space in the control cabinet and reduces complexity and costs in the after-sales area – for example, with spare parts inventories.

b maXX PLC mc also offers great user-friendliness with its tool-free, externally replaceable battery for the real-time clock, for example. Likewise, a very fast non-volatile RAM memory – NOVRAM – also enables safe data storage, even in case of power failure.

Ultra-compact and powerful

The system has a convincingly handy size of 110 x 90 x 35 mm and is therefore significantly more compact than the previous control solution. The b maXX PLC mc is based on an Intel CPU system, can be used universally for almost any automation task, and can be mounted flexibly. It takes up minimal space in the control cabinet and is suitable for top-hat rail mounting. The b maXX PLC mc is also characterized by very good performance with highly synchronous real-time tasks. This allows complex applications with the highest performance requirements to be achieved.

Extensive IoT functionalities

The Baumüller b maXX PLC mc is the ideal solution for networking and controlling machines and machine modules through to individual automation components. With the b maXX PLC mc, data can be collected directly at the machine, preprocessed, and output to other terminal devices or the cloud. It makes extensive and complex data analyses possible in order to enable Industry 4.0 applications, such as predictive maintenance. At the same time, new business models such as “pay per x” can be implemented.

I agree that external content may be displayed to me,

which means that personal data may be transmitted to third-party platforms.

Read more about this in our privacy policy.

The ProDataX and Ininet SpiderControl software is also implemented on the b maXX PLC mc. This allows individual parameterization for the analysis of data through to the creation of custom dashboards. The IoT standard protocols OPC UA and MQTT are available for connectivity. This means that data can also be sent to the cloud, regardless of the respective cloud provider. This ensures interoperability at machine level.

Data from different manufacturers’ devices can be processed. Data from Baumüller products, e.g. a b maXX converter, can be output parallel to the field bus through the internal protocol and thus through the service interface. Due to the enhanced functions, the connectivity of Baumüller devices with other automation components can be established via OPC UA.

Write us a message, our sales experts will be happy to advise you.

Downloads

Automation

ProMaster, Motion Control, IoT Industry 4.0, b maXX HMI, I/O systems