Save energy with energy-efficient plasticizing drives

Read min.

Three drive concepts, one objective: To reduce energy consumption during dosing

Manufacturers of plastics machinery are currently facing major challenges. In addition to optimizing productivity and the reliable production of high-quality products, the machines must also be energy-efficient in operation as a result of the increased consideration of total costs of ownership. In the energy-intensive plasticizing process in particular, energy consumption can be significantly reduced by using efficient drive technology. The machine footprint is also a major challenge. This should be as small as possible in order to achieve an improved space productivity for the machine user.

Watch our free Webcast now!

You would like to learn more about this topic?

Detailed information in our Webcast "Efficient drive technology versus rising energy costs – Solutions using the example of the plasticizing drive"

Synchronous direct drives: An energy-efficient and compact alternative

The efficiency of an electric drive depends on the operating point and is therefore a function of speed and torque. It is thus all the more decisive for the energy balance to compare the actual operating points during production with the correlating efficiency levels of the selected drive technology. It is also important to consider potential transmission losses along the entire energy chain in order to find the optimum drive system in terms of energy efficiency.

Due to their consistently high efficiency over a wide speed and torque range, synchronous direct drives are ideally suited for use in plasticizing units. This is because, where direct drives are used, the energy efficiency increases even more at operating points with a reduced torque requirement. Processing different materials results in different operating points and partial load conditions. This further increases the efficiency, thereby improving the energy balance.

Efficiency considerations along the energy chain

A positive side effect: Direct drives eliminate the need for mechanical or hydraulic transmission elements. This has a positive effect on the system efficiency as well as the energy efficiency of the machine. For example, it prevents flow losses in the hydraulic line system between the pump and the hydraulic motor.

With its DST2 high-torque motors, Baumüller offers direct drives with a wide torque and speed range. Thanks to their finely scaled overall lengths, the shaft heights allow for a technically as well as economically optimal design of the electric plasticizing drive.

Direct drive for worm drive

Compact synchronous motor and gearbox combinations

An alternative solution using a spur gearbox is also possible. The energy-efficient synchronous DS2 motor is eminently suitable for a motor-transmission combination. Due to the high speed ranges of the synchronous motor, this combination achieves very good efficiency values and therefore improves the machine’s energy balance.

Another energy-efficient solution is a motor with an integrated planetary gearbox. For example, the compact DSC1-071 synchronous servo motor is a good choice for this variant. With this solution, S3-60 percent torques up to approx. 600 Nm and gear output speeds up to approx. 500 rpm are feasible. This drive unit allows for a much more compact machine design.

Motor with spur gearbox | Photo: KraussMaffei

Synchronous motor with planetary gearbox

Parallel functions are another special feature of electric plasticizing drives. These allow a significant reduction of cycle times and a corresponding increase in machine productivity. This is made possible by an economical and performance-optimized design of the hydraulic system.

The function makes it possible to start tool release already during the dosing operation, thereby significantly reducing the cycle time.

Cycle time reduction through parallel functions in hybrid and electric machines

Choosing an energy-efficient drive topology

The energy balance of the machine and the drive axes depends to a large extent on the drive topology selected.

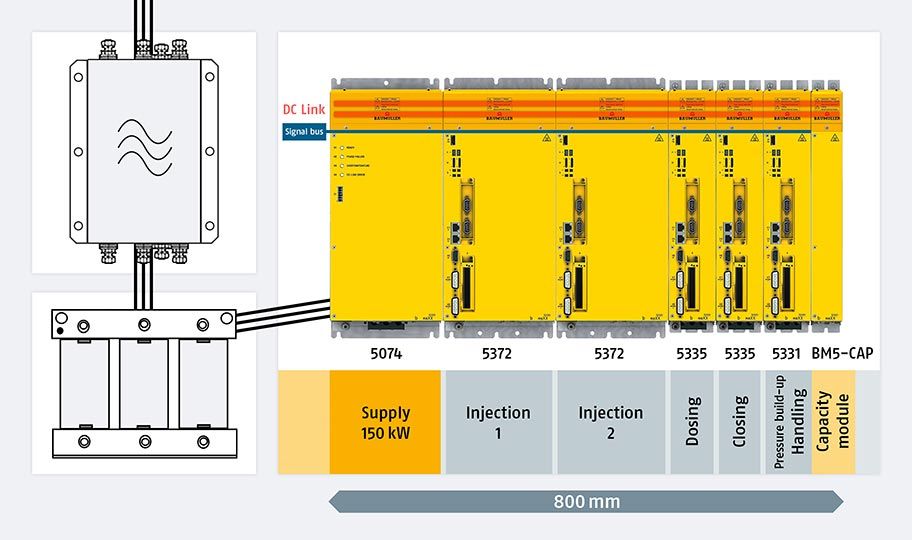

Exemplary representation of a drive topology with feed unit for a fully electric machine

Dynamic axes, such as ejector, clamping, or injection axes, convert the kinetic energy of the system into electrical energy during the braking process. The servo converter feeds the supplied energy into the DC link system and distributes it to the other motor-driven axes, such as the plasticizing drive.

This results in an improved energy efficiency of the entire system and allows energy-efficient operation. Optionally, energy can be fed back into the power supply by a regenerative feedback unit or integrated into a capacity module of the DC link for intermediate storage of excess energy.

In the event of a power failure or during braking, this capacity module can absorb the kinetic energy of the system. After a power failure or malfunction, it is possible to move the drive axes to a defined position depending on the available residual energy and the energy requirement. This prevents damage and accelerates a machine restart considerably.

Conclusion

Compared to conventional solutions, a number of attractive and, above all, energy-efficient alternatives are available for plasticizing drives. Solutions with direct drive technology and planetary or spur gearboxes each have their particular strengths, depending on the requirements of the application.

It is worthwhile to reconsider existing concepts. After all, electrification offers many advantages, such as the elimination of mechanical and hydraulic transmission elements in direct drive technology, high efficiency levels, compact design, and shorter cycle times due to parallel functions. The right choice of drive topology also plays a decisive role when it comes to energy-efficient solutions for the plasticizing unit.

Marcel Möller

Plastics I Baumüller Nürnberg GmbH