Water-cooled electric motors – In which cases do they make sense? Things to consider

Read min.

Electric motors have a high efficiency of over 90 percent. In other words, a large portion of the electrical energy that is supplied is converted into mechanical output. The remaining approximately 10 percent of the electrical output is lost in the form of heat.

Function and advantages of water cooling

Index

- Functionality of water cooling

- Dynamics

- High torque

- High torque PLUS high dynamics

- Impurities in the air

- High ambient temperature

- Limited footprint

- Temperature-sensitive product

- Water and oil are already in the system

- Strict requirements for hygiene

- Noise emissions must be reduced

- FAQs on water cooling:

- The motor series from Baumüller are available with water cooling:

- Do you have anymore questions?

To prevent the motor from overheating, heat must be dissipated

To prevent the motor from overheating, this heat must be dissipated. For this, a variety of options exist. Uncooled motors dissipate the heat into the machine housing to which they are mounted and into the surroundings via convection. Air-cooled motors have a fan that blows air onto the motor housing, thereby cooling it. Motors with fluid cooling are cooled with water or oil that flows through cooling channels in the motor.

Functionality of water cooling

The fluid cooling of electric motors can be converted in different ways. Basically, there are always ducts in the stator of the motor through which mainly water is conducted because water has the best heat coefficient. For that reason, we refer, both as a rule and also in this text, to water-cooled electric motors. The cooling pipes can either be housed in a special cover or, as in the latest water-cooled servo motors from Baumüller, directly in the motor casing. The version with the cover cooling has the result that the motor needs more space and when realized directly in the housing the dimensions of the water-cooled motors are identical to those of the uncooled motors. In principle, the water is then simply pumped through the motor and repeatedly cooled down again by a cooling unit. Then the motor does not get too hot and can deliver optimal output. The general rule: the more current is fed to the motor, the more the motor heats up and the more the cooling has to do.

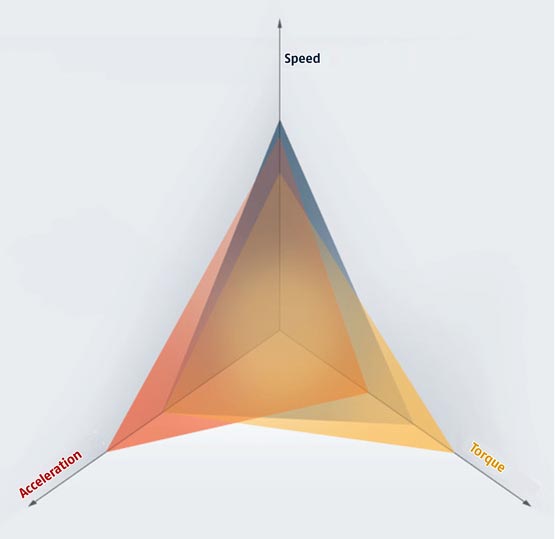

Selecting the right cooling method is not simple. Many factors go into the decision and the reason for the selection of water-cooled electric motors can be varied.

Selecting the right cooling method is not simple. Many factors go into the decision and the reason for the selection of water-cooled electric motors can be varied.

How to video

In the video you will learn what makes water-cooled servomotors special and how you can use them successfully.

10 challenges where the use of water-cooled electric motors makes sense.

Dynamics

Dynamics refers to the way the process requires a rapid start-stop operation with few pauses. The greater the dynamics, the more current has to be supplied, and the drive heats up faster. Water-cooled electric motors are better at dissipating this heat than air-cooled motors, and thus more dynamic processes are possible. Because of the better cooling performance, the motor output is also up to 50% higher than with uncooled motors. This means that in many cases the motors can be smaller in dimensions. Smaller motors have a lower mass inertia and thus also allow for greater dynamics. These good properties of water-cooled motors with respect to dynamics make it possible to reduce cycle times and increase the productivity of machines.

High torque

High torque PLUS high dynamics

Impurities in the air

High ambient temperature

Limited footprint

Temperature-sensitive product

Water and oil are already in the system

Strict requirements for hygiene

Hygienic Design Motors

Noise emissions must be reduced

FAQs on water cooling:

Clear water that is free of suspended matter and dirt is to be used as a coolant, which must meet certain specifications, for example with regard to pH value, water hardness, sulfate content, etc.. However, complex treatment of the cooling water is not necessary for Baumüller electric motors, as the cooling lines are made of the corrosion-resistant materials stainless steel or KTL-coated aluminium. The inlet temperature of the cooling medium (oil or water) is ideally around 25 °C, but can be up to 40 °C, but then derating has to be accepted. However, if the inlet temperature is very low when the outside temperature and humidity are high, then condensation will form. In this case, a small derating at a higher inlet temperature can be accepted in order to avoid the formation of condensation.

The motor series from Baumüller are available with water cooling:

| Motor |

Properties | Installation sizes and water cooling |

|---|---|---|

| DS2 | Three-phase synchronous motor | 100-200 |

| DA1 | Three-phase asynchronous motor | 100-280 |

| DSD2 | Dynamic servo motor for maximum requirements for acceleration capacity and start-stop qualities | 45-132 |

| DSC1 | Compact servo motor with high torque density | 45-100 |

| DSP1 | High-speed servo motor with good acceleration and overload capability and increased speed and output range | 45-100 |

| DST2 | Multipole torque motor as direct drive with very high torque | 135-560 |

Do you have anymore questions?

Markus Keila

Product Manager Motors