Basics: Field weakening

Read min.

Field weakening is a method for increasing the speed of rotating electrical machines well above the nominal speed. This is accompanied by a drop in torque as soon as the speed exceeds the nominal value. As a result, field weakening is used where high torque is needed at low rotation speeds and lower torque is needed at high rotation speeds.

In these applications, motors with lower nominal speeds can be installed, saving cost and space thanks to smaller components, as well as also conserving energy in most cases. Field weakening can then still increase the speed by a multiple of the nominal speed in order to reach the desired maximum range.

Contents:

Field weakening: Definition and how it works

Electric motors allow a constant torque to be reached in the rotational speed range between 0 and the nominal value. Above the nominal speed, the field may be weakened, with the torque decreasing. At the same time, the voltage remains constant, which is why the speed can be increased far above the nominal value. However, as torque continues to drop, acceleration also suffers.

Example: A motor has a nominal speed of 1000 revolutions per minute. It accelerates steadily from 0 until this speed is reached. From this point onwards, the field weakens and the torque decreases. With the power remaining constant, the speed is now increased above the actual nominal value. However, the time required to accelerate from 1000 to 2000 rpm is now much longer.

The drop in acceleration potential does not have to be negative, however. Especially in industry, there are numerous applications where it has only a marginal to no impact. The effect may even be desired in some circumstances.

Advantages for the user

There are a number of specific advantages for the user. These are essentially based on the fact that lower nominal speeds can be used due to field weakening. These include:

- Reduction in drive sizes

- As a result: Space savings of the drive and all associated components, such as servo controllers

- In addition: Cost savings in manufacturing and purchasing

- Lower energy consumption

- Higher dynamics due to smaller design

As the list shows, the reduction of the nominal speed results above all in a reduction of the drive sizes without having to accept limitations in operation. Of course, this only applies to applications in which the drop in torque at higher speeds does not pose a problem. However, there are numerous examples of this, as described in the paragraph below.

Field weakening in asynchronous motors – comparison with synchronous machines

Field weakening is used differently in PMSMs (permanent magnet synchronous motors) and asynchronous machines. Synchronous machines have a field of permanent magnets, which is why a field current is already present in this case. If we want to further increase the speed, we actively weaken the field current. In asynchronous machines, active current is applied externally anyway.

There is also a difference in the field weakening range. This range is greater with asynchronous machines. However, synchronous machines are more efficient than asynchronous machines, as there is a constant energy flow due to the permanent magnets. They are also more dynamic and allow more rapid acceleration because they exhibit less inertia.

Specific application examples of the principle of field weakening

The use of field weakening involves certain peculiarities in practical applications. Namely, as described above, the speeds available in the upper range are reached to a great extent with field weakening. Since the torque drops sharply in this case, applications for which this is unproblematic are the best candidates. A wealth of applications are possible in both industrial machines and commercial vehicle drives.

A. Industrial machines

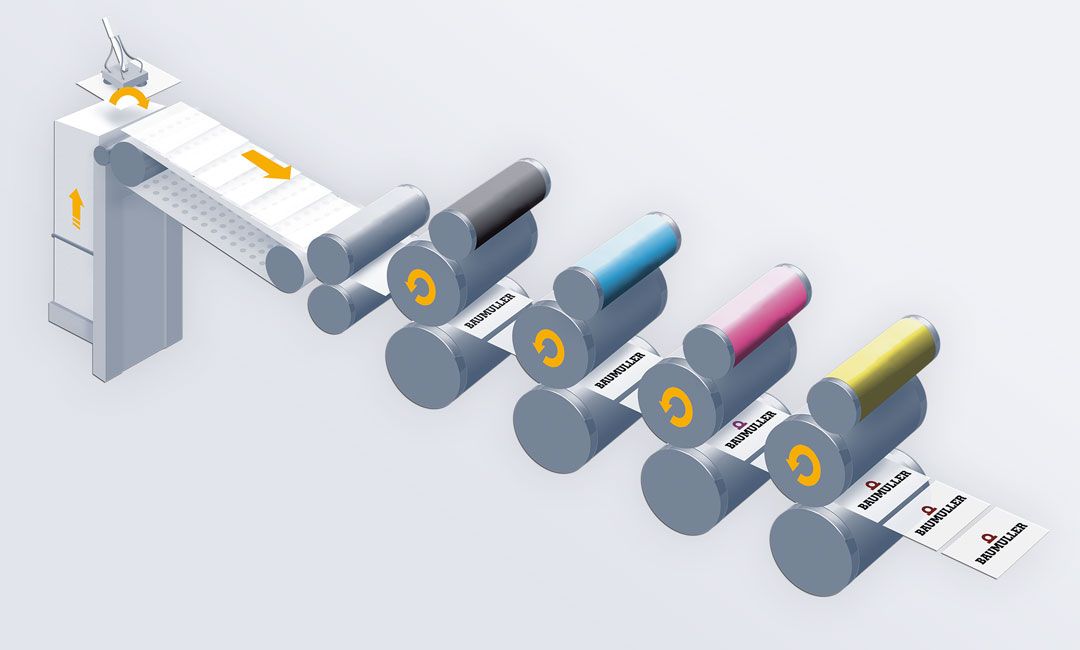

A classic example for the use of field weakening is the drive of a winder. Possible applications include machines on which cables or paper are wound. If material is wound on a roller, for example, a higher rotational speed is required at first, as the overall diameter is initially small. But less torque is also required, since there is still little load being moved.

Example of field weakening in the asynchronous motor of a winding machine

As the diameter increases due to the material being wound, the speed decreases and more load has to be moved. However, as the speed approaches the nominal value, the available torque also approaches the maximum and provides the necessary force. This is therefore a prime example of how the peculiarities of field weakening can be optimally exploited. However, numerous other applications in industry are also possible.

For further clarification, let's consider how a fan works as a counterexample: At a higher speed, the air resistance at the rotors increases, placing greater demand on the torque. More force must be applied the faster the rotation becomes. In such an application, field weakening would be unsuitable.

B. Drives in commercial vehicles

Commercial vehicles are usually relatively heavy and therefore, due to the principle of inertia, require a great deal of torque, especially when starting. At higher speeds, however, this is far less important when the vehicle is already in motion. Moreover, additional applications are often operated at low speeds in these vehicles. Examples include the threshing units of combine harvesters or brushes on cleaning vehicles.

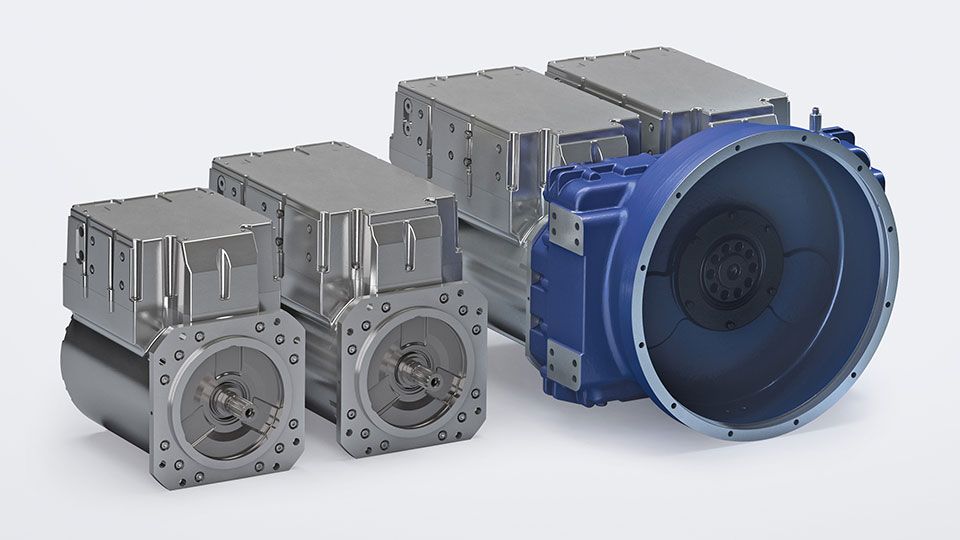

For such applications, Baumüller offers compact, efficient drives, such as the powerMELA, which is operated with a high-voltage battery with 600 volts. The nominal speed in the specific example is 3000 rpm, with a speed of 6000 rpm reached during field weakening. Field weakening is suitable for a wide range of large commercial vehicles, such as those used in agriculture.

Summary

Field weakening allows the use of dimensionally smaller electric drive designs, as their corresponding applications require only low nominal speeds. The speed can be multiplied via field weakening, though at the expense of torque. In industrial machines and commercial vehicle drives, however, this effect can be optimally exploited without major disadvantages. Its use boosts energy efficiency and dynamics while affording an overall improvement of the cost-benefit ratio – thanks above all to the reduced space requirements through the use of more compact designs.

Matthias Beetz

Training Engineer Academy I Baumüller Nürnberg GmbH