Smart Monitoring: Machine data in real time from the drive

Read min.

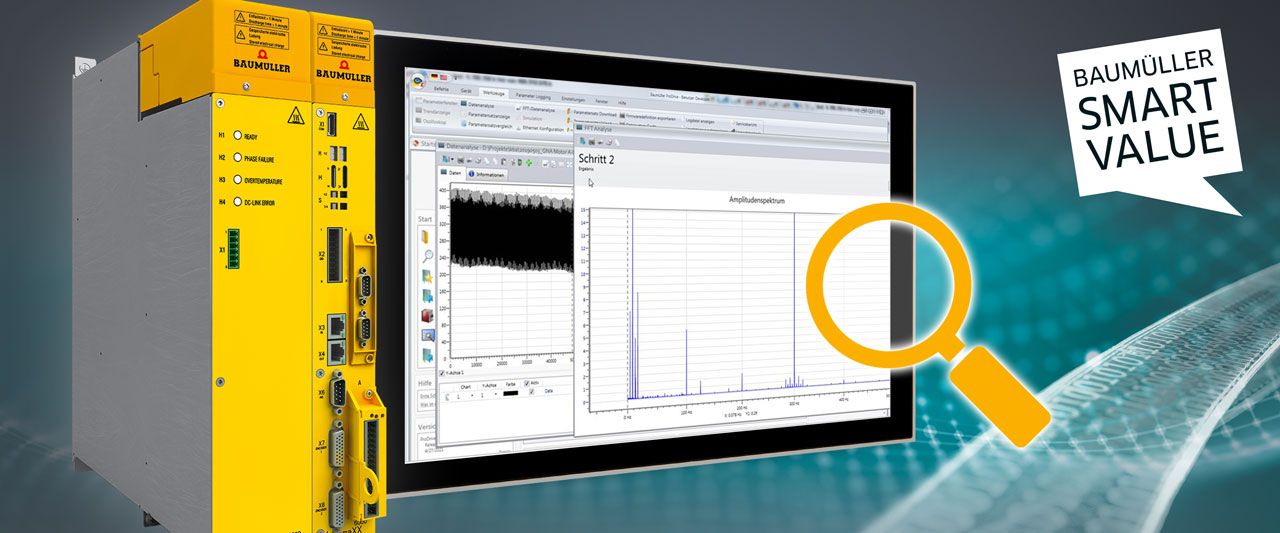

Baumüller Smart Value

Get more out of your drive technology with IoT: Baumüller Smart Value is all about the added value that smart drive technology gives mechanical engineers and machine operators. Baumüller Smart Value enhances the scope of our servo drives: It takes existing data, such as power, current, torque, speed and position, and provides users with important additional information (e.g. machine operating status) or decisions are made directly in the drive to prevent machine failures. The same can be said of the associated design software, which ensures that the motor / controller combination is optimally dimensioned for the respective application and the controller is parameterized. In addition, the design can be immediately verified and optimized on the digital twin using simulation technology.

Baumüller drives have intelligent monitoring functions, which can record all drive parameters in real time down to the controller cycle and forward then to higher architecture layers.

The challenge

The solution

The Baumüller drives have intelligent monitoring functions, which can record all drive parameters in real time down to the controller cycle and forward then to higher architecture layers. The integrated oscilloscope function can be used to forward the device signals, consisting of sample value, timestamp and unit, in manufacturer-independent form, for example, via an OPC UA server. The signals are provided continuously or are triggered. The advantage: The data can be recorded, preprocessed and forwarded directly in the drive. No additional work is incurred for external sensors, additional wiring or a separate evaluation unit such as an Edge PC.

The data recorded in this way can be used later, for example, for quality assurance or for diagnosing a fault. In the Baumüller ProDrive parameterising tool the data can be evaluated with different analysis methods (e.g. FFT and order analysis, waterfall diagram). Another advantage of the Baumüller data analysis using ProDrive is that time-synchronous data acquisition over several axes is also possible.

One use case for Smart Monitoring is the recording of the drive train’s temperature profiles. From this, the capacity utilization of the components used and thus the machine can be recorded. This application can be extended through to detection of problems such as an overload or a defect in mechanical components. This is done by including additional parameters in the monitoring. Fluctuations in motor current and speed can be used to detect mechanical unbalance or loose bearings, bearing damage or changes in the drive train, and to initiate appropriate measures. Worsening of product quality can therefore be avoided and machine stoppages reduced by maintenance work planned in advance.

ProDrive can be installed on all Windows devices. The results are then available in the ProSimulation simulation tool as the basis for optimizations. Parameters can be changed and adjustments verified here.

What Baumüller Smart Monitoring can do

- During commissioning:

- Trigger for specific results or error patterns

- Record “good patterns” as reference

- In operation:

- Continuous recording of measured values

- Detection of deviations from the references

- Automatic detection of changes in repeated/clocked processes

- Detection of unexpected events or their accumulation

- In the service case:

- Determining the causes of faults

- Trigger for specific results or error patterns

- Look back at operation before the fault (history)

Baumüller places particular importance in the high degree of interoperability of its solutions, and is therefore a member of committees working to achieve standardizations for data exchange.

Fast Fourier Transformation

Jürgen Dlugosch

Senior Product Manager I Baumüller Nürnberg GmbH