Motor damage from oscillation, vibration or shocks? It doesn't have to be like this.

Read min.

Electro motors: how mechanical stressloads such as impacts, oscillation or vibrations affect service life and what means and methods are available to prevent it.

Prevent engine damage from vibrations

Electro motors have a long service life. But what if it isn't enough? Or the motor starts overheating after a short time. The reason could be oscillation, vibration or impacts that affect the motor and significantly reduce its service life. The good news – there is a solution! We can already anticipate problems in the project planning stage and eliminate them from the very start. In this post, we identify the most important factors that limit the service life of electro motors. We go into the problem of mechanical stress loads due to oscillation, vibration and impacts and present solutions for maximizing the motor service life.

Would you like to know what mechanical stress loads shorten the service life of your motors? Visit our Live Webinar on the topic of oscillation loads! There you will also learn what methods are available for preventing damage.

Service life of electro motors

The service life of electro motors is usually equated with the service life of the bearings and for electro motors is around 20.000 hours. But what factors actually influence the service life of motors? Here are the three most important ones:

Temperature:

The problem: high temperatures in the motor damage the lubricants. The lubricants lose their effectiveness => the bearing overheats

Solutions: Baumüller uses high temperature greases that allow high temperatures and thus high rotation speeds.

Bearing currents:

The problem: In motor-converter combinations, bearing currents can develop in some cases. The voltage, instead of grounding through the converter, takes the path of least resistance through the shaft of the motor and the bearings and is discharged towards the ground. This results in vibrations => the bearing overheats and wears prematurely

Solutions: use of common mode chokes and/or current-insulated bearings

Vibration, oscillation, impacts:

The problem: Vibration, oscillation or impacts that impact the motor affect different parts of the drive and can damage different parts of the motor => the service life is shortened, the process quality suffers

Here, too, solutions exist: Vibration measurements and drive simulations offer a remedy. If the stressloads are known, numerous adjusting screws are rotated, which increase the shock resistance of electro motors.

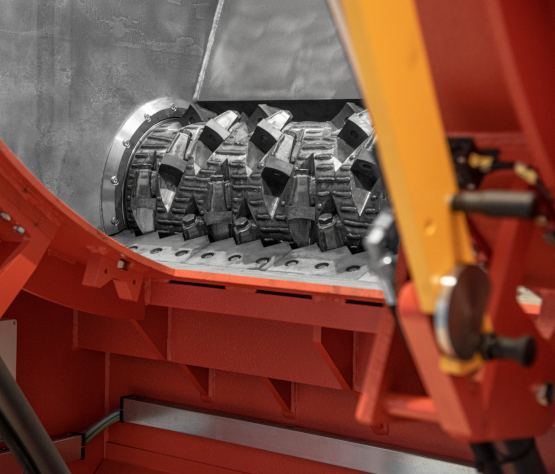

In shredders, motors are exposed to particularly high stressloads. Here it pays to perform an analysis. Fig.: WEIMA Maschinenbau GmbH

Shortened service life through mechanical stressloads

Mechanical stressloads arise in many machines and systems. Known examples are converter machines such as presses and rim bending machines, injection molding machines and extruders, shredders or mobile machines. In these applications there are often few options for absorbing vibration before it reaches the motor and causes damage there. Here teamwork is required: Early cooperation between machine builder and driver manufacturer helps to prevent failures and increase the service life of motors. In sophisticated applications, data on the g-forces that the motor must withstand is often not sufficient to evaluate the full extent of the stressload and correctly estimate the service life of the motor. Experienced simulation engineers include in their analysis the type of mechanical load, the direction of the load, the frequency and amplitude. Another interesting question is where the stressload has its effects, on the shaft or the housing. This way you can differentiate insignificant vibration from shock loads that cause damage. More detailed information on the assessment of mechanical stress loads will be provided in our webcast.

Watch our webcast now!

Motor breakdown? Drive simulation helps.

Effects of vibration, oscillation and shock loads

Whether it is oscillation, vibration or shock load, the effects that result are difficult to predict. Different problems lead to the failure of the motor or to process errors. Damage to the bearing or the windings play the main role here, but there can be other problems:

- Bearing damage: Bearing races develop cracks, rolling bodies are damaged

- Windings: Insulation is rubbed off, short circuits result

- structural damage to the housing

- Crack on the bearing shield

- Damage to the screw connections from the flange to the machine

- Sensor problems: the impact can cause the sensor to lose contact, resulting in signal interruption

When damage occurs, these problems can incur substantial costs and significant losses of time in the market launch of new machines. A better option is to avoid such damage from the beginning. Here drive simulations are helpful in anticipating strong oscillations and any resulting damage right from the project planning phase. Therefore Baumüller carries out drive simulations at an early point in the development phase. The drive expert can then head off problems with structural modifications or modified controller settings. This is possible because of a multi-version motor portfolio with numerous special options and extensive experience in electrical drive technology.

Problem analysis: Measure, simulate, calculate

Close cooperation between machine builder and drive manufacturer is the foundation for the analysis of the problem. With the right data, oscillations, vibrations and impacts can be recognized as a challenge early and their effects can be simulated. In case of an incident, specialists conduct measurements on the damaged motor for damage analysis and fault localization. On new machines, problems with the service life can be anticipated through oscillations or impacts.

In the simulation and interpretation of data, drive expertise plays a central role. Simulation engineers sample different variables:

- Load cycle

- Location of stress on motor

- Is the load radial or axial?

- What is the frequency?

- What are the interactions between the different variables?

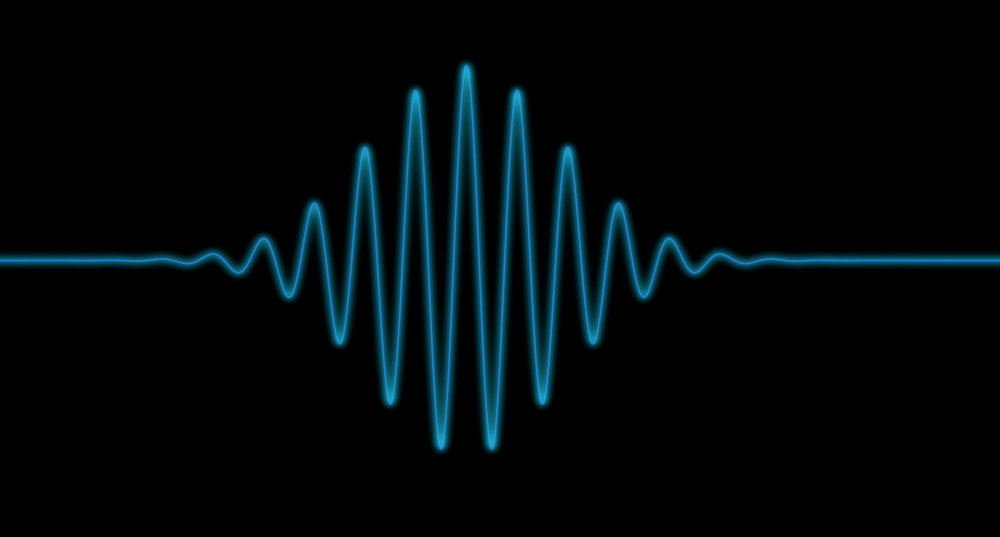

Also, not all forces can be measured on running machines. Only with simulation techniques can these values be calculated and included in the analysis. The FFT analysis is used for the evaluation of data: The FFT analysis breaks down a time signal into individual sine waves and in many areas allows for an optimization of rotating components or an assessment of the wear and tear. The aggregated time signal can then be examined for dominant frequencies. Only certain frequencies cause a dangerous build-up of the motor and are considered critical, while others are harmless. Full steam ahead with simulation: As a specialist with decades of experience in electrical drive technology, Baumüller can model motors with all the relevant characteristics. Information on materials, contacts and connection types is included here. The simulation engineers consider components that are excluded from the analysis using remote mass with the relevant moments of inertia. Structural adaptations can thus be calculated, simulated and checked for their stability with the existing loads. This can be done without having to build and test a prototype.

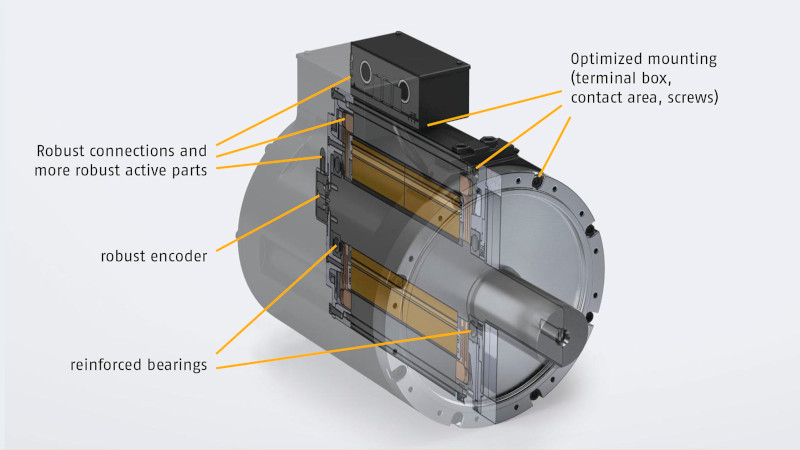

Various adjusting screws are rotated to improve shock resistance on the electro motor

Solution options: Adjusting screws for greater shock resistance

The measurements and simulations then provide the basis for the solution. As a drive manufacturer, Baumüller draws on a broad reservoir of experience and can develop a range of proposals for problem resolution. Example include:

- Adaptations in controlling: Rounding the cycle

- Installing absorbers

- Decoupling the motor (e.g. belt)

- Designing motor more robustly

A few adjusting screws on the motor can be rotated to avoid the effects of vibrations or shocks. Different bearing options, such as deep groove ball bearings, are included as options in the standard portfolio. At Baumüller, with its extensive expertise as a motor manufacturer, a range of other adaptations to the motor are also possible, e.g. reinforced bearing shields or cushioned motor bases.

Industries that have traditionally produced mechanical loads on the motor are well known and already have solutions in the Baumüller portfolio. The high-torque motors DST2, for example, which are available with the integrated thrust bearing. The version with thrust bearing was specially developed for use in extrusion technology: The integrated thrust bearing absorbs the axial forces that act on the motor, which arise from the counter-pressure in the process section. The motor is thus specially designed for these loads and no losses in service life are likely.

High-torque motors DST2

Considerable advantages over motor-gearbox combinations as well as hydraulic systems.

The torque motors DST2 with integrated thrust bearing were developed especially for the high loads in extruders

Teamwork: Efficient

Teamwork pays off. Early cooperation between machine builder and drive manufacturer is recommended for applications where problems commonly arise from process-related shocks or vibrations. This way faults can be calculated beforehand and avoided, thus saving time and costs. Simulation technologies allow for loads to be represented so realistically that proposals can be made on this basis for extending the service life. The modeling of electro motors has become established as an alternative to prototype building, thus saving additional resources. In addition, a spatial independence emerges, which is more and more in demand, thus simplifying collaboration. Simulations also help with error analysis in the event of an incident. The areas of vibration measurement, vibration simulation and drive simulation are part of the Baumüller service spectrum.

Do you have anymore questions?

Florian Tafelmayer

Simulation Engineer