Basics: Calculating drive torque (taking all losses within a drive train into account) – theory and practical application

Read min.

Calculating drive torque under ideal conditions, formula, important factors in practice & application examples

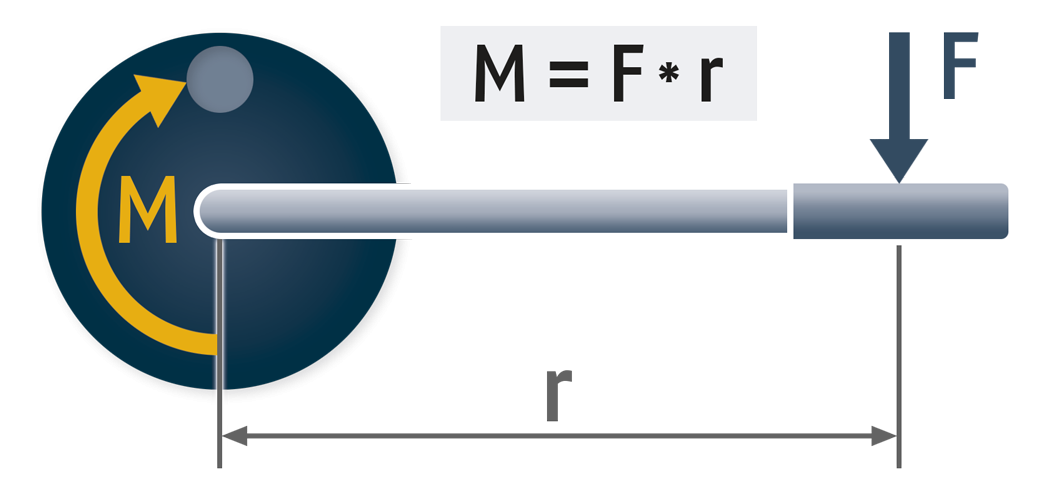

If you want to calculate drive torque, you should first consider it as the torque in motors. Accordingly, the basis for calculation is also the formula for torque. Under ideal conditions, the formula for drive torque would be: M = F x r. Here r is the length of a lever which is attached to the axis of rotation and at whose end the force F acts perpendicularly. However, the point of application can also be arbitrary. In this case it is a good idea to consider the formula as a vector product. In the specific application as drive torque, however, numerous additional factors must be included, such as those arising from frictional forces. These significantly complicate the process of calculation for individual cases. For this reason, these additional factors cannot be generalized.

These factors influence the drive torque

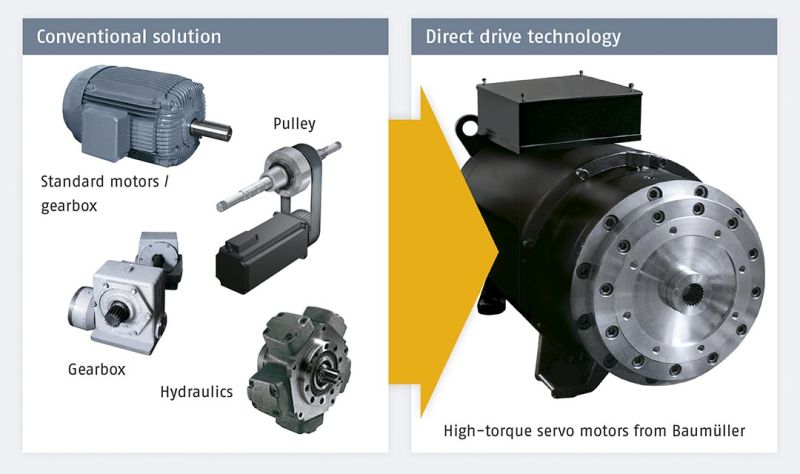

A number of factors are relevant for the calculation. These result mainly from friction losses, e.g. in the transmission. Since the torque is not used in a vacuum in practical applications, the frictional forces act in the opposite direction to the force F. This increases the energy input required to generate the desired torque.

This determines the efficiency. The efficiency represents the proportion of the energy expended that can be converted into usable force. For an electric motor, this means that only a portion of the supplied electrical power remains in the form of mechanical drive power. The technological challenge for us at Baumüller is, among other things, to optimize efficiency in order to develop more energy-efficient drive solutions.

Possible solutions

One option is to dispense with a transmission altogether. Direct drives, e.g. torque motors, are suitable for this purpose. The drives can generate extremely high torques without having to accept gear losses. This also offers advantages over hydraulic systems, since there are no pressure losses. When calculating drive torque, the gear loss factor can be ignored completely. The efficiency reaches a very high level here, which in turn allows greater approximation to ideal conditions.

Further advantages of using direct drives

In practice, it is usually not necessary to calculate the drive torque. Often, it is only important to actually be able to reach a high torque, e.g. in extruders and servo presses. Baumüller high-torque motors achieve torques of up to 60,000 Nm and also offer numerous other advantages beyond high efficiency and thus energy efficiency. These include:

- Fewer emissions

- Smaller operating space

- Less maintenance

- No additional noise insulation required

All in all, they can help reduce costs significantly – on the one hand thanks to their low maintenance requirements and, on the other hand, through their better utilization ratio of expended and actually usable energy.

Matthias Beetz

Training Engineer Academy I Baumüller Nürnberg GmbH