Reduce your footprint: Intelligent automation solutions for optimizing your use of resources

At SPS 2021, Baumüller will give a live digital demonstration of how to sustainably reduce your footprint.

Baumüller, the specialist for automation and innovative electric drive technology, will present its solutions for increased sustainability and a reduced footprint at the SPS trade fair in Nuremberg from November 23 to 25. The focus will be on faster time-to-market, shorter commissioning times and energy-efficient manufacturing processes through clever drive concepts and intelligent functions.

Exclusively at SPS: Development innovation pushes sustainability

An exclusive innovation in the field of drive technology will be presented live and digitally in the Innovation Lab at the Baumüller exhibition stand. The new development will be shown to the public for the first time and fulfills its claim of a reduced footprint in several respects.

Baumüller SmartValue: Save costs and time with intelligent drives

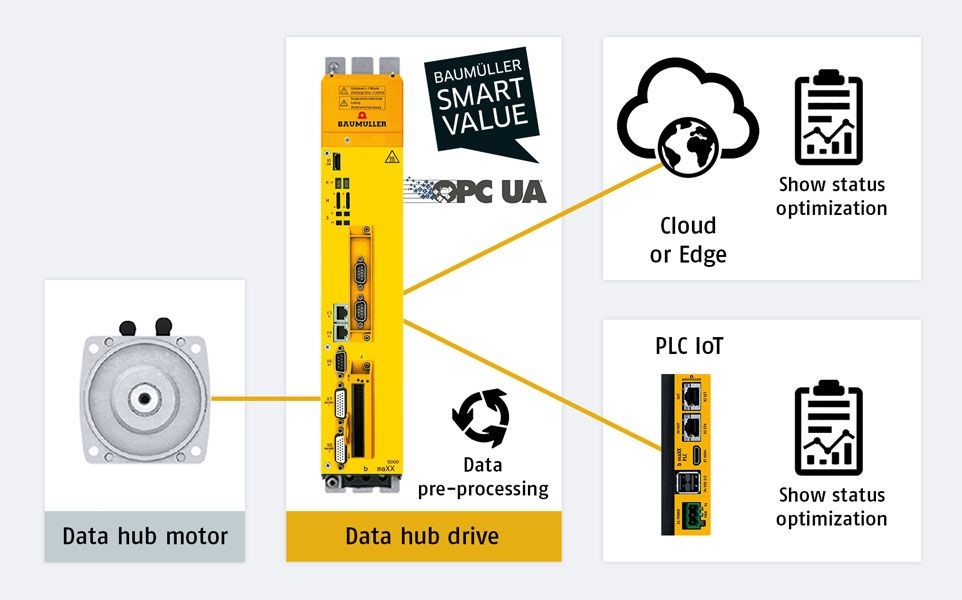

Baumüller SmartValue: Intelligent drives act as a data hub and supply data even without external sensors, e.g. for condition monitoringBaumüller SmartValue stands for the added value offered by the intelligence in the drive for mechanical engineering and the machine operating company/owner. With Baumüller SmartValue, data is collected directly in the process via the intelligent sensor/actuator level, preprocessed, and then used to optimize the process.

Baumüller SmartValue: Intelligent drives act as a data hub and supply data even without external sensors, e.g. for condition monitoringBaumüller SmartValue stands for the added value offered by the intelligence in the drive for mechanical engineering and the machine operating company/owner. With Baumüller SmartValue, data is collected directly in the process via the intelligent sensor/actuator level, preprocessed, and then used to optimize the process.

Data that is already available in the servo drive, such as output, current, torque, speed, or position can now be used to record the motor-drive combination’s current capacity utilization, for example. Existing data can also be used without employing external sensor technology, eliminating costs for additional hardware and the required wiring.

Motors: Fewer mechanical parts and greater flexibility reduce footprint

The demand for a reduced footprint is also driving innovations in the motors product segment. The Baumüller DSD2 series of servo motors was developed for highly dynamic applications with special acceleration capacity requirements as well as for quick-changing start-stop cycles. Available in sizes 28 to 132, this motor can be used, for example, in packaging machines, textile machines, plastics machines, handling units or in robotics. At the trade fair, Baumüller will introduce an overall length extension for size 100. The DSD2 is now additionally available in overall length XO. The new option offers even higher acceleration values and significantly higher performance due to higher maximum and nominal torque.

Baumüller has revised its servo motor series HYG1 for aggressive environments and for industries with very high hygiene, cleanliness and corrosion protection standards and increases flexibility for linking to its customers’ machines. In addition to the B14 flange option available until now, the B5 option is now also offered for connecting the HYG1 to gearing. With this new variant, the motor can also be attached to stainless steel gearings, which facilitates its use in demanding applications, such as in the food industry.

High efficiency, better process performance and low heat development. These are just a few of the advantages of a servo pump in applications such as presses and injection molding machines. In the Standard, Advanced and Performance Line, Baumüller offers its motors in three different motor-pump combinations. The DS2 and DSD2 motors have now also been developed in size 132 with the option of internal toothing, especially for the Advanced Line and the Performance Line, to implement direct attachment on the respective pump. This dispenses with the coupling and pump support as is the case with classic servo pump versions, which has the advantage of a shorter installation length and therefore a smaller machine installation area. Furthermore, direct attachment eliminates the need for mechanical parts. In this way, the machine manufacturer benefits from lower storage costs and a shorter assembly time.

Fig. 2: In a nutshell: Coupling and pump support are not required with direct pump attachment, which also has the advantage of a shorter installation length and a smaller machine installation area, among other things.

Virtual commissioning: New models with hydraulic components shorten development times in the field of servo hydraulics

Baumüller has extended the functional scope of ProSimulation: In addition to the controller and mechanical models, it now also includes models for the individual components of a hydraulic system, such as pumps or piping. This allows complete servo-hydraulic applications to be designed in the simulation and commissioned virtually in order to subsequently transfer the results to the real application. This significantly reduces the time and effort required for the development and commissioning of servo-hydraulic machines and systems. At the same time, this allows the system to be designed for maximum energy-efficiency, and the drive technology can be dimensioned accordingly.

Web & Foil software template saves programming time

Reduces programming work: In addition to the basic functions, the Web & Foil software template also includes functions for the individual process steps of a standard machineWith the Web & Foil software template, Baumüller is rolling out a new template specifically for web-processing machines. The templates include a large part of the required functions. In addition to motion modules, templates are also available for functions such as alarm handling or prepared visualizations. This means that the basic functions do not have to be set up again from scratch, but are instead selected and parameterized directly. Routine tasks such as the instancing of motion modules or linking variables with the modules are no longer necessary. This cuts down on programming time and the developer can focus on the essential machine functions.

Reduces programming work: In addition to the basic functions, the Web & Foil software template also includes functions for the individual process steps of a standard machineWith the Web & Foil software template, Baumüller is rolling out a new template specifically for web-processing machines. The templates include a large part of the required functions. In addition to motion modules, templates are also available for functions such as alarm handling or prepared visualizations. This means that the basic functions do not have to be set up again from scratch, but are instead selected and parameterized directly. Routine tasks such as the instancing of motion modules or linking variables with the modules are no longer necessary. This cuts down on programming time and the developer can focus on the essential machine functions.

Autonomous Mobile Robots (AMR): Increasing productivity in manufacturing and intralogistics

Baumüller Anlagen-Systemtechnik GmbH & Co. KG is the system house of Baumüller. In cooperation with SESTO Robotics, it is strengthening its systems and solutions business through autonomous mobile robots (AMR) for the agile production of the future. The AMR systems are flexible transportation solutions for all kinds of different application areas, such as intralogistics, machine tending, test and diagnostics technology as well as the pharmaceutical and health care sector. The AMRs can be equipped with different payloads of up to 300 kg and increase productivity in production and logistics through shortened walkways, faster transportation times, and flexibility in the use of materials and tools.

Motion Arena: Showroom for drive technology and live meetings

The “Motion Arena” is the Baumüller Group's compact virtual exhibition stand for presenting all its products and solutions and has been extended by a second floor. Customers and interested parties can access information on the latest products, innovative drive and automation solutions, and projects in the digital showroom, either alone or in a guided presentation. The Motion Arena is also a meeting place for live meetings with contacts from sales and engineering.

Lecture on Baumüller SmartValue

A contribution to the topic “Smart Operation Point: Coping with power peaks in electrical machines and systems – without oversizing” will be released to the public on Tuesday, 11/23/2021, from 2:25 – 2:45 p.m. at the On Demand Stage.