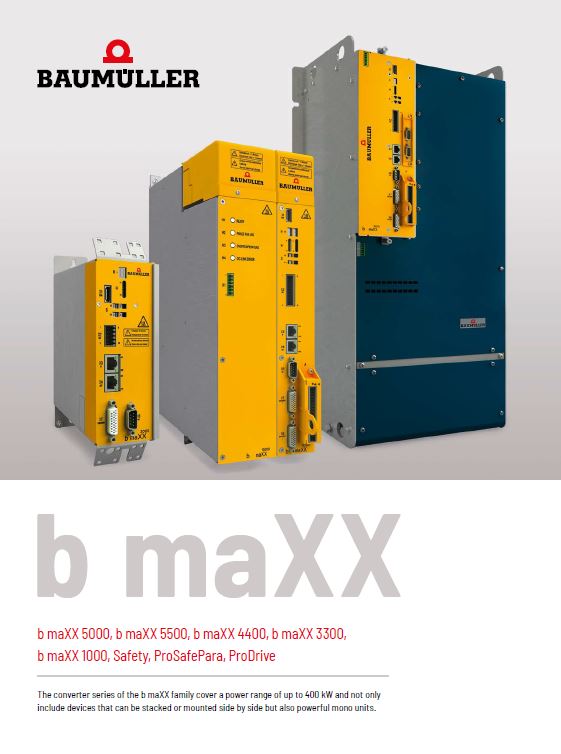

Servo drives by Baumüller

b maXX servo controller family

With its converters, Baumüller provides its customers with important advantages: From cost savings to higher dynamics to increased safety. The converter series of the b maXX family cover a power range of up to 400 kW and not only include devices that can be stacked or mounted side by side but also powerful mono units. With optional safety packs, all devices in this series can be easily adapted to meet your individual safety needs.

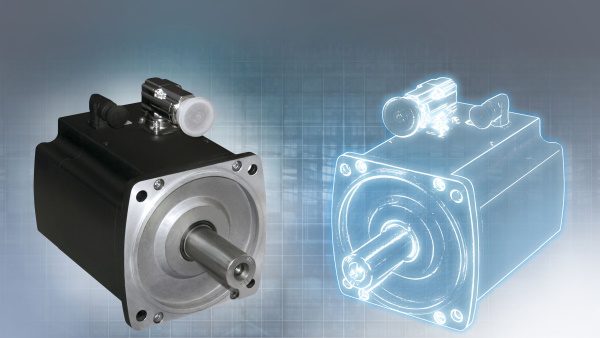

In combination with Baumüller servo motors, you get a drive package that is optimally matched to your application.

b maXX servo drives — Uniquely dynamic and compact

With our servo converters, we already take the future requirements of machines and systems into account in the development phase. For this reason, our high-quality controllers are flexibly expandable and can be easily adapted to changing individual processes. This makes us your strong partner when it comes to full automation for many industry-specific requirements.

Baumüller’s b maXX drive concept is modular, scalable, and open. Its series of servo amplifiers and servo controllers has been developed to meet the current and future requirements of automation technology worldwide. The drive controllers of the b maXX series are the basis for both simple and complex solutions in automation.

With regard to safety, different variants from the simple hardware controlled STO (Safe Torque-Off) through to different higher safety functions, actuated via FSoE (FailSafe over EtherCAT) or hardware I/Os are available, all of which comply with the highest safety level. Both variants can also be combined to set up the secure drive architecture as flexibly as possible.

Baumüller not only offers impressive state-of-the-art servo drive systems, but also complete automation solutions as well as fast service and personal consulting for technical issues.

Drive Intelligence by Baumüller – what is your most important goal?

Shorter product life cycles, growing competition – anyone who wants to survive in the international environment must minimize their development times and shorten innovation cycles. With the b maXX converters we provide you with the competitive edge with which you can achieve this.

1. Implement application requirements with pinpoint accuracy

From the basic device to the full fitout: Match the controller and power unit features precisely to your application. Save time and costs by only configuring and supporting what is really needed.

You can choose flexibly between different encoders, hardware and safety options. Analog and digital I/Os are also freely scalable. From STO to hardware through to higher safety over FSoE, safety applications are adjusted to the respective needs.

A large number of cooling options (air, water, oil and push-through technology) also enables drive dimensioning tailored to the application.

The intermediate circuit capacity is also scalable and, in this way, can be adjusted optimally to the application.

Components such as the ballast chopper or the brake are only included in the device if they are necessary for the application.

The charging circuit can be implemented as a thyristor infeed or as resistor charging. The starting frequency of the thyristor infeed is unlimited whereas, depending on the application, the choke can be omitted for the resistor charging.

2. Set up drive systems flexibly

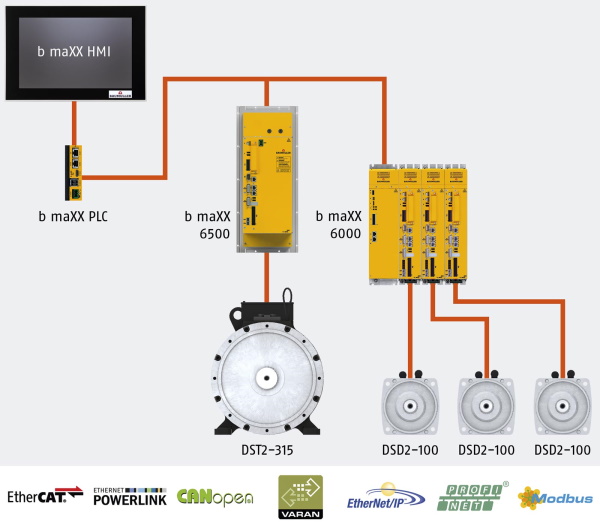

The compatibility of all Baumüller products enables an open and scalable system architecture. You can configure the drive unit individually depending on the power and functional scope required. The modular system of the motors with different shafts, encoder options and fine speed graduation can be combined flexibly with different servo drives. In this way you achieve optimum efficiency for your application.

Baumüller systems and components can be flexibly combined with different machine controls. Our servo drives thus cover all commonly used bus systems, such as VARAN, Modbus TCP, ProfiNet IRT, EtherNET/IP, EtherCAT, and Powerlink.

3. Energy efficient

The dynamic temperature model is implemented as a new function in our servo controllers. It monitors the maximum capacity utilization of the electric drives at power peaks. As a consequence, the devices’ capacity is used better, are dimensioned smaller and, in addition to lower energy consumption, they also provide space and cost savings as well as high machine availability.

Baumüller also implements systems with intermediate circuit group for particularly high peak loads. Thus, process-related peaks can be intercepted and the electrical connected load can be significantly smaller and substantially more cost-effective.

Cooling with water and oil enables simpler removal of the heat losses, lower cost for hall/control cabinet air-conditioning. The control cabinets can be made more compact.

If you opt for push-through technology cooling, the power loss in the control cabinet can be reduced. Depending on the application, there is no need for cost-intensive cooling and air-conditioning there.

4. Reduce footprint

Our new mono devices are extremely compact and are one of the most powerful on the market. The servo controllers therefore need significantly less space in the control cabinet and can be installed in an extremely confined space in the machine. The space savings therefore lead to a significantly reduced machine footprint. If you opt for water or oil cooling you can additionally reduce the installed volume.

By using the single cable solution, the omission of the encoder cable can reduce the wiring effort and save costs.

You can further reduce your control cabinet volume with an intermediate circuit group of the servo axis in combination with grid rectifier/grid inverters.

5. Faster on the market

Speed is decisive – with ProDrive, Baumüller offers a powerful tool for the commissioning and parameterization of your drives. Due to the clear user guidance, you save plenty of parameter input time.

With the drive-integrated “Smart Tuning” function the controller and processing parameters are determined and optimized automatically. The self-optimization reduces the time you expend significantly.

6. Reduce development costs

The mechanical engineering development work and costs can be lowered significantly thanks to digital tools. The parallelization of development cycles produces a considerable time advantage.

Commission your drive system virtually with ProSimulation and optimize the machine directly in the digital twin. Design and systematic errors are identified early and are corrected in advance. The Baumüller drive components are included in ProSimulation as models and enable comprehensive drive simulation.

7. Simplify commissioning

With ProDrive a perfected tool is available for easy commissioning and operation of servo converters. Guided commissioning simplifies parameterization additionally. In particular, you can carry out the initial startup quickly due to the intuitive user guidance of ProDrive.

The consistent standardization is time-saving: The Baumüller servo drives use the ETG (EtherCAT Technology Group) standard for FSoE and support the respective standards of the individual fieldbus systems.

An optional intermediate circuit fuse makes an external intermediate circuit fuse superfluous and further reduces the commissioning effort.

8. Maximize machine availability

Integrated process safety: Functions such as transmission protection, adaption of the controller parameters, fault responses or even controller-integrated monitoring functions such as for servo pump applications ensure lower service costs, shorter standstill times, and lower system costs.

With the parameterizable deceleration ramp (SS1-r) limits can be safely exhausted for sensitive and dangerous applications. The function integrated in the new servo controllers thus leads to higher machine availability.

Fast and easy assembly and dismantling of individual axis modules on intermediate circuit (link) bus, thanks to our Drive Connect System your machine stoppage times are shortened.

Use data already available with Baumüller SmartValue such as power, current, torque, speed or position, for example, to monitor the operating state of the machine. These functions can also be implemented directly in the controller even without external sensors. In addition, decisions can be taken directly in the drive so as to avoid machine failures.

9. Increase productivity

Short controller clock cycles enable, for example, optimal parameterization of the gain factors and thus highly dynamic positioning.

A high field weakening range with simultaneously good control performance ensure optimal and economical drive dimensioning.

An optimal torque-to-inertia ratio of the synchronous motors, the broad speed spectrum and the overload capability enable very high clock rates.

10. Ensure product quality

Virtually cogging torque-free motors, such as the Baumüller DSH1 high-precision servo motors meet the high synchronous operation needs. If high-precision motors are not possible for performance reasons, Baumüller offers the “cogging torque compensation” function integrated in the drive, which enables uniform smooth running even at low speeds.

Highly synchronous set value settings for motion controls thanks to the real-time capable EtherCAT field bus additionally increase precision and product quality.

Oversampling in the encoder evaluation ensures maximum positioning accuracies.

Optimal open-loop control mode achieved by combination of injection, controlled and e.m.f. method ensure the correct rotational direction, a high torque from zero speed and good speed control.

We comply with Ecodesign Directive (EU) 2019/1781 for servo controllers: Our b maXX 1000, b maXX 3000, b maXX 4000, b maXX 5000, and b maXX 6000 family of converters have the required IE2 classification. The relevant data can be found in the respective instruction handbooks for the products under >> Downloads.

Baumüller SmartValue: Smart Functions create added value

Baumüller SmartValue stands for smart functions that promise genuine additional benefits for your machines and processes. Baumüller SmartValue is the added value that smart drive technology gives mechanical engineers and machine operators. This further enhances the scope of the new b maXX 6000 devices.

You will find all the functions at: » Baumüller SmartValue

High-performance drive topologies for sustainable machine concepts

The choice of most suitable drive system depends primarily on the product to be produced on the machine and thus on the machine configuration. The number of axes to be electrified also plays an important role.

The flexible servo converter portfolio enables the appropriately required drive axes to be combined with a power supply or regenerative feedback unit. It is also possible to combine the stacking or side by side technology with a mono device without separate power supply unit, for example, if a very high-powered drive axis is required. The mono unit operates not only as the power supply unit for the axis system but also as the servo drive. The respective systems operate together in a common DC link cluster, which enables energy-efficient operation.

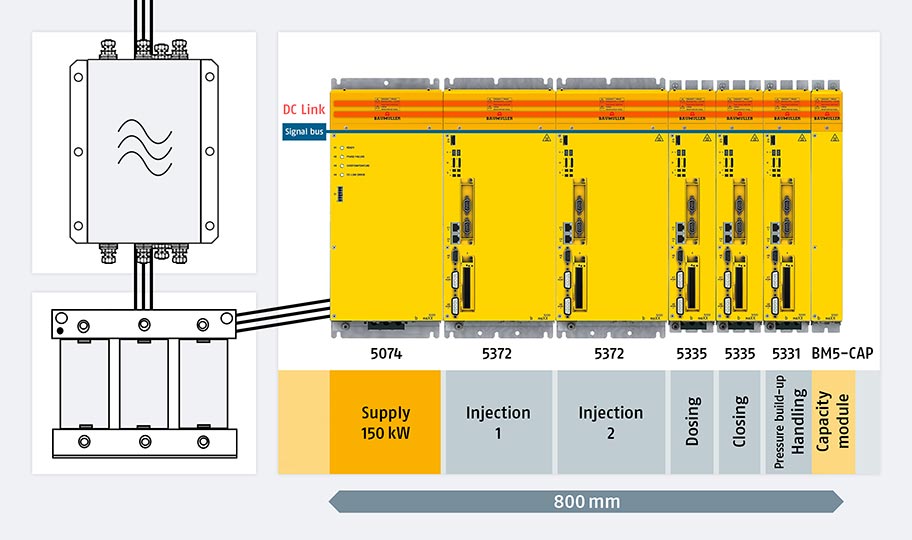

Drive topology with power supply unit using the example of a fully electric plastic injection machine

Drive topology with power supply unit using the example of a fully electric plastic injection machine

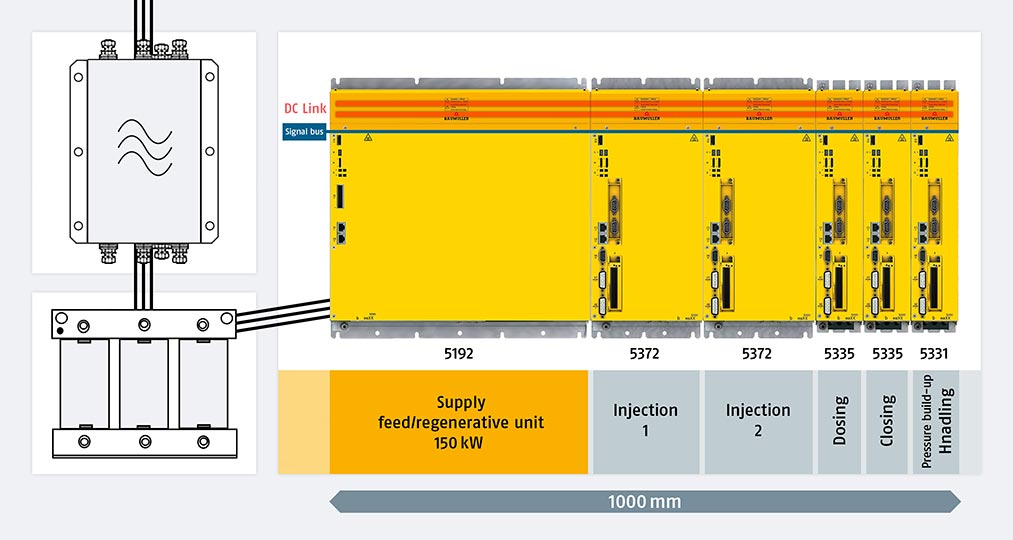

Example of a fully electric plastic injection machine: Drive topology with regenerative feedback unit

Example of a fully electric plastic injection machine: Drive topology with regenerative feedback unit

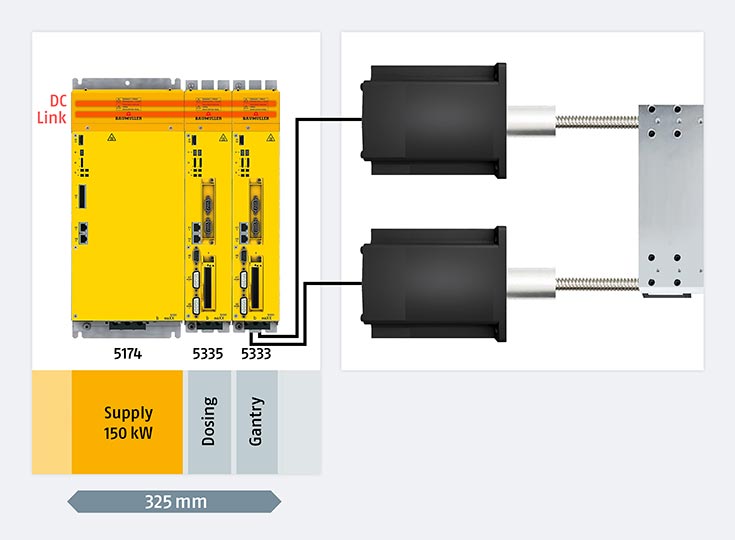

Gantry drive solution

Gantry drive solution

Downloads