Smart Protection: A high load-inertia ratio leads to vibrations?! – Simulation helps!

Read min.

Baumüller Smart Value

Get more out of your drive technology with IoT: Baumüller Smart Value is all about the added value that smart drive technology gives mechanical engineers and machine operators. Baumüller Smart Value enhances the scope of our servo drives: It takes existing data, such as power, current, torque, speed and position, and provides users with important additional information (e.g. machine operating status) or decisions are made directly in the drive to prevent machine failures. The same can be said of the associated design software, which ensures that the motor / controller combination is optimally dimensioned for the respective application and the controller is parameterized. In addition, the design can be immediately verified and optimized on the digital twin using simulation technology.

If vibrations occur permanently, this can have negative consequences for individual drive elements such as the coupling or the transmission. Failure of the machine is imminent.

The problem

In applications with an unfavorable load-inertia ratio between the drive and the driven mechanism, vibrations can occur in the drive system. New parameter settings are difficult to make.

The challenge

Use Case 1: Roller driveb

In this specific example, a small motor drives a large roller in order to apply adhesive for the production of corrugated board and to convey it to the next processing step. The crunch point here is a high load to inertia ratio of 1:218, which makes it difficult to parameterize the controller, since the default settings cannot correct the problem. The plant had swung up and the coupling and transmission were already damaged. New parameter settings are difficult to make.

The solution

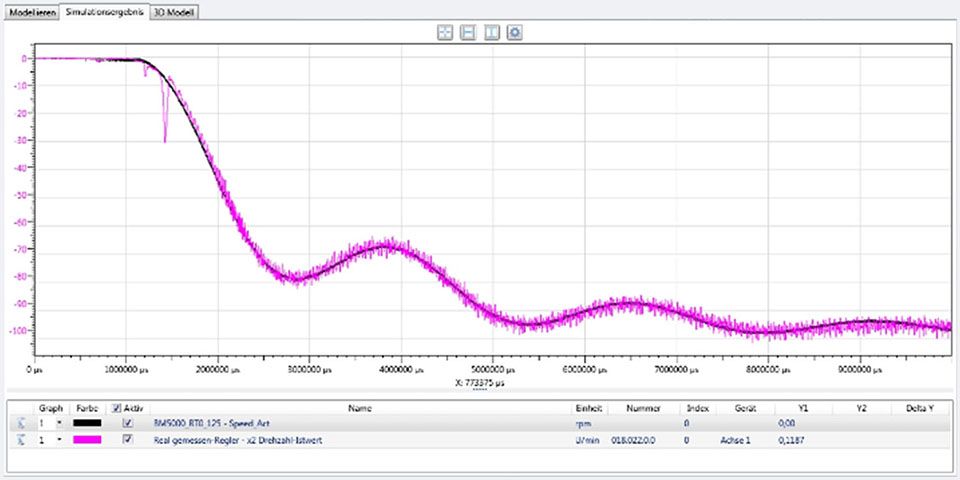

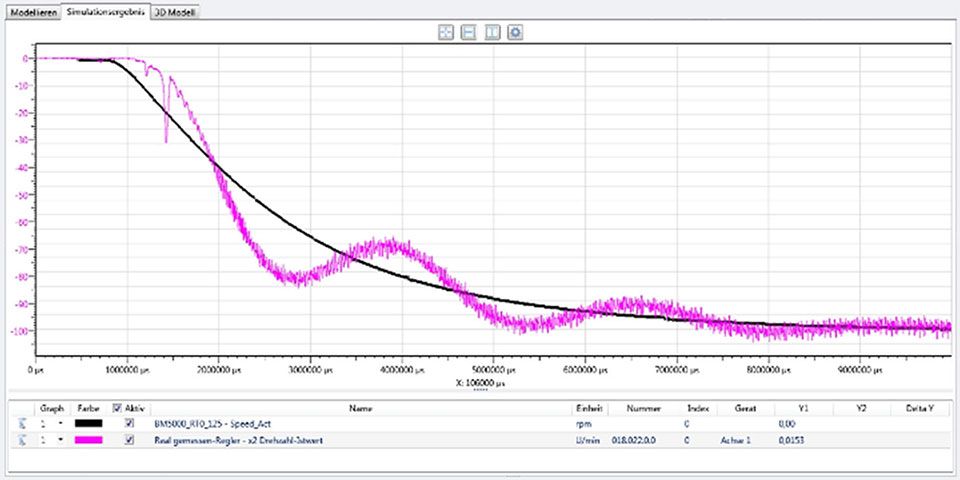

Datasets and measured values were recorded during operation of the machine, which provided information, for example, about the speed and current over time. With this information it was possible to create a virtual simulation model. The data were then read into the simulation. Thus, in the first step, the simulation model could be compared to reality. In the second step, the optimal controller setting was determined safely using the simulation model. This enabled safe operation and optimization of the glue roll’s control behavior.

Real drive data set and real measurement were read directly into ProSimulation. The speed behavior of the real machine (pink) is represented in detail by the simulation model (black). The vibration can be identified in both measurements.

Stefan Hecht

Simulation I Baumüller Nürnberg GmbH