Smart extension of the machine life: Detect and successfully prevent wear in the servo-hydraulics in good time

Read min.

Servo-hydraulic drive systems are become increasingly popular as energy-efficient alternatives to classic hydraulics. The speed-variable and very dynamic operation can, however, lead to high loading of the motor and pump. However, these do not have to be at the cost of life and machine reliability, because software helps to prevent wear.

The drives of the Baumüller servo-controllers have different smart functions for servo-hydraulic drives. The automated determination of the pump slip and sensor drift enable conclusions to be drawn regarding the wear condition of the components and to set the parameters for the pump protection functions. Pump wear can therefore be prevented long-term.

Watch the webcast now!

You would like to detect and prevent wear in the servo-hydraulics?

How you can draw conclusions regarding the wear condition of the pump – all the information you need is in our webcast (18 minutes)!

Machine failure due to wear

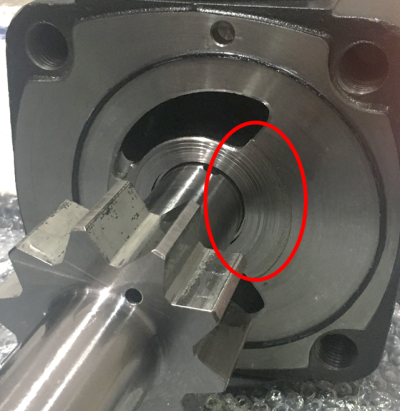

A damaged sealing surface can, for example, lead to pump failure during faulty commissioning

Figure: Baumüller Services

Over time, wear phenomena occur in every system. However, this normally happens so slowly that it remains unnoticed for a long time. Influencing factors such as operating errors or overloads can cause additional rapid acceleration of the wear process.

To prevent pump damage, and ultimately machine failure, it is necessary to detect the wear as early as possible. Only then is it possible to arrange for the components concerned to be replaced and to avert an unplanned machine stoppage.

Pump leak: Deviations from the characteristic curve

With integrated monitoring functions in the drive, Baumüller helps to determine wear phenomena in the pump and pressure sensor. Additional pump protection functions also prevent pump overload or operating errors. In this way, damage to the pump can be prevented, from the commissioning through to series production.

Thanks to the monitoring functions, all wear conditions of the hydraulic pump can be detected, which are associated with a change in pump leakage. Pump leakage is a minor leak within the pump. This is also called pump volumetric loss or pump slip (also pump slippage).

The leak exists in every pump, but the degree to which it is pronounced differs from pump to pump. This leads to the fact that at high pressures, part of the pumped flow rate flows back through the pump and therefore reduces efficiency. I.e. the speed increases while the pressure remains the same. In case of continuously high loading of the pump, the leak also increases with time.

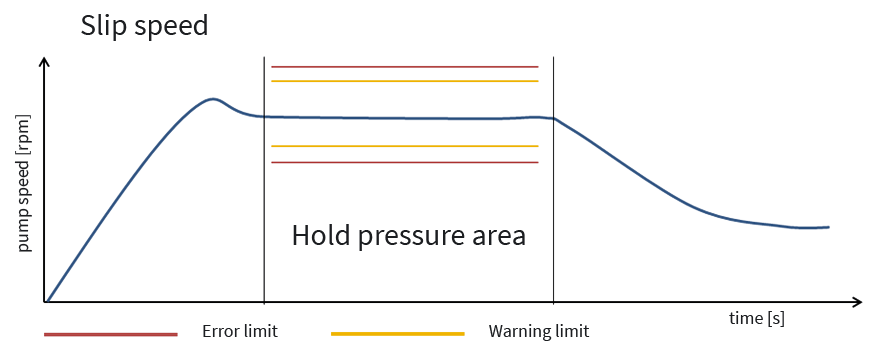

With the help of the pump protection functions integrated directly in the converter, the slip speed is determined and adjusted automatically. Here the determined leak in the drive is readjusted until a warning limit is reached and a warning is output. The operating company is informed automatically, that a pump exchange is necessary. The function therefore increases the availability of the pump, prevents stoppage times and increases process quality.

Automatic determination and adjustment of slip speed: The speed in the drive is readjusted until a warning limit is reached and a warning is output

Sensor drift: Inaccuracy of the pressure sensor

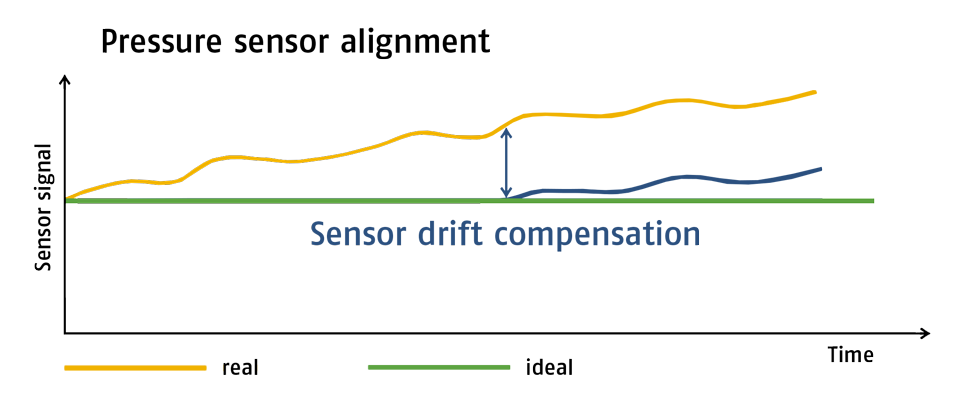

A further wear phenomenon occurs at the pressure sensor. The aging is determined as a result of the increasing sensor drift, i.e. an inaccuracy of the sensor. This is due to an offset in the sensor signal, which grows with the age of the sensor and so increasingly distorts the sensor signal.

Like the pump leak, here too, the sensor drift is monitored by a regular comparison routine. The sensor values are then optimized initially. With increasing inaccuracy and exceeding of a limit value, the wear is detected and necessary sensor exchange is indicated.

Sensor drift monitoring: The sensor value is optimized automatically in case of deviations

Machine dashboard: The characteristics at a glance

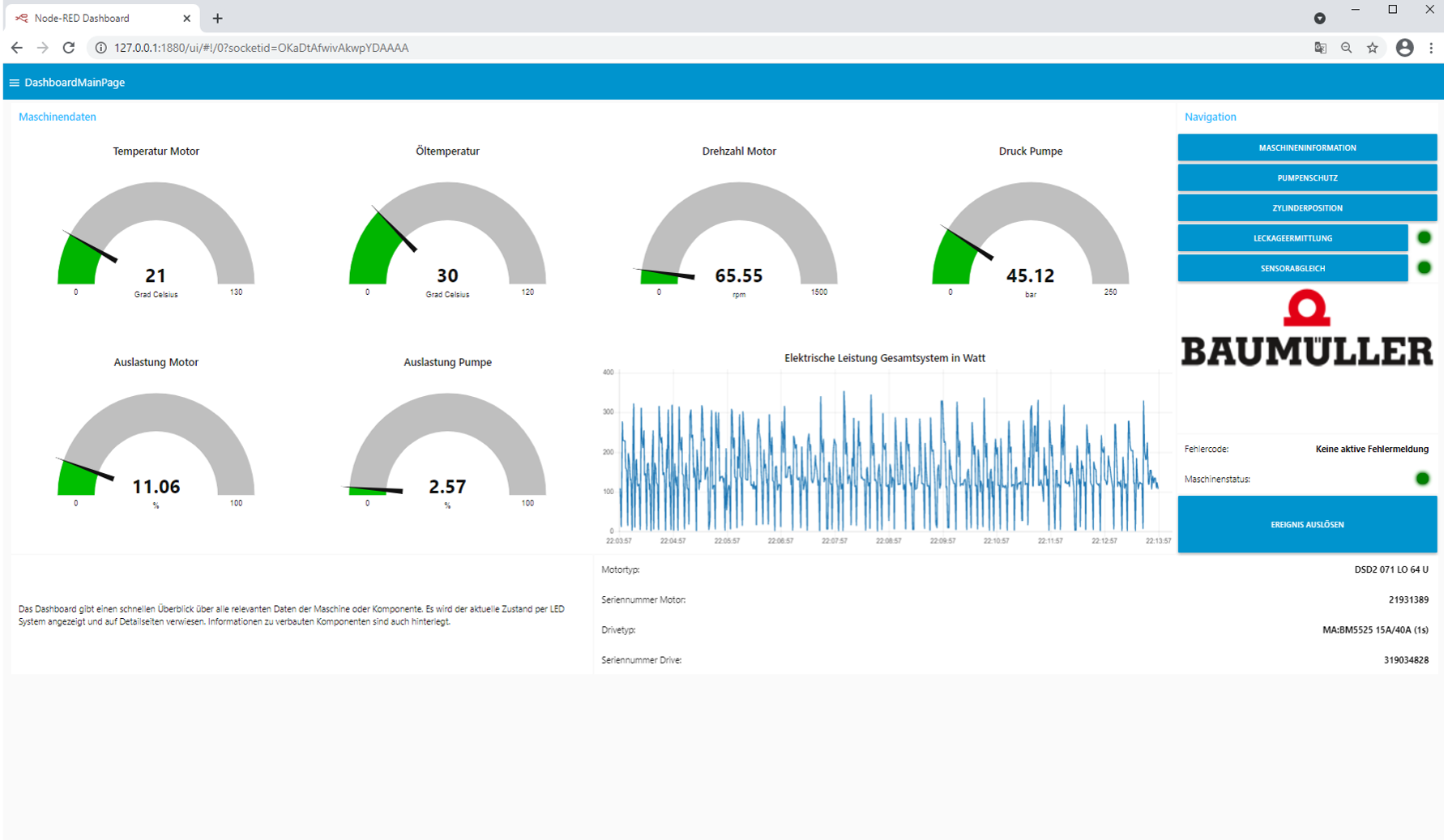

Apart from the hydraulic pump and the pressure sensor, the machines have other drive parameters that it is necessary to keep an eye on during production. With the b maXX PLC IoT control platform of Baumüller, a remote maintenance tool can be used to access the machine data visually.

Scalable control platforms

You can find additional information on our control platforms here

With the help of the IoT interface, a servo-hydraulics dashboard can be created, which provides real-time information about different states and the capacity utilization of the machine. Data such as motor and oil temperature, speed and pressure, as well as the pump capacity utilization are displayed. The values each correspond to the respective actual variable values.

Everything in view: A servo-hydraulics dashboard visualizes the different states and the capacity utilization of the machine in real-time

If a network connection is available, the machine data can also be used online and, for example, stored on a cloud.

Wear detected – wear averted

At Baumüller, the protection functions are integrated directly in the servo-drive in order to avoid wear before it occurs.

Thus, in the event of critical operating states, faults or warnings are generated in good time, or predefined set values are even optimized. Since the pump specifications are checked and the set values are adjusted in advance, wear formation is prevented early.

For example, dry running of the pump is detective due to the lack of a pressure rise when the pump starts up. In addition, the pump protection function detects cable breaks or defective sensors on the basis of the pressure signal and therefore protects the system from overloads in case of failure.

Several protection functions also have the task of not allowing conditions to become critical in the first place. For example, there is an acceleration limit, which protects the pump from speed changes that occur too quickly. The speed set value curves are flattened automatically, before they are implemented by the controller.

The Idle function provides further preventive protection. During pauses, the set values are optimized to achieve pressureless oil circulation and to protect the pump from frequent starts.

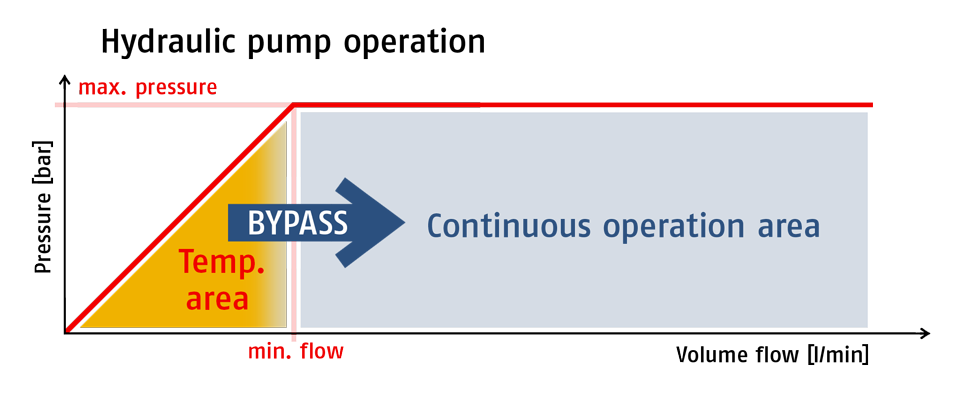

The thermal pump protection is particularly interesting. Thermal overload is particularly likely in case of long dwell times during the machine cycle. This increases wear and can lead to premature pump failure. A temperature model is therefore used to calculate the pump’s thermal capacity utilization. If a threshold value is reached, hydraulic bypasses are connected to relieve the pump. The pump is flushed and damage due to overheating is prevented.

In the case of thermal pump protection, the pump is flushed in good time before overheating, and is therefore shifted out of the critical range

In addition, the integrated protection functions also detect massive faults and switch off the drive in an emergency, in order to protect the hydraulic system.

Commissioning made easy

No special knowledge is required to start up the servo-pump. It is only necessary for the pump and volume set value to be preset by the machine control.

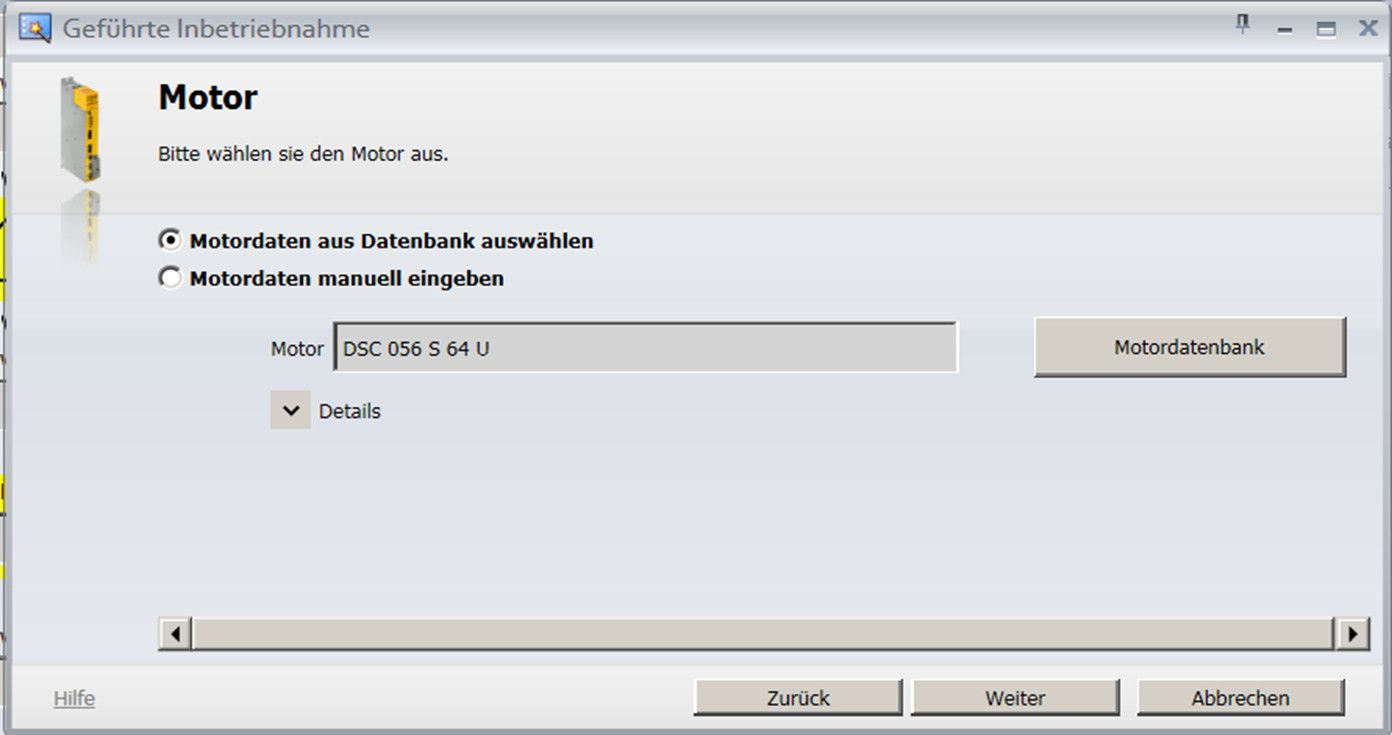

A so-called wizard guides the user quickly and easily through the individual steps of the startup process. Detailed specialist servo-pump knowledge is not necessary for the basic startup. Access to a motor and converter database makes the input of individual parameters superfluous. It is only necessary to select a specific motor/converter combination. The step-by-step guide through the program makes it impossible to forget an input.

With the Wizard, the startup can be accelerated and possible errors or faults can be eliminated. That saves time and money.

The Wizard accesses a motor and converter database and guides the user, quickly and easily through the individual startup steps

A comparison of classic hydraulic drives with servo-hydraulic systems and some application examples

Philipp Gebhardt

Application engineer